CHINAPLAS 2025 | Green Choices for Innovative Applications of Polypropylene in Multiple Fields

Jingbo Polypropylene

In 2025, Jingbo will focus on high-performance polypropylene materials and the green environmental protection field, launching new products such as energy-saving foaming dedicated materials and cast film heat-seal layer dedicated materials. At the 2025 International Rubber and Plastics Exhibition, Jingbo's new series of polypropylene products will be showcased, covering multiple product series including medical-grade, food-grade, transparent impact-resistant, and more, with over 10 grades such as M800E and RP340R. The company offers a full range of transparent products with melt indices ranging from 8 to 60. Additionally, in specialized application scenarios, Jingbo has introduced several high-value polypropylene products, including transparent polypropylene (RP348P, HI340R), impact copolymer polypropylene, and expanded polypropylene (EPP800MM), providing greener options for customers in various industries such as daily chemical and home goods, high-end medical, automotive appliances, and food packaging.

Jingbo Polypropylene Four Major Series Solutions

Food Packaging Innovation

Containers made of grades such as M800E have the following features:

✓ -20℃~120℃ wide temperature range tolerance

✓ BPA-free, ensuring food safety

✓ Toughness-balanced impact-resistant structure

✓ High Transparency Aesthetic Presentation

Electronic product protection

EPP800MM foam special material innovative application:

Supercritical CO₂ Foaming Process (Zero Pollution)

✓ Better seismic buffering performance, lightweight and durable

Transparent polypropylene RP348P combines clinical safety, reliable sterilization, and environmental friendliness.

✓ Heat resistant and sterilizable, with high purity and sterilization adaptability

✓ High barrier properties (effectively block the permeation of oxygen, water vapor, grease, and other substances)

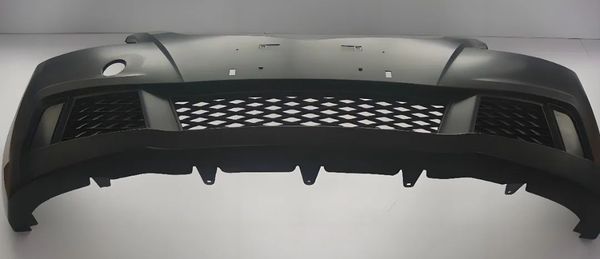

Optimization of Impact Copolymer Polypropylene Lightweight Materials:

✓ Good impact resistance

✓ Good liquidity, excellent processing performance

✓ Achievable production that is large and fast, with components that are large and lightweight.

Zang Yuntao, General Manager of JINGBO Polyolefins

Jingbo Polyolefins is committed to achieving efficient integration of shock absorption, lightweight design, and high physical strength. Our EP548R and K9930H are designed with high flowability and high impact strength to absorb collision energy. The bumper support layer absorbs and buffers energy, ensuring component stability in extreme environments ranging from -40°C to 80°C.

CHINAPLAS 2025 is coming soon.

CHINAPLAS

CHINAPLAS 2025 is coming soon.

Lock Shenzhen World Exhibition & Convention Center, Jingbo Hall 16 C41 booth

Exploring the endless possibilities of polypropylene materials!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Amcor Opens Advanced Coating Facility for Healthcare Packaging in Malaysia

-

ExxonMobil and Malpack Develop High-Performance Stretch Film with Signature Polymers

-

Plastic Pipe Maker Joins Lawsuit Challenging Trump Tariffs

-

Pont, Blue Ocean Closures make biobased closures work

-

Over 300 Employees Laid Off! Is Meina Unable to Cope?