At this year's Chinaplas International Rubber and Plastics Exhibition (April 15-18, 2025 | Shenzhen World Exhibition & Convention Center, Bao'an, China), Coperion will showcase core technologies for the entire process chain of plastics processing and recycling at booth K25 in Hall 10.

Coperion will showcase two extruders that are very suitable for the current challenges of plastic compounding and recycling. The fourth generation...STS 75 Mc PLUTwin-screw ExtruderIts 13.6 Nm/cm³ specific torque has increased the capacity of the STS extruder by 20%, and the product quality has also significantly improved. A productZSK 58 Mc18Twin-screw extruderThe equipment will also be exhibited at this event, featuring exceptional torque to meet high production demands, particularly suitable for products requiring high torque, such as engineering plastics. In addition, Coperion will highlight its reliable and high-precision feeding solutions, including a...Ktronic T35 Loss-in-Weight Feeder Pair with a replenishment unit for2415 Vacuum Feeder, as well as aCalmaThe C/S-LW-NS 60 single-screw feeder systemA machine.ProRate PLUS-M FeederCVH 550 High-Pressure Rotary Valveand one for granular materialsWEK 265 double-acting directional valve。

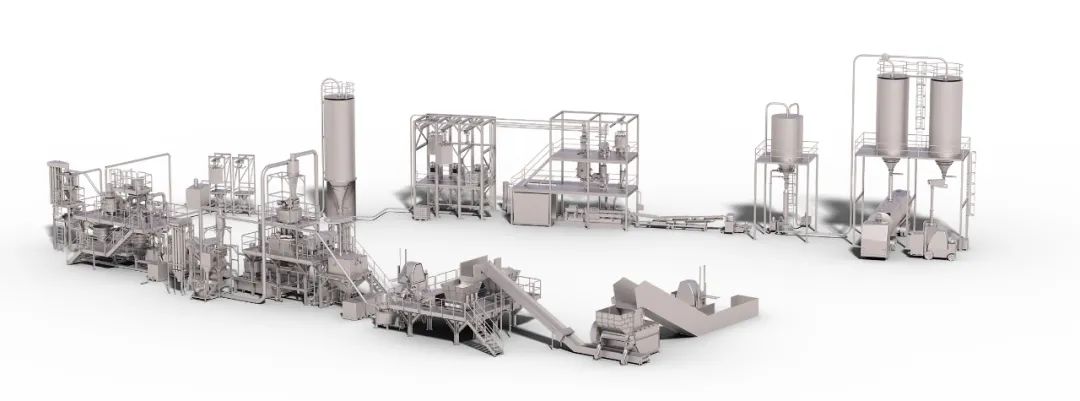

In the field of plastic recycling, Coperion andHerbold MeckesheimCollaborating to provide manufacturers with rich technical expertise and process solutions, we will showcase a virtual 3D recycling system at this international plasturgy exhibition. Visitors will have the opportunity to see the inner core components of the recycling system and observe the process technology details and efficient component processing at each step.

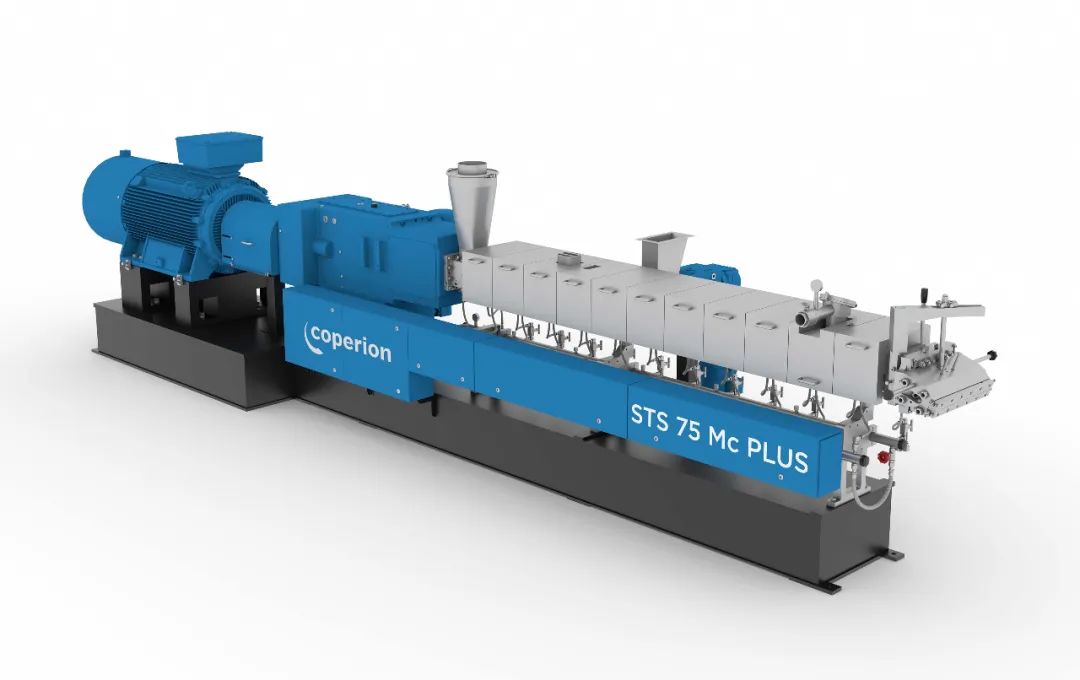

STS Mc PLUS extruder: An economical and efficient solution suitable for various applications.

Over the years, the STS extruder series has established itself in the market as a high-quality product for a variety of extrusion and compounding tasks, such as engineering plastics and masterbatches, as well as cable materials, recycling of regrind plastics, powder coatings, etc. This extruder is produced in Coperion Nanjing and meets CE standards as well as Coperion's high quality standards. They are known for their attractive price-to-performance ratio.

Coperion's 10K25 booth showcased the STS 75 Mc PLUS, which represents the fourth generation of STS technology, achieving a screw speed of 900 min.-1At that time, its specific torque can reach 13.6 Nm/cm³. This improvement enables mixing manufacturers to deliver higher quality products, and compared to earlier models, each application can increase production capacity by 20%. The key to achieving this performance level and technological improvements lies in optimizing the core components of the drive segment. This STS 75 Mc PLUS extruder is equipped with a more powerful motor and a transmission designed specifically for its high torque. The core shaft uses high-performance materials to ensure sufficient torque output from the transmission to the processing section. The high fill level in the processing section is crucial for the STS 75 Mc PLUS to achieve excellent mixing quality. It simultaneously reduces shear stress and lowers the melting temperature while improving mixing performance. The result is high output with very gentle material handling. This will also be...KalmykC/S-LW-NT38 twin-screw feederExhibited together.

The torque of the Coperion STS 75 Mc PLUS twin-screw extruder has been increased to 13.6 Nm/cm³, boosting production capacity by 20% while also enhancing product quality.。

The torque of the Coperion STS 75 Mc PLUS twin-screw extruder has been increased to 13.6 Nm/cm³, boosting production capacity by 20% while also enhancing product quality.。

ZSK Mc18Extruder: Manufactured for Higher Demands

Visitors can also learn more about the advantages of the well-known ZSK series extruders. These high-performance extruders, such as the exhibited ZSK 58 Mc¹⁸, achieve high output and great economic benefits. This extruder with a specific torque of 18 Nm/cm³ is characterized by consistent high output and top-notch product quality. By assembling in China, Coperion can respond to customer needs as quickly as possible. Customers can enjoy local value-added services, reduce transportation and tax costs, and shorter delivery times. This time, it will be paired withK-ML-SFS-KT20 twin screw feeder by Coperion K-TronExhibit.

A complete system for recycling plastic from a single source

KraussMaffei and Herbold Meckesheim have jointly realized a plant for various plastic recycling applications, demonstrating excellence in reliability and high product quality. From mechanical processing - shredding, washing, separation, drying, and pelletizing of plastics - to bulk material handling, feeding, and extrusion, to compounding and granulation, the entire process chain of recycled plastics is covered. At the same time, KraussMaffei and Herbold Meckesheim provide solutions for various recycling processes such as mechanical recycling of industrial and post-consumer waste, chemical recycling, PET recycling, or solvent recycling.

Especially for the recycling of post-consumer waste (PCR) or any highly contaminated polymers, Coperion offers the innovative ZSK FilCo filter compounding extruder, which can perform filtration and compounding in a single production step. Compared to the two-step production line that has been used to date, Coperion's ZSK FilCo is known for its more streamlined equipment configuration. Energy consumption and emissions in the compounding process have been reduced by more than 50%.

The reliability of plastic recycling equipment from Coperion and Herbold Meckesheim is outstanding, and the quality of the recycled products is very high.

Powerful, flexible and accurate feeding solution: ProRate PLUS

ProRate PLUSThe feeder integrates cutting-edge European feeding technology and control systems, ensuring high precision and reliability during the loss-in-weight feeding process. This production line meets the growing demand in the plastics industry for robust and efficient feeding solutions.ProRate PLUSThe continuous weighing feeder production line is an economical solution that can quickly yield a return on investment due to its cost-effectiveness and rapid delivery.

The ProRate PLUS feeder line features a space-saving trapezoidal design, allowing up to six feeders to easily group around the extruder feed throat within a 1.5-meter [5-foot] radius. Three single-screw feeder models—PLUS-S, PLUS-M, and PLUS-L—along with the PLUS-MT twin-screw model, cover a wide range of throughput requirements and bulk materials. Depending on the material, the ProRate PLUS feeder can handle feeding rates from 3.3 to 4800 dm.3/h[0.12 to 400 ft3 /h]. Theoretically, a feeding system equipped with six ProRate PLUS-L feeders can achieve up to 28.8 m on a footprint of just 7 square meters [75 square feet].3/h[1017 ft3Feeding capacity of /h].

The ProRate PLUS feeder features a space-saving trapezoidal design, allowing up to six feeders to be easily grouped around the extruder's feed port within a 1.5-meter [5-foot] radius.

Intelligent Feeding Solution

In addition, at this year's international rubber and plastic exhibition, Coperion will also highlight the high precision of Coperion K-TronK2-ML-D5-T35Feeding machine, equipped with intelligent material vibration fluidizer.ActiFlow™Pressure Compensation System(EPC)To demonstrate its professional skills in all feeding tasks, the feeder is also equipped with a 2415 vacuum loader for material replenishment.

ActiFlow™ Intelligent Material Vibrating Fluidizer is a revolutionary design that, for materials with poor flowability, especially sticky materials, eliminates the need for stainless steel.

The mixer used inside the steel material hopper can effectively prevent the formation of arching and rat holes. This intelligent fluidizer applies slight vibrations to the hopper walls, carefully providing fluidization power to the materials inside the hopper with an ideal amplitude and frequency, automatically adjusted by the controller based on the material flow. It is specifically designed for the Schenck Process loss-in-weight feeder.

Comprehensive worry-free service

Coperion has conducted intensive research and development work for the construction of new plants and the integration of existing systems. To this end, Coperion offers comprehensive maintenance and upgrade packages for all its products and technologies, significantly enhancing the productivity, flexibility, and reliability of the equipment. This service allows equipment operators to fully exploit the potential functions of the equipment in a short time.

Kebron (www.coperion.com) The above content is already in English. It seems there might have been a misunderstanding. The provided sentence "****************" is in Chinese and translates to English as:

"It is a compounding and extrusion system."Crushing, cleaning, sorting, drying, and pelletizing system solutionsOne of the global industry and technology leaders in feeding and metering systems, material and pneumatic conveying systems, as well as grinding, mixing, heat treatment, dust removal, and other services. KABELON researches, manufactures, and maintains systems, equipment, and components for the plastics and plastic recycling industry, as well as for the chemical, battery, mining, food, and pharmaceutical industries. In the three major divisions of performance materials, food, health and nutrition, and aftermarket sales and services, KABELON has5,000Name of employee and50A sales and service company. Coperion isHillenbrand(New York Stock Exchange code:HIThe operating company of **.HillenbrandIt is a global industrial company that provides highly integrated core process processing equipment and solutions for customers in various industries around the world. www.hillenbrand.com

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

The torque of the Coperion STS 75 Mc PLUS twin-screw extruder has been increased to 13.6 Nm/cm³, boosting production capacity by 20% while also enhancing product quality.。

The torque of the Coperion STS 75 Mc PLUS twin-screw extruder has been increased to 13.6 Nm/cm³, boosting production capacity by 20% while also enhancing product quality.。