Chemical fiber giant invests 100 million yuan in fdca, life bio's valuation soars to 1.5 billion!

This capital marriage not only represents a key layout for Xin Fengming's strategy of "greening, differentiation, and innovation," but also marks a new stage in the industrialization process of biobased polyester materials in China. Relying on Lif's technological accumulation in the field of FDCA (2,5-furandicarboxylic acid), the two parties have previously achieved large-scale production of 100% biobased polyester PEF filaments, providing a feasible technological path for the green transformation of the textile industry.

1. The underlying logic of investment, breaking through homogeneous competition.

The recent investment by Xin Fengming is not a coincidence. As a leading global enterprise in polyester fibers,The total market value has reached 17 billion yuan, and its traditional core business is facing increasing pressure from intensified homogenization competition. Biobased materials are seen as an important direction to break through this "involution." The announcement clearly states that the core investment goal is to explore the application of PEF in high-end biobased fibers, green packaging, and other fields through Lifu Bio's FDCA technology, which aligns closely with New Fengming's strategy of "consolidating traditional industries + laying out emerging industries."

Lif Biological's core value lies in its technological barriers for furan-based bio materials. Since its establishment in 2014, the company has focused on the R&D of FDCA and downstream PEF, having built the world's first thousand-ton FDCA production line and a hundred-ton continuous production line. The ten-thousand-ton production line currently under construction is expected to be operational by the end of 2025, making it the largest FDCA supplier globally upon commissioning. More importantly, its technological path has broken through industry bottlenecks—by using the "glucose-HMF-FDCA" process, it has eliminated reliance on expensive raw materials, and the product purity reaches 99.99%, with polymerization performance leading the industry.

This technological advantage is directly reflected in the valuation logic: Liv Biology's post-investment valuation reached 768 million yuan in its B1 round in 2023, with the pre-investment valuation already reaching 1.2 billion yuan, and the post-investment valuation now exceeding 1.5 billion yuan. The announcement explains that the valuation increase is supported by four core factors: the maturity of continuous processes using glucose as a raw material, globally leading FDCA quality, delivery capability advantages from a ten-thousand-ton production line, and a clear cost reduction path—FDCA prices are expected to drop to 50,000-60,000 yuan/ton by 2025 and further reduce to 20,000-30,000 yuan/ton after 2027, gradually approaching the cost of petroleum-based raw materials.

2. Technological breakthroughs + capital support, PEF is about to be industrialized.

Biobased polyester PEF is regarded by the industry as the best alternative to petroleum-based PET. Its chemical structural similarity to PET means it is compatible with existing production equipment, while its performance advantages are even more significant: in addition to the low-carbon properties brought by being fully biobased, PEF fibers exhibit outstanding performance in moisture absorption and quick drying (with a moisture absorption rate more than twice that of PET) and natural antibacterial properties (with an antibacterial rate exceeding 99%). This demonstrates great application potential in fields such as sportswear and medical textiles.

Image source: Livzon Biological Products

Image source: Livzon Biological Products

The breakthrough in large-scale mass production is the result of the combination of New Fengming's industrial capabilities and Liv Biotech.

Livzon Bio provides core raw material assurance: its FDCA product has a purity of 99.99%, exhibiting more stable reactivity during the polymerization process, laying the foundation for the physical properties of PEF filaments.

Xin Fengming contributed to mass production experience: As a polyester production expert, it solved process challenges such as melt flow and stretching stabilization in the PEF spinning process, transforming laboratory technology into industrial production capacity.

According to OECD forecasts, by 2030, biobased products will replace 25% of the organic chemicals market. As PEF is the biobased material closest to PET, it is expected to rapidly penetrate fields such as textiles and packaging. Through this investment, Xinfengming secures FDCA supply, effectively obtaining a "ticket" to the industrialization of biobased materials in advance.

3. Opportunities and challenges coexist, and Livzon Bio continues to incur losses.

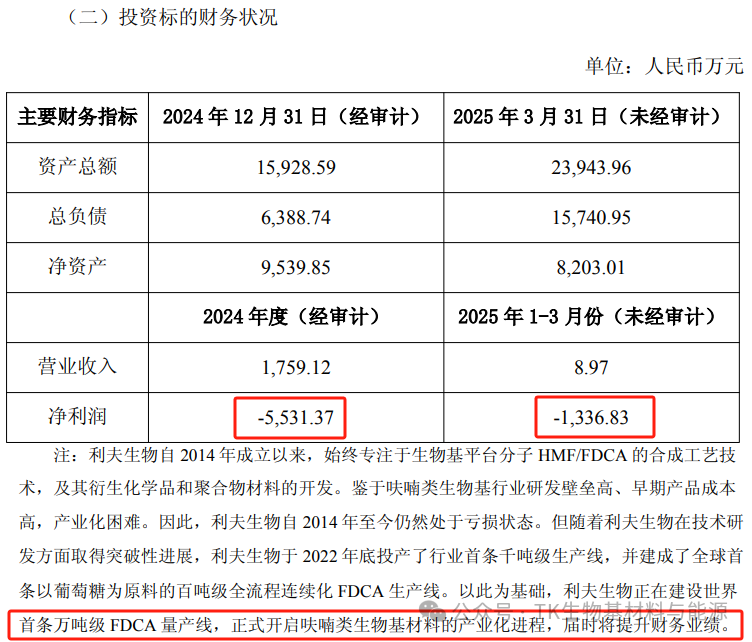

Despite the promising prospects, this collaboration still faces many challenges. The announcement clearly points out three major risks: 1. Market uncertainty: The acceptance and price sensitivity of bio-based materials need to be tested by the market; 2. Production line commissioning risk: If Liv Biotech's ton-level FDCA production line cannot be commissioned on schedule, it will affect the scaling process of PEF; 3. Revenue cycle issue: Liv Biotech has been continuously losing money since its establishment (with a net profit of -55.3137 million yuan in 2024 and a net profit of -13.3683 million yuan from January to March 2025), making it difficult to contribute profits to New Fengming in the short term.

However, as technology continues to mature, these risks are gradually being mitigated. Livbio's losses primarily stem from early-stage research and development investments. With the production line reaching a capacity of tens of thousands of tons and costs declining, the profitability outlook has become clear. Xin Fengming also controls risks through a "stakeholding rather than controlling" approach, while retaining flexibility for technical collaboration. More importantly, both parties have formed a closed loop of "technology research and development - raw material supply - mass production implementation": Livbio is responsible for reducing FDCA costs, while Xin Fengming is responsible for expanding PEF application scenarios. This division of labor model provides sustainable momentum for industrialization.

4. FDCA industry financing heats up, capital races in the biobased track.

FDCA, as the core raw material for bio-based polyesters, has become a popular track for capital competition. From the perspective of industry financing, multiple companies have received capital injections at different stages: Lif Biological has recently received 100 million yuan in C-round financing from New Fengming; Sugar Energy Technology is set to complete its B+ round financing in 2024, although the amount is unknown, it is supported by Zhoushan Financial and Daishan Investment Group; Zhongke Guosheng secured 200 million yuan in A+ round financing in March 2025, with CITIC Jinshi and PwC Capital participating; Yunshang New Materials, Sairike, and Yujun Biological have also received capital favor in the Angel+, Angel+, and B round stages, respectively.

Behind the capital-intensive layout is a long-term optimism for bio-based materials to replace petroleum-based materials. Different rounds of financing reflect the development stages of enterprises: the angel round focuses on technology validation, rounds A/B promote capacity landing, and round C accelerates industrial expansion. New Feng Ming's investment in Lifa Bio is not only a strategic extension for itself but also in line with the rising trend of financing in the FDCA industry. It leverages capital to deepen its bio-based polyester layout and works with other companies in the industry to promote the FDCA-PEF industrial chain from technology research and development to large-scale application, seizing the initiative in the green materials revolution.

With the commissioning of Livan Bio's 10,000-ton FDCA production line and the expansion of PEF application scenarios, this investment, which began with technological cooperation, is expected to reshape the global polyester material competition landscape. As stated in the announcement, this is not only a choice for enterprises seeking new momentum but also a practice of "contributing new qualitative power to the green development of the global textile fiber industry."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.