Drone light shows dazzle the night sky, and it's surprising to see that light-diffusing PC and light diffusers have such applications on drones.

Light show drones are a new type of equipment that performs light shows through drone technology, which has been widely used in performances, parties, and other occasions in recent years. The light strips/light covers are their key components, requiring materials to be high-strength, heat-resistant, and have good light diffusion effects.

light diffusion PC

In this type of application, light-diffusing PC material is usually chosen as the lampshade. This is a modified plastic that is translucent but not transparent, made from a base of transparent polycarbonate plastic, with the addition of light diffusers and other additives, and processed through special modification techniques. The light source's rays undergo multiple refractions, reflections, and scattering within the light-diffusing PC light strip/lampshade, transforming point light sources into soft, uniform surface light sources, avoiding strong hotspots and glare, and providing a comfortable visual effect.

The strength of light-diffusing PC material is relatively high, with good impact resistance. Even when subjected to a certain degree of external force collision, it is not easy to break. This can ensure that during the installation and use of the light strip/light cover, the material will not be damaged due to accidental collisions, thereby extending the service life of the light strip.

Light diffusing PC material has good weather resistance, whether it is high temperature, low temperature, humidity, or ultraviolet radiation, etc., it is not easy to cause problems such as material aging, discoloration, and embrittlement. When the drone flies outdoors for a long time, the lampshade/light strip always maintains good optical and mechanical properties.

light diffuser

Light diffusing plastic essentially aims to increase the material's haze while maintaining high light transmittance, finding a balance between the two.

The main approach currently being developed is to add light diffusers, which are essentially highly spherical microspheres close to nanosize that can transmit visible light and also scatter it.

Light diffusers can be added to transparent resins such as PC, PVC, PS, PMMA, PET, epoxy resins, and LEDs (light-emitting diodes) to increase light scattering and transmission. While blocking the glaring point light source, it can also make the entire resin emit a softer, more beautiful, and elegant light, achieving a comfortable effect of light transmission without transparency.

working principle

Organic light diffusers are synthesized using polymerization technology through means such as cross-linking and grafting functional groups to produce microspheres with uniform particle size distribution, of which silicone is one category.

The light diffusion principle of organic light diffusers is: light passes through the surface of organic light diffuser particles, utilizing the refractive index difference between the organic light diffuser and the base resin, producing light refraction to achieve the effect of light diffusion, i.e., uniform light.

Compared to inorganic light diffusers that only provide uniform light without enhancing transmission, organic nano-microbead light diffusers allow light to pass through, effectively solving the issues of uniform light and light transmission, with silicone-based organic light diffusers showing even more pronounced effects.

light diffuser selection

different light diffuser compound selection

Different light diffuser compound selections can achieve cross refraction, greatly increasing the haze. The reason is that multi-component light diffusers have different refractive indices, but the light transmittance is not as high as that of a single component formula.

(2) Different light diffusers are selected for different substrates

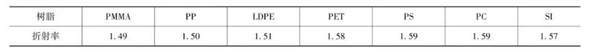

It is required to maintain a certain difference in refractive index between the light diffuser and the base material resin to ensure sufficient light refraction; however, the difference in refractive index cannot be too large, as this would cause total reflection, greatly affecting transparency. Therefore, different light diffusers are chosen for different base materials.

(3) particle size distribution of light diffusing agent

The light diffuser is spherical in shape, with a particle size distribution in the range of 2 to 4 μm. The uniformity of its particle size has a significant impact on the light diffusion effect; the narrower the particle size distribution, the better the light diffusion effect.

The impact of light diffusers on resin performance

optical performance

The transmittance of resin with added light diffuser will decrease, and it is required that the impact of the light diffuser on transmittance be as small as possible. A good light diffuser should result in a small decrease in transmittance when added to the resin, while significantly increasing the haze.

mechanical properties

Compared to inorganic light diffusers, which can lead to a decrease in impact strength and tensile strength, organic light diffusers have less effect on the mechanical properties of resins and may even improve them to varying degrees.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.