CHINAPLAS 2025 International Plastics and Rubber Exhibition | Liensheng Precision Invites You to Join the Grand Event

CHINAPLAS 2025

The 37th China International Plastics Rubber Industry Exhibition

The 37th China International Plastics and Rubber Industry Exhibition (CHINAPLAS 2025) will be held at the Shenzhen World Exhibition & Convention Center from April 15 to 18, 2025. At this exhibition, Liansheng Precision will present intelligent and eco-friendly overall injection molding production solutions, showcasing Liansheng's approach to innovation and development in the industry. We warmly welcome friends and customers to visit and share in this grand event!

Booth number: Hall 12 R31

Exhibition Plan

Electric Precision Injection Molding Machine

Medical Consumables Production Solutions

The GE-LS120 all-electric precision injection molding machine, equipped with medical consumables precision molds and peripheral auxiliary equipment, showcases a complete set of forming solutions at the booth. The performance features of the GE series all-electric precision injection molding machine, including precision, stability, and efficiency, are prominently displayed.

Exhibited Model: GE-LS120 Fully Electric Precision Injection Molding Machine

1

The device has strong performance.

The GE series all-electric precision injection molding machine features a stable solid-state heating control system, with a temperature control accuracy of ±1℃ and a mechanical repeatability of ±0.01mm. The equipment operates with agility and smoothness, meeting the precision requirements of the products.

2

High-precision control system

Equipped with an excellent all-electric injection molding machine control system and high-response high-precision servo motors, it can accurately control the end point of injection. With precise injection pressure sensors forming a closed-loop control, the outstanding injection pressure loop control ensures the stability of the product.

3

High production efficiency

The all-electric injection molding machine shortens the molding cycle by 3 to 5 seconds compared to traditional hydraulic injection molding machines under the same production conditions. It can also achieve synchronous ejection and synchronous melting functions.

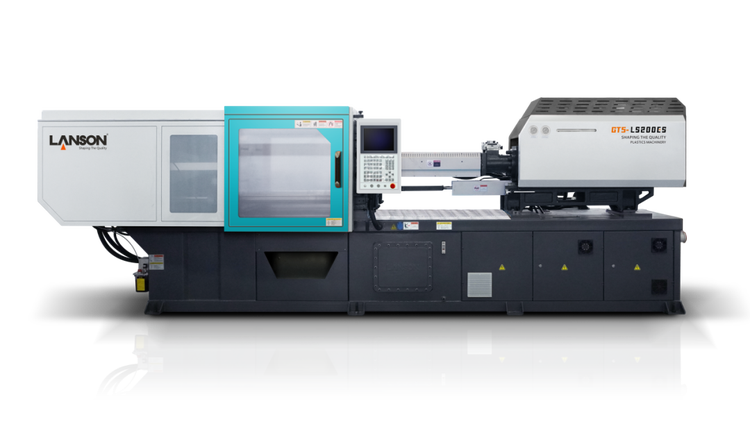

GT5 single-cylinder precision injection molding machine:

Special Application Scheme for Electric Melting Glue Injection Platform

This solution employs the Liansheng fifth-generation single-cylinder precision injection molding machine equipped with the ES series electric melt glue-specific injection unit. This injection unit is specifically developed for injection molding machines with a clamping force of 260 tons or below, compatible with Liansheng's GT3 and GT5 series models. It maintains the performance advantages of the single-cylinder structure while achieving energy efficiency and high productivity.

Exhibited Model: GT5-LS200ES Specialized Injection Unit Application Solution for Hot Melt Adhesive

Maintaining the performance advantages of the single-cylinder structure and injection parameters, increase the screw rotation speed by 11%.

Electric melting glue can save about 15% to 30% energy consumption in the melting process compared with traditional hydraulic motor melting glue.

It can achieve synchronous plasticizing function, shorten the plasticizing cycle, and improve production efficiency by more than 20%.

GT5-BT Thin-Wall High-Speed Injection Molding Machine:

Small bucket packaging production solution

The GT5-BT high-speed injection molding machine features a brand-new control system, combined with a dedicated servo drive system, ensuring smoother machine operation. To meet the requirements of thin-wall packaging molds, the rigidity of the clamping mechanism has been further enhanced.

In addition, it is equipped with a brand new launch platform structure, high-response servo motors, with a speed response of less than 25ms. The entire system is equipped with a dual power system, with a shooting speed of 350-450mm/s. It adopts a new pump control technology, achieving more precise control accuracy.

Exhibited Model: GT5-LS280BT High-Speed Injection Molding Machine

1

High rigidity frame

The framework is widened, the machine frame weight is increased, and the clamping system is strengthened, with an improvement of 15%-20% in strength, rigidity, and clamping force. The pressure piping uses flared steel pipes to avoid welding, making the layout more convenient for maintenance.

2

High-precision control system

The new shooting platform structure adopts a high-response servo motor paired with a dedicated servo drive system for control, achieving a speed response of less than 25ms, ensuring smoother operation.

Equipped with a dual power system across all models, firing rate of 350-450 mm/s. Utilizes new pump control technology for more precise control accuracy.

3

Equipped with direct-drive hot melt glue

After implementing the electric melting glue solution on the Liansheng Precision high-speed machine, the electricity consumption during the glue melting process is reduced by approximately 36% compared to using a hydraulic motor, achieving an overall machine energy saving of 12%. The electricity-saving effect is significant. The larger the product glue volume and the longer the melting time, the more pronounced the electricity-saving effect becomes.

A mold equipped with a needle valve can achieve simultaneous melt flow, which saves electricity and increases production efficiency, reducing the molding cycle by about 20%.

Booth Location

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."