Intelligent and Energy-Efficient Dual Empowerment | Lijin Injection Molding Machines Showcase Electric and Green Energy-Saving Injection Molding Solutions in Turkey

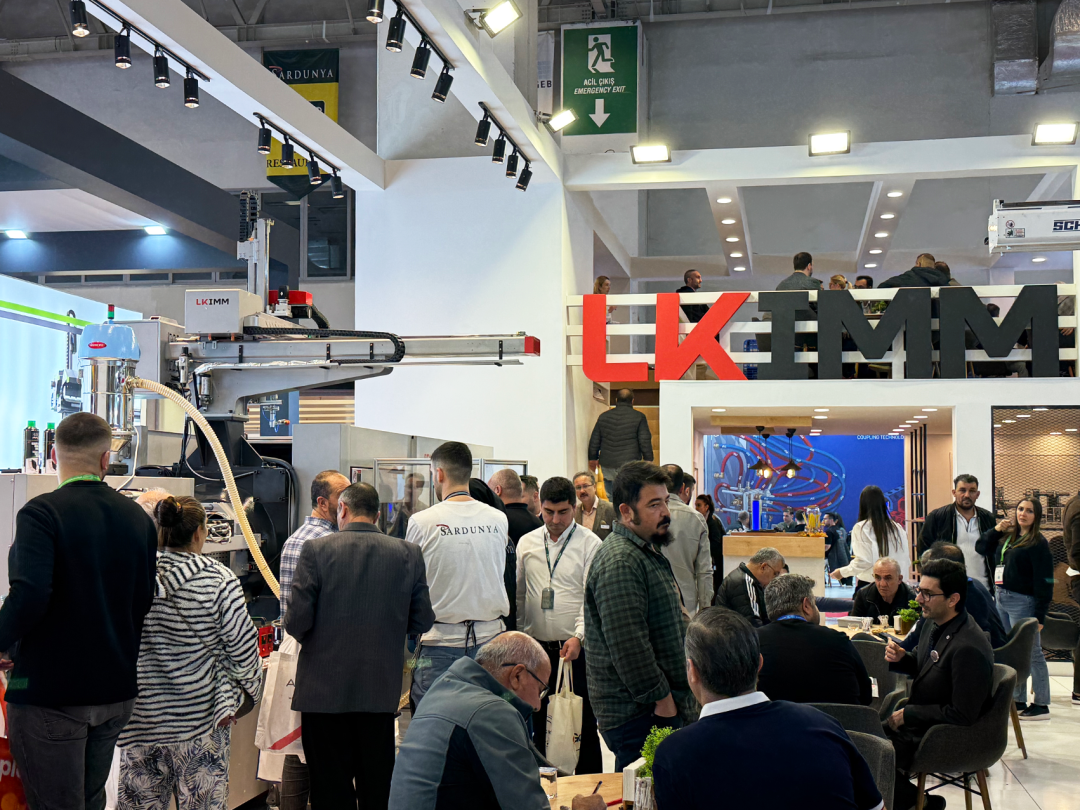

Recently, 2025 TurkeyThe International Plastic Industry Exhibition is held in Istanbul.More than 1,000 companies from Europe, America, Asia, the Middle East, and other countries and regions participated in the exhibition, becoming a barometer for the plastic industry market across the Eurasian region.

Turkey's rapidly developing economy has driven the demand for plastic and rubber products and related industries. At booth 1123 in Hall 11, Lijin Plastic Machinery showcased the ELS400 electric high-speed thin-wall packaging machine and PTA320 servo energy-saving injection molding machine. They connected and communicated with buyers, manufacturers, and technical experts from around the world to discuss cutting-edge technologies, market trends, and sustainable development strategies.

ELS400 Electric High-Speed Thin-Wall Packaging Machine

Widely used in the fields of food, medical, cosmetics, optics, and electronic products, equipped with high-torque servo motors and servo hydraulic technology, the injection platform is configured with linear guides, providing low resistance and low energy consumption. The opening and closing speed of the mold can reach over 1500mm/s, and the injection speed can reach 500mm/s, meeting the production requirements for high quality, high precision, and ultra-thin products.

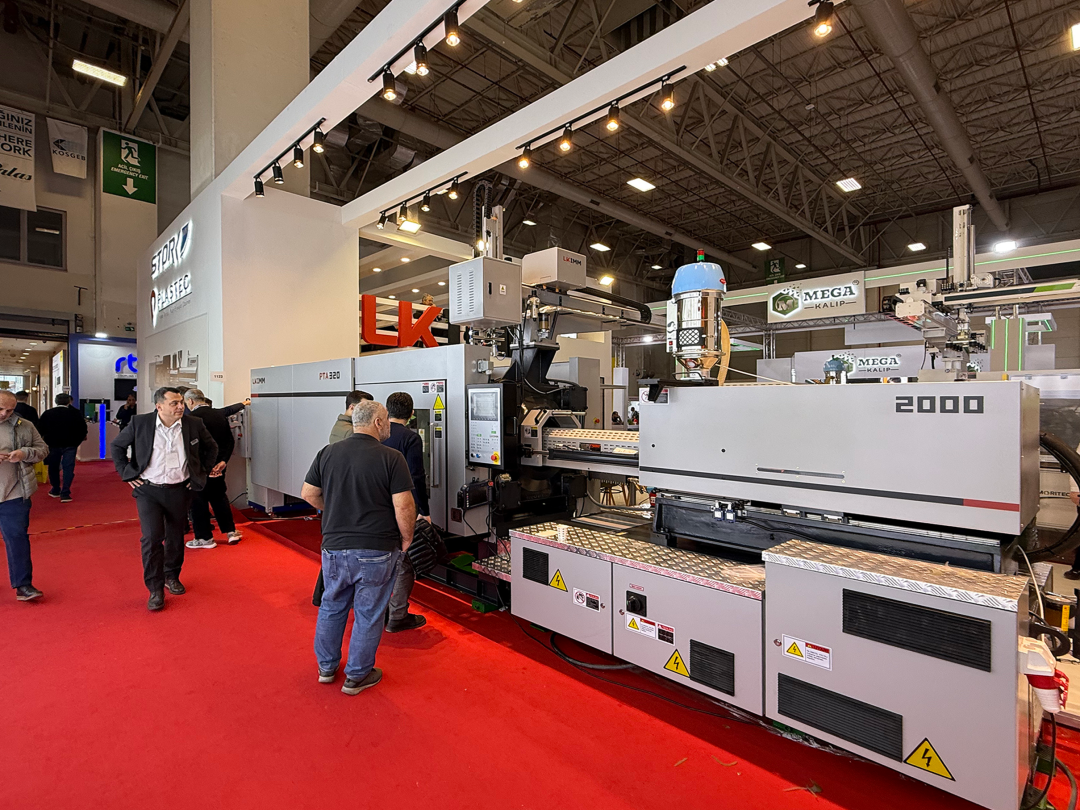

PTA320 Servo Energy-saving Injection Molding Machine

Based on the mature and reliable POTENZA series injection molding machines, a comprehensive upgrade has been made, covering the injection section, clamping structure, hydraulic system, and electrical control unit, among other software and hardware configurations. The plasticizing efficiency has been improved by 10%, the mold opening repeatability is ±0.5mm, and the product weight repeatability is 2‰.

All models come standard with CNC back pressure, upgraded injection carriage structure, comprehensive upgrade of screw plasticizing components, newly optimized lubrication system, in-depth optimization of platen structure, newly designed plasticizing barrel device, meeting the production needs and process requirements of different industries' products.

As the second largest plastic producer in Europe and the seventh largest in the world, Turkey serves as a springboard for companies entering the markets of Europe, the Middle East, North Africa, and Central Asia. Meanwhile, the plastic industry is one of the fastest-growing sectors among Turkey's emerging industries, with an annual production growth rate of 13.5%, giving it a significant competitive advantage in the global market.

Lijin Plastics Machinery has been deeply cultivating the Turkish market for many years, introducing more efficient, energy-saving, and environmentally friendly injection molding technologies to the region. The company promotes product customization and localized technical services, continuously supporting the development of the Turkish plastic industry and establishing a strategic foothold for in the Eurasian market.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

U.S. Appeals Court Officially Rules: Trump Tariff Unlawful and Void!

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory