Are Traditional Plastics Outdated? Toy Giants Are Optimistic About These New Materials~

Recently, following Lingna Belle and Bing Dwen Dwen, the 90s' childhood favorite Psyduck has also become a hit! Recently, KFC collaborated with Pokémon to create a Psyduck IP toy. The simple-to-play Psyduck music box quickly became the new favorite of young people through the fermentation on online platforms.

In fact, the cute and lovable Psyduck is made from LDPE material, which is a type of PE polyethylene. Apart from PE materials, ABS, PP, and PVC are also commonly used materials in children's toys. According to statistics, the application scale of PP polypropylene in the toy industry is the largest, at around 800,000 tons.

Recently, following Lingna Beier and Bing Dwen Dwen, the beloved Psyduck from the childhoods of many 90s kids has also become a hit! Recently, KFC collaborated with Pokémon to create a Psyduck IP toy. The simple-to-use Psyduck music box, through the fermentation on online platforms, quickly became the new favorite of young people.

In fact, the cute and adorable Psyduck is made of LDPE material, which is a type of PE polyethylene. Apart from PE materials, ABS, PP, and PVC are also commonly used materials in children's toys. According to statistics, the application scale of PP polypropylene in the toy industry is the largest, at around 800,000 tons.

Recently, following Linabell and Bing Dwen Dwen, the 90s' childhood favorite, Psyduck, has also become a hit! Recently, KFC collaborated with Pokémon to create a Psyduck IP toy. The simple-to-play Psyduck music box quickly became the new darling of young people through the fermentation on online platforms.

In fact, the cute and adorable Psyduck is made from LDPE material, which is a type of PE (polyethylene). Apart from PE materials, ABS, PP, and PVC are also commonly used materials in children's toys. According to statistics, the application scale of PP (polypropylene) in the toy industry is the largest, around 800,000 tons.

Recently, following Linabell and Bing Dwen Dwen, the 90s' childhood favorite, Psyduck, has also become a hit! Recently, KFC collaborated with Pokémon to create a Psyduck IP toy. The simple-to-play Psyduck music box quickly became the new darling of young people through the fermentation on online platforms.

Recently, following Linabell and Bing Dwen Dwen, the 90s' childhood favorite, Psyduck, has also become a hit! Recently, KFC collaborated with Pokémon to create a Psyduck IP toy. The simple-to-play Psyduck music box quickly became the new darling of young people through the fermentation on online platforms.

In fact, the cute and lovable Psyduck is made of LDPE material, which is a type of PE polyethylene. Apart from PE materials, ABS, PP, PVC, and other materials are also commonly used in children's toys. According to statistics, the application scale of PP polypropylene material in the toy industry is the largest, around 800,000 tons.

In fact, the cute and lovable Psyduck is made of LDPE material, which is a type of PE polyethylene. Apart from PE materials, ABS, PP, PVC, and other materials are also commonly used in children's toys. According to statistics, the application scale of PP polypropylene material in the toy industry is the largest, around 800,000 tons.

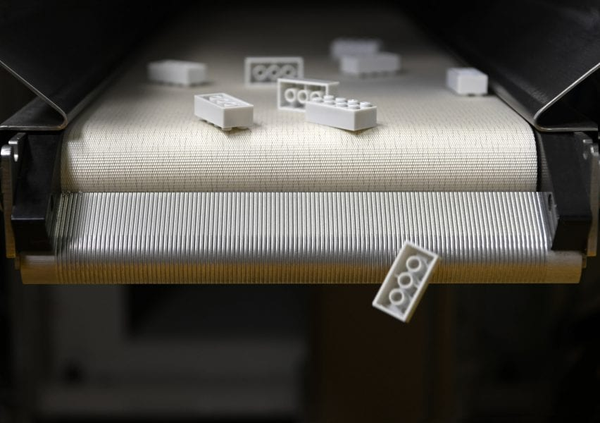

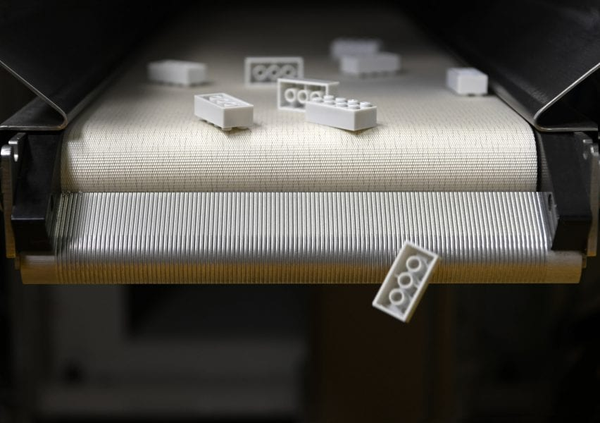

ABS is the primary material used for building block toys.

ABS is the primary material used for building block toys.

Polyvinyl chloride (PVC) can be both hard and soft. The animal models in toys that have a mix of soft and hard textures are made from PVC.

However, the potential safety threats posed by traditional plastics used in toys have been taken seriously by countries around the world. For instance, phthalate plasticizers, which were commonly used in toys and pose potential health risks to humans, have been severely restricted in many countries. China has also introduced a series of restrictive laws and regulations. Additionally, the introduction of dual carbon and sustainable development goals has put forward new requirements for material innovation in the toy industry.

Traditional toy manufacturers, such as Mattel, which owns the Barbie doll IP, and LEGO, which produces building blocks, have been criticized for using large amounts of plastic and have announced their commitment to using sustainable and safe materials. McDonald's has also announced that it will reduce the use of traditional plastics in its promotional toys by 90%. Recycled plastics and bio-based materials have become their best choices.

Now, let's take a look at the application of bio-based materials in toys!

▌Making toys with popcorn

Scientists at the University of Göttingen have long been researching sustainable and efficient processes for making products from popcorn kernels. These products have a wide range of uses: from packaging to insulation boards for building insulation. Now, the university has partnered with renowned German toy manufacturer Loick, which plans to use this technology in the future to produce toys, furniture, sports and fitness equipment, as well as children's car seats and headrests.

Loick has been producing sustainable toys under the PlayMais brand for over 20 years, previously using pure natural corn to make clay that is 100% biodegradable.

The license from the University of Göttingen will allow the company to expand its toy line in the future to include larger crafts based on compression-molded popcorn.

"This new process, based on technologies used in the plastics industry, can now be a cost-effective way to produce new sustainable children's toys or sports and fitness equipment, as well as furniture on an industrial scale," explains Professor Alireza Kharazipour, head of the Research Group for Composite Chemistry and Process Engineering at the University of Göttingen. "Especially for the furniture industry, this can ensure that alternative natural materials, beyond plastics, and even particle boards and fiberboards, are no longer just niche products."

"This new process, based on technology used in the plastics industry, can now be a cost-effective way to produce new sustainable children's toys or sports and fitness equipment, as well as furniture on an industrial scale," explains Professor Alireza Kharazipour, head of the Research Group for Composite Materials and Process Engineering at the University of Göttingen. "Especially for the furniture industry, this could ensure that alternative natural materials, besides plastics, even particle boards and fiberboards, are no longer just niche products."▌Mattel Group Barbie, bio-based PP material, recycled material

▌Mattel Group Barbie, bio-based PP material, recycled materialThe world's leading American toy company, Mattel, has chosen to collaborate with petrochemical giant SABIC to integrate certified renewable polymers into Mattel's products. The first toys made from certified renewable SABIC® PP (polypropylene) entered the market in 2022, with more to follow.

The world's leading American toy company, Mattel, has chosen to collaborate with petrochemical giant SABIC to integrate certified renewable polymers into Mattel's products. The first toys made from certified renewable SABIC® PP (polypropylene) entered the market in 2022, with more to follow.All Action Driver toy sets and Matchbox Recycling Trucks under the Matchbox brand include SABIC materials. Mattel's corporate goal is to have all Matchbox die-cast cars, toy sets, and packaging made of 100% recycled, renewable, and bio-based plastic materials by 2030.

All Action Driver toy sets and Matchbox Recycling Trucks under the Matchbox brand include SABIC materials. Mattel's corporate goal is to have all Matchbox die-cast cars, toy sets, and packaging made of 100% recycled, renewable, and bio-based plastic materials by 2030.

Sabic PP product general manager Lada Kurelec said: "The collaboration with Mattel is an important step in providing our customers with materials that help reduce the carbon footprint across a wide range of consumer markets, and Mattel is a pioneer in the toy industry." Previously, Mattel has also used recycled ocean plastics as the primary material for toys.

▌McDonald's to Reduce Traditional Plastics by 90% in Toys by 2025

From Snoopy and Power Rangers to Hot Wheels and Pokémon, McDonald's has long been bringing joy to children-friendly toys in its iconic Happy Meals. Now, Golden Arches is taking an earth-friendly step towards using sustainable materials to reduce plastic.

During the 2021 Climate Week, McDonald's announced its goal that by the end of 2025, every toy in every Happy Meal sold globally will be more sustainable, reducing traditional plastics by 90%, thereby lowering the demand for fossil fuel-based plastic production.

On August 13, 2021, McDonald's CEO Chris Kempczinski held a Happy Meal toy made from more sustainable materials in Chicago.

On August 13, 2021, McDonald's CEO Chris Kempczinski was seen in Chicago holding a Happy Meal toy made from more sustainable materials."The transition to making toys with more renewable, recycled, or certified materials will reduce the use of virgin fossil fuel-based plastic by about 90%, which is nearly equivalent to the population of Washington D.C., thus eliminating plastic from their lives in one year," McDonald's stated.

"The transition to making toys with more renewable, recycled, or certified materials will reduce the use of virgin fossil fuel-based plastic by about 90%, which is nearly equivalent to the population of Washington D.C., thus eliminating plastic from their lives in one year," McDonald's stated.▌Lego Toys Bio-Based PE, Recycled PET

▌Lego Toys Bio-Based PE, Recycled PETLego, founded by Ole Kirk Kristiansen in 1932, has become one of the world's leading toy brands, partly due to the durability of its iconic bricks. Since 1963, most of the billions of Lego bricks produced each year have been made from acrylonitrile butadiene styrene (ABS) plastic.

Lego, founded by Ole Kirk Kristiansen in 1932, has become one of the world's leading toy brands, partly due to the durability of its iconic bricks. Since 1963, most of the billions of Lego bricks produced each year have been made from acrylonitrile butadiene styrene (ABS) plastic.However, it has proven difficult for toy manufacturers to find a material as durable as traditional ABS blocks.

However, it has proven difficult for toy manufacturers to find a material as durable as traditional ABS blocks.

LEGO Group leader Brooks said: "We know that children care about the environment and want us to make our products more sustainable. Although it will still take some time before they can play with bricks made from recycled plastic, we want to let the children know that we are working hard and invite them to join us on this journey. Experimentation and failure are important parts of learning and innovation. Just like how children at home build, dismantle, and rebuild with LEGO bricks, we are doing the same thing in the lab."

LEGO Group leader Brooks said: "We know that children care about the environment and want us to make our products more sustainable. Although it will still take some time before they can play with bricks made from recycled plastic, we want to let the children know that we are working hard and invite them to join us on this journey. Experimentation and failure are important parts of learning and innovation. Just like how children at home build, dismantle, and rebuild with LEGO bricks, we are doing the same thing in the lab."But recently, LEGO announced that it will abandon virgin oil-based plastics by 2030. For this, LEGO is using PET as a material to replace ABS because PET has a higher recycling rate. On average, a 1-liter plastic PET bottle can provide enough raw material for ten 2 x 4 LEGO bricks. Currently, LEGO's patent-pending material formula enhances the durability of PET, making it sufficient for producing LEGO bricks. The innovative process uses custom composite technology to combine recycled PET with reinforcing additives.

But recently, LEGO announced that it will abandon virgin oil-based plastics by 2030. For this, LEGO is using PET as a material to replace ABS because PET has a higher recycling rate. On average, a 1-liter plastic PET bottle can provide enough raw material for ten 2 x 4 LEGO bricks. Currently, LEGO's patent-pending material formula enhances the durability of PET, making it sufficient for producing LEGO bricks. The innovative process uses custom composite technology to combine recycled PET with reinforcing additives.

In addition to recycled PET materials, in 2018, LEGO began producing toy parts made from bio-polyethylene (bio-PE) sourced from sustainably grown sugarcane. Bio-PE is very suitable for making smaller, softer components, such as trees, branches, leaves, and accessories for minifigures. Currently, bio-PE is not suitable for making harder, more robust parts, such as the iconic LEGO bricks.

LEGO elements made from plants

LEGO stated that, in addition to innovation in materials, it is also highly focused on sustainability in other areas. By 2022, the LEGO Group will invest up to $400 million over three years to accelerate the achievement of its sustainability goals.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.