Baofeng energy's surge in performance: What Lies Behind the Scale of Production Capacity and High-end Layout? An Overview of Domestic Coal-to-Olefin Projects.

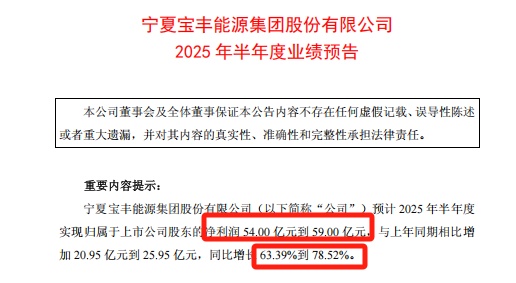

Recently, Ningxia Baofeng Energy Group Co., Ltd. announced2025 semi-annual performance forecast, expecting to achieve a net profit attributable to shareholders of the listed company between 5.4 billion and 5.9 billion yuan, a year-on-year increase of 63% to 78%. The significant increase in performance is attributed to the production launch of the Inner Mongolia olefin project, with a significant year-on-year increase in the production and sales of olefin products.

Baofeng Energy's steady growth in performance is inseparable from its deep cultivation in the coal-to-olefins sector. Behind this achievement lies the strong momentum injected by the orderly advancement of several key projects.

What major projects has Baofeng Energy implemented or is currently advancing? What is the production capacity scale of its high-end olefin products? What new directions is it exploring in emerging industries?

I. Key Project Inventory of Baofeng Energy

As a leading enterprise in the domestic coal-to-olefins sector, Baofeng Energy's project matrix has always focused on extending the coal-based olefins industrial chain. Below is a summary of Baofeng Energy's key projects.

1、The world's largest single-plant coal-to-olefins project.

Baofeng Energy InvestmentThe coal-based new material demonstration project, built at a cost of 67.3 billion yuan, completed its first phase in just 18 months, becoming the world's largest industrial chemical plant for producing polyethylene and polypropylene from coal instead of oil. It has an annual production capacity of 3 million tons of olefins, 1.5 million tons of polyethylene, and 1.5 million tons of polypropylene, accounting for 23.4% of the national total output. Compared to oil-based olefin projects, it has significant cost advantages and market competitiveness.

June 16, 2025The largest coal-to-olefins project in the world at a single plant scale.A grand production commencement summary conference was held in Ordos City, Inner Mongolia, marking the official transition of the project into a new development phase. For Baofeng Energy, this signifies...After the project is completed, the total production capacity of coal-to-olefins will be significantly increased to5.2 million tons per year, approximately 2.4 times the current capacity, will become the largest capacity in the domestic coal-to-olefins industry.

It is worth mentioning that,All the equipment and devices used in this project are produced and manufactured independently by our country, achieving import substitution.23 key core equipment have reached international top levels, creating five global maximum single-unit capacities in gasification, purification, methanol synthesis, full-density polyethylene, and methanol-to-olefins separation coupled steam cracking units, as well as three national maximum single-unit capacities in DMTO, polypropylene, and air separation units. This injects strong momentum into the high-quality development of China's equipment manufacturing industry and supports the construction of a "strong manufacturing nation."

Baofeng Energy Inner Mongolia Coal-Based New Materials Project Purification Device

2. High-end coal-based chemical demonstration projects (including polyvinyl alcohol, POE, MMA, PC, etc.)

In May 2025, with a total investment of 19.8 billion yuan! A new project by Ningxia Baofeng Energy has been announced, namedHigh-end coal-based chemical products demonstration projectThe construction site is located in the Linhe Comprehensive Industrial Park of the Ningdong Energy and Chemical Base in Ningxia.Area A.

The construction scale is an annual output of200,000 tons of polyvinyl alcohol, 200,000 tons of POE, 200,000 tons of MMA, 260,000 tons of PC, 800,000 tons of acrylic acid and esters, and other products.

Mainly build air separation, gasification, purification, methanol synthesis, sulfur recovery, methanol to olefins.Production facilities for α-olefins, POE, vinyl acetate, polyvinyl alcohol, MMA, acrylic acid and esters, phenol/acetone, bisphenol A, polycarbonate, etc., along with the construction of public utilities and auxiliary production facilities.

3. New-type energy storage cathode, anode, and electrolyte factory project

On April 27, 2025, the concentrated construction site promotion meeting for the Baofeng Energy storage positive electrode, negative electrode, electrolyte plant, and Baofeng Energy Phase IV olefin new materials project was held at the Ningdong base.

Total investment in the new type of energy storage positive electrode, negative electrode, and electrolyte plant project10.5 billion yuan, the project will accelerate the construction and production of 250,000 tons of lithium iron phosphate cathode materials, 150,000 tons of artificial graphite anode materials, 170,000 tons of electrolyte materials, 100GWh lithium batteries and energy storage systems, and energy storage station projects.

Baofeng Energy Storage Cathode Factory

Baofeng Energy Storage Anode Factory

Baofeng Energy Storage Electrolyte Plant

II. Key Domestic Coal-to-Olefins Projects

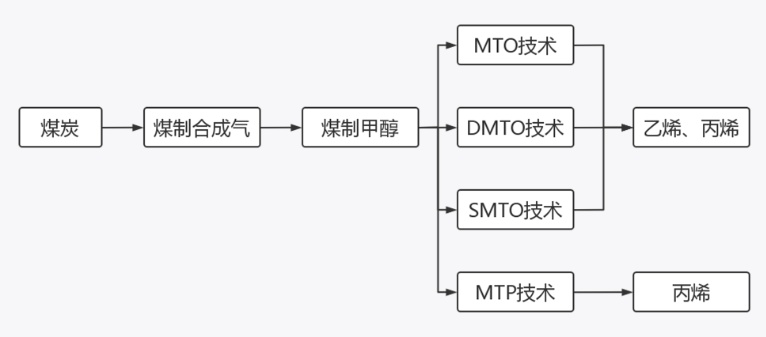

Coal-to-olefins is one of the important technological processes for producing olefins in China. It uses coal as raw material to first produce methanol through gasification, conversion, purification, and synthesis processes, and then produces olefins (ethylene) from methanol.(plus propylene), and then produce polyolefins (polyethylene, polypropylene) and other downstream products.。

Coal-to-olefinsCTO includes coal-to-methanol (CTM) and methanol-to-olefins (MTO), with the main process being coal → synthesis gas → methanol → olefins.

Below, Special Plastic Vision will take you to review the domestic coal-to-olefins projects.

1. Zhongtian Hechuang Coal-to-Olefins Project

Zhongtian Hechuang is one of the largest coal-to-olefins projects in China, using the methanol-to-olefins technology developed by the Dalian Institute of Chemical Physics, Chinese Academy of Sciences.The DMTO technology has an annual production capacity of 1.37 million tons of ethylene and propylene. This project has achieved energy optimization across the entire process, with a significant increase in the efficiency of by-product utilization, making it a benchmark for modern coal chemical industry.

2. Shenhua Ningmei Coal-to-Oil and Olefin Project

Shenhua Ningmei is the world's largest single-set coal-to-olefins project, employing methanol-to-olefins technology, with an annual production of ethylene and propylene.1.36 million tons, and achieve green manufacturing through exhaust gas recovery and wastewater treatment, reducing carbon footprint and contributing to the country's "dual carbon" goals. The construction content includes methanol production using gasification technology, olefin production and polyolefin using DMTO-II technology, adding an annual production capacity of 800,000 tons of high-density polyethylene, and enhancing the overall level of circular economy and green chemistry.

3. Yanzhou Coal Yulin Coal-to-Olefin Project

The Yulin project of Yanzhou Coal Mining Company produces ethylene and propylene through methanol-to-olefins technology, while also developing downstream products such as polypropylene and polyethylene. The project utilizes an efficient water-coal slurry gasification process, with a water resource utilization rate that is at the industry-leading level. The project has a designed annual output of...600,000 tons of polypropylene and 400,000 tons of polyethylene, along with the addition of waste gas treatment facilities and green low-carbon transformation, will comprehensively enhance environmental protection and energy utilization efficiency.

4. Yanchang Petroleum Coal Chemical Project

Yanchang Petroleum has established a large coal-to-olefins base in Yulin, focusing on downstream deep processing of methanol to olefins, promoting the diversification of the industrial chain. The project integrates local coal resources with new energy development, forming a resource recycling system. The project uses self-developed gasification technology, with an annual production capacity of...600,000 tons of polyethylene and 500,000 tons of polypropylene, along with the construction of carbon dioxide capture and storage (CCS) facilities, as well as a methanol production facility with an annual output of 300,000 tons, to promote green and low-carbon transformation.

Shandong Energy Yanzhou Mining 800,000 tons/year coal-to-olefins project in Xinjiang

The project is currently in the overall design stage. The total investment of the project20.858 billion yuan, the main project includes 13 production units such as air separation, gasification, conversion, low-temperature methanol washing, sulfur recovery, methanol synthesis, methanol to olefins, olefin separation, steam cracking, 1-butene, polyethylene, polypropylene, and electrolysis water devices.

6. Xinjiang Sheneng Chemical 800,000 tons/year coal-to-olefins project

The project is inApproved in February 2025, the first phase is currently under civil construction, with a total investment of over 20 billion yuan. It involves the use of coal gasification under pressure combined with green hydrogen technology, producing 800,000 tons of olefins annually, which include polyethylene and polypropylene, along with supporting air separation and sulfur recovery units.

Editor: Yun Shimeng (Carrie)

Source: Jingyan Chemical Platform, Polyolefins People, Olefins and High-end Downstream, Process Industry, New Energy and Environmental Protection

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."