Featuring excellent bulkiness, soft touch, and elasticity, Toray will launch an eco-friendly, high-value-added acrylic staple fiber.

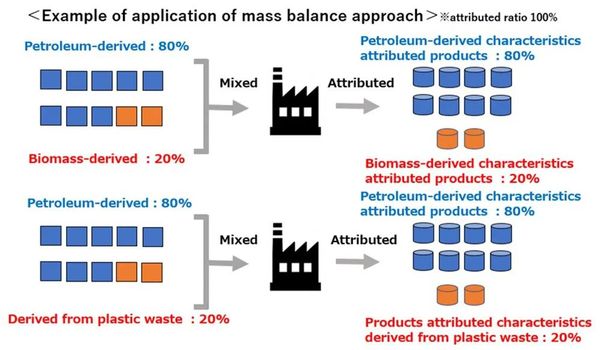

March 12 - Toray Industries, Inc. announced that it will start producing Toray acrylic staple fibers using the mass balance method from this April. This method is attributed to characteristics from biomass and plastic waste. The company has obtained ISCC (International Sustainability and Carbon Certification) PLUS certification for the product.

Toray's fiber and textile business strategy focuses on expanding growth areas through the development of high-value-added, high-performance products that use environmentally friendly materials. Therefore, the company uses both recycled materials and biomaterials, especially nylon and polyester fibers. Acrylic fibers have been a challenge in this regard due to the lack of waste resources for this single material. The mass balance approach will enable Toray to offer high-value-added TORAYLON with environmental consciousness.

TORAYLON has excellent bulkiness, colorability, compatibility with other fibers, soft hand feel, and elasticity, making it very suitable for a wide range of applications, including sweaters, socks, sportswear, and other garments, as well as blankets, mats, and curtains. It is increasingly being used in products that require the following functions: anti-pilling, thermal insulation, moisture absorption, water resistance, stain resistance, and anti-static.

The company will work with supply chain partners to advance life cycle assessment (life cycle assessment is a method for evaluating the environmental impacts associated with all stages of a product or service's life) verification, and apply for inclusion in the Higg Index (the Higg Index is a self-assessment tool launched by the Sustainable Apparel Coalition, now known as Cascale, in 2012, aimed at assessing sustainable product development and supply chain management, focusing on environmental and social responsibility. This benchmark helps highlight environmental impacts and labor rights issues, encouraging companies to make their products and supply chains more sustainable. The global apparel and fashion industry uses this tool).

According to Toray Group's sustainability vision, the company has set achieving a world of sustainably managed resources as one of its 2050 goals. It is making company-wide efforts to address issues such as resource depletion, marine pollution caused by plastic waste, and carbon dioxide emissions through the development of various technologies. These technologies include recycling of discarded plastic products and processing waste, use of bio-based materials, and utilization of renewable energy. Toray Group also adopts a mass balance approach to promote the use of recycled resources and bio-based materials.

Toray will continue to pursue R&D to realize a sustainable recycling-based society as part of its ongoing efforts to achieve its corporate philosophy of "contributing to society by creating new value through innovative ideas, technologies, and products."

Acrylic, also known as polyacrylonitrile fiber. Acrylic is a synthetic fiber made from a copolymer with acrylonitrile as the main monomer, and its molecular chain contains at least 85% (by mass) of acrylonitrile repeating units. It usually appears white (can also be dyed in other colors), curly, fluffy, soft to the touch, very similar to wool, and has better warmth retention than wool, hence it is known as "synthetic wool." Acrylic has a relatively low density, good chemical stability (resistant to acids, weak alkalis, oxidants, and general organic solvents), excellent light resistance, heat resistance, weather resistance, and anti-mildew and anti-moth properties. Acrylic is typically available in three specifications: acrylic tow, acrylic staple, and acrylic sliver.

Main uses: Acrylic is generally spun into yarn through cotton or wool spinning, and is mainly used in clothing (such as hats, gloves, scarves, faux fur, sweaters, knit sportswear), decoration (such as carpets, curtains), blankets, plush toys, and outdoor (such as covers for cars and boats) and other fields.

I. Clothing Field

everyday clothing

①Used for making sweaters, knitwear, sportswear, scarves, gloves, hats, etc. Acrylic bulky yarn can be processed into fluffy and soft fabrics, suitable for winter warm clothing (such as mountaineering clothes, overcoats);

② Imitation wool products. Acrylic can be used for pure spinning or blended with wool to make yarn, blankets, and artificial fur, replacing natural wool to reduce costs;

③Special purposes. The clothing has excellent light and weather resistance, suitable for outdoor wear (such as covers for vehicles and boats, swimwear) and children's clothing.

2, home decor

Used for carpets, curtains, bedding, sofa covers, etc., due to its wear resistance, light resistance, and ease of dyeing, it can maintain bright colors for a long time;

②For toys and decorations. Plush toys, cushion fillings, etc., utilizing their fluffy and soft characteristics.

II. Industrial Applications

Industrial materials. As filtering materials (acid and alkali resistant), insulating materials, filling materials, etc., suitable for chemical, automotive, and other fields;

②Special fiber products. Polyacrylonitrile-based carbon fiber precursor (to be excluded from the taxation scope) used for producing high-strength carbon fibers, applied in high-tech industries such as aerospace.

III. Expanded Applications of Modified Acrylic Fiber

① Imitation cashmere fabric, fine denier acrylic or imitation cashmere acrylic, has a hand feel similar to natural cashmere, suitable for high-end light and thin clothing;

②Simulated animal fur with irregular cross-section acrylic (such as flat shape) can mimic animal fur, used for fashion outerwear or decorations.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Amcor Opens Advanced Coating Facility for Healthcare Packaging in Malaysia

-

ExxonMobil and Malpack Develop High-Performance Stretch Film with Signature Polymers

-

Plastic Pipe Maker Joins Lawsuit Challenging Trump Tariffs

-

Pont, Blue Ocean Closures make biobased closures work

-

Over 300 Employees Laid Off! Is Meina Unable to Cope?