Co-extruded film - Air column bag

1. Definition of Air Column Bags

Buffer air column bags, also known as inflatable bags or columnar inflatable bags, are a new type of packaging material in the 21st century that uses natural air for filling. The comprehensive, column-based cushioning protection minimizes product damage during transportation. These bags are made by laminating or co-extruding LLDPE and NYLON, offering tensile resistance and balanced characteristics. Through continuous pressure sealing, airtight inflatable columns are formed. The machine-produced protective film is called Air-Bag.

Utilizing physical principles, fully inflated in one go with automatic air-locking. In case of damage, only the individual air column is affected, while the remaining columns remain fully functional, maintaining protective effects. Offers long-term storage and transportation without air leakage, providing comprehensive cushioning protection with air columns, significantly reducing damage rates.

The air cushion bag is a new packaging system that utilizes air for cushioning, providing a snug wrap around the product to ensure its protection. Compared to traditional fillers, it prevents frequent shifting and damage during transportation due to large empty spaces inside the packaging box. Even when subjected to external pressure, the close-fitting design of the air cushion bag disperses the force through the air cushions to avoid damage.

2. Advantages of buffer air column bags

High-quality PE+PA film, sturdy and durable, with high airtightness, offers more reliable protection. The base material, tested by SGS, contains no heavy metals and is non-toxic when burned, meeting the characteristics of air impermeability and moisture resistance, making it a suitable alternative to polystyrene, EPE, and pulp.

The cost of cushion air column bags is very low, with production processes being fully mechanized and automated. The production efficiency of air column bags is high, and there is no need for mold creation, testing, or replacement, thus saving a significant amount of research and production costs.

Compared to traditional cushioning packaging, air column bags take up very little space before inflation, saving both space and effort. Importantly, consumers no longer have to deal with large amounts of cushioning packaging after receiving their goods.

4. Provides long-term shockproof protection during storage and transportation without air leakage, and automatically locks in air after inflation. Even if one air column is damaged, it will not affect the overall cushioning protection of the air column bag for the product.

5. Improve the corporate image. Air column bags, as a relatively advanced modern packaging material, can reduce a lot of resource waste. Therefore, using air column bags can greatly help enhance the corporate image and gain positive reviews from users.

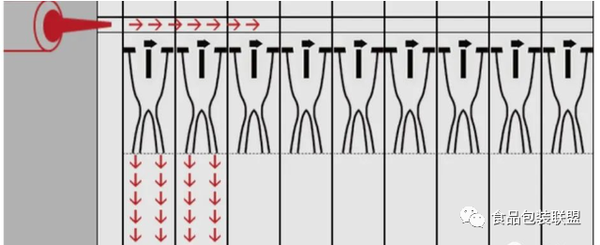

III. Basic Principles of Air Cushion Bags

Bubble wrap is a "magical" packaging material that does not need to be sealed, as gas can only enter or exit during the inflation process, due to the reverse air check valve film of the air column bag.

When manufacturing air column bags, two layers of reverse air valve films are used as the inner membrane. The function of these two layers of air valve films is to provide an air intake channel for each air column during the inflation process. Simultaneously, after the air pressure is applied, the reverse air check valve film tightly adheres to the outer membrane. Utilizing the bonding function provided by the pre-made heat-sealing points, the air circuit is tightly closed by the air pressure.

Air column bags have strong pressure resistance because the raw material of air column bags is nylon co-extruded film. Co-extruded film belongs to new material technology, which allows different materials to be co-extruded into the same film through multi-die co-extrusion technology. Nylon (PA) is located in the inner layer to provide super toughness and durability, while polyethylene (PE) has compressibility, providing heat-sealing properties.

Typically, the structure of the seven-layer nylon co-extruded film used for air column bags is PE-PE-TIE-PA-TIE-PE-PE. Each layer of the film provides different functions, and the different layers are combined into a single film. Air column bags can retain gas for an extended period, which is also enabled by the nylon co-extruded film. Nylon is a barrier material with strong gas retention properties, allowing air column bags to hold gas for up to six months.

IV. Application Range of Air Cushion Bags

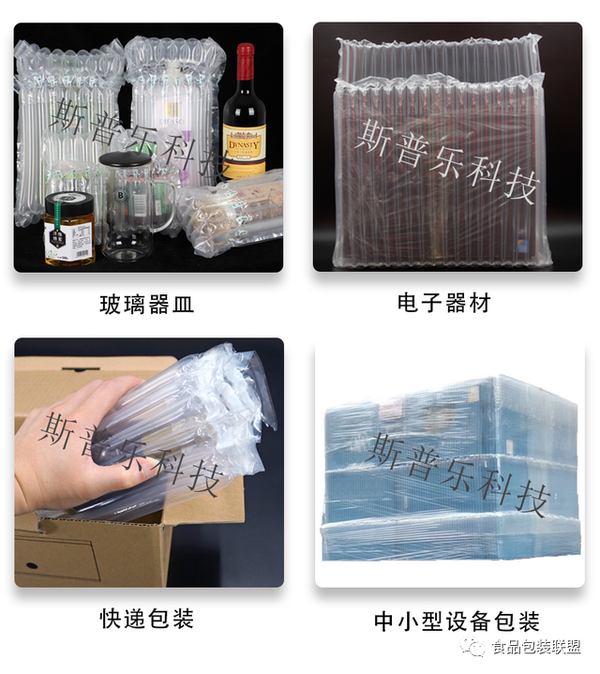

Electronics Packaging

Electronic products are related items that operate based on electrical energy, primarily including: watches, smartphones, telephones, televisions, video recorders, camcorders, radios, cassette players, stereo systems, CD players, computers, gaming consoles, mobile communication devices, and more.

02 Fragile Product Packaging

Fragile products made from materials such as glass, convex and concave mirrors, pottery, and porcelain have significant price variations. Using air column bags for cushioning during transportation can reduce losses.

03 Precision Instrument Packaging

For precision instruments or expensive products, such as pianos and medical equipment, accuracy is of utmost importance. Collisions and bumps can greatly affect their quality. The emergence of air column bags has significantly improved this situation, as the performance of the inflatable bags is pressure-resistant and impact-resistant.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.