Gore-Tex responds to PFAS in rain jackets! Reputable organizations and companies: The entire industry is gradually phasing it out.

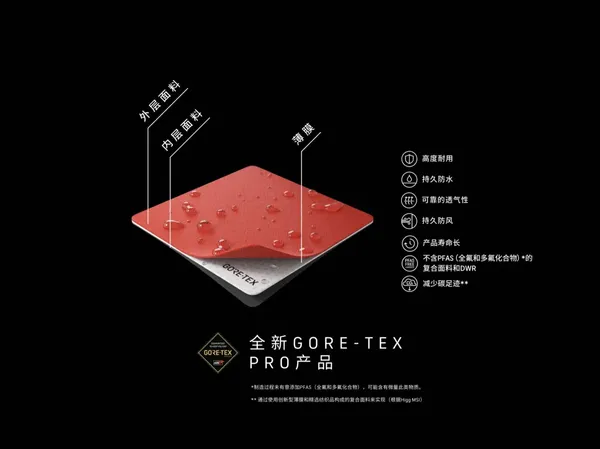

GORE-TEX fabric, a high-tech material invented by the international fabric giant W. L. Gore & Associates in 1969, can block liquid water while allowing water vapor to pass through. It offers durable waterproofing, windproofing, and breathability, overcoming the common defect of waterproof fabrics that lack breathability. As a result, it is hailed as the "Fabric of the Century." Known as the "King of Outdoor Fabrics," GORE-TEX's exceptional waterproofing primarily relies on PFAS. While GORE-TEX's waterproof technology has revolutionized the outdoor sports experience, it has also contributed to the silent infiltration of "forever chemicals"—PFAS (per- and polyfluoroalkyl substances)—into the environment and human bodies.

On March 26, the report "Wearing Once Pollutes Once? Many Outdoor Jackets Contain This Harmful Substance, Famous Mountaineers Have Already Abandoned It, and Leading Companies Are Starting to Use Alternative Fabrics" was released, drawing consumer attention to outdoor apparel brands' use and disclosure of per- and polyfluoroalkyl substances (PFAS).

As "forever chemicals," PFAS can accumulate in the human body and the environment, causing negative health and environmental impacts. Currently, the states of California and New York in the U.S. have enacted legislation banning the sale of PFAS-containing clothing from 2025.

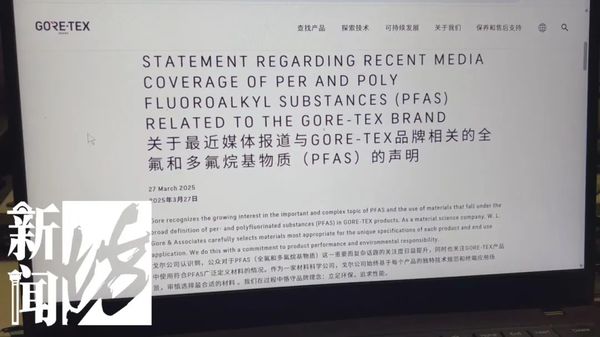

As the core of this incident, the "GORE-TEX" brand, whose parent company is W. L. Gore & Associates, responded swiftly. On U.S. local time on the 27th, the company issued an official statement, recognizing the increasing public concern over PFAS. The company always carefully selects the most suitable materials, prioritizing environmental protection while pursuing performance.

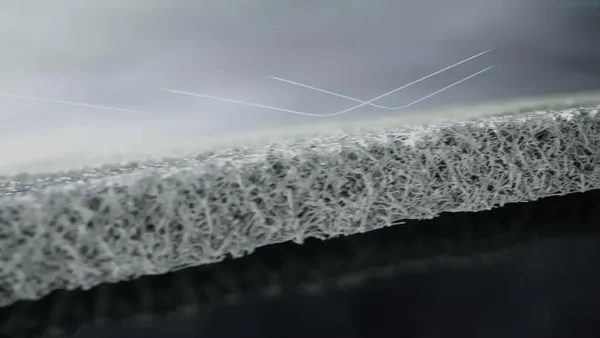

Gore also stated that the GORE-TEX brand launched the ePE film in 2022, which is made from expanded polyethylene and does not intentionally add PFAS. By the end of 2025, most of the company's consumer fabric products will utilize Gore ePE film technology.

Recently, regarding the focal topics of "the progress in the development of PFAS alternative materials" and "the urgent need for full industry collaboration," spokesperson Gin Ando from the leading outdoor brand Patagonia and Inga Bleyer, the market and communications director of the certification body OEKO-TEX, were interviewed by reporters from *The Economic Daily*. The OEKO-TEX certification is adopted by thousands of brands and manufacturers worldwide, and its certification label serves as an important reference for consumers purchasing safe and eco-friendly products.

Balancing functionality and environmental protection is difficult.

But many companies are actively trying.

NBD: Has the textile industry found a completely替代PFAS waterproof breathable materials? If not, what are the main technological bottlenecks?

Inge Bair: Currently, there are some alternatives that can provide a similar level of water resistance, but no alternative can provide all the performance attributes of PFAS. This is especially true in the field of personal protective equipment (PPE), where phase-out is happening slowly. It's worth noting that personal protective equipment is generally exempted in most regulations.

NBD: What is the main function of PFAS in Patagonia outdoor clothing? How important are these functions to the consumer's outdoor experience?

Gene Anzeng: In Patagonia (the product), PFAS are primarily used for waterproofing. Because we design this type of product for some of the harshest environments on Earth, our clothing must perform exceptionally well and ensure user safety. Having fully functional clothing outdoors can increase the enjoyment of experiencing nature in any environment.

NBD: What progress has the company made in developing PFAS alternatives? Can these alternative materials match or exceed the performance of PFAS in terms of water resistance and other critical properties?

Gene Anderson: Since we became aware of the significant hazards associated with the production process of PFAS, we have been engaged in a decade-long research and testing effort to develop PFAS alternatives. The reason it has taken so long is that we insist the performance of the alternatives must not be inferior to that of PFAS-containing garments. After testing hundreds of fabrics and chemical formulations, we have now achieved complete elimination of deliberately added PFAS in even our professional products designed for extreme environments. None of our current full product line or future seasonal releases will contain deliberately added PFAS substances.

NBD: What is the current overall usage of PFAS in the textile industry?

Inga Blair: Textile manufacturers are becoming more aware of the impacts of PFAS, leading to a decline in the use of these chemicals in recent years. As far as we know, many brands are actively phasing out PFAS in their products.

NBD: What technical and supply chain challenges does Patagonia face in reducing or eliminating the use of PFAS? How are these challenges being addressed?

Gene Ando: In the first batch of PFAS-free fabric samples we received, some were so stiff that they could be torn in half like cardboard. We discovered early in the R&D process that removing PFAS affects far more than just water resistance—two key indicators, the fabric's tear resistance and seam slippage, change due to the alternatives, and we must innovate to address these issues.

In some cases, we simply remove PFAS treatment because it is not necessary at all; whereas in some of our windproof jacket lines, we have adopted waterproof and breathable technologies specifically designed for automotive batteries. We have invested substantial time and resources into research to ensure that the durability and functionality of the garments are not compromised by these eco-friendly innovations.

"We are all partners in the same boat when it comes to environmental protection."

NBD: Is the current international detection standard and certification system for PFAS in textiles完善? Are institutions planning to introduce stricter detection standards and certification systems?

Inga Becker: Since 2023, we have completely banned the intentional use (presence) of PFAS substances in products certified by "OEKO-TEX STANDARD 100", products certified by the Leather Standard, and chemicals certified by "ECO PASSPORT". Currently, we use the total fluorine limit value as the testing standard, which complies with current U.S. regulations and aligns with the upcoming EU regulatory standards. Additionally, we have recently improved our PFAS detection methods to enhance testing accuracy. The new method can detect not only easily releasable PFAS but also PFAS bound to the substrate.

NBD: As a leader in environmental responsibility in the industry, how does Patagonia view the efforts of the outdoor clothing sector in reducing the use of PFAS? Will the company collaborate with other brands or organizations to drive the industry towards a PFAS-free future?

Gene Ando: We are very willing to help the industry make progress together. In terms of environmental protection, we are all partners on the same boat.

NBD: Given that various countries and regions around the world are gradually legislating to regulate PFAS, will Patagonia's eco-friendly clothing updates be implemented逐步实施 based on local policies, or will there be a one-time global replacement and upgrade? The sentence seems to be cut off at the end. Assuming it continues with "逐步实施" (implemented step by step), the complete translation would be: NBD: Given that various countries and regions around the world are gradually legislating to regulate PFAS, will Patagonia's eco-friendly clothing updates be implemented step by step based on local policies, or will there be a one-time global replacement and upgrade?

Gene Ando: All of our new products no longer have added PFAS. Even if US law changes to allow them again, we know the harm they cause and won't go back. It took us a full decade to find good quality alternatives, and the industry is gradually phasing them out anyway.

NBD: Based on OEKO-TEX's observations in the textile industry, what do you think are the core challenges the industry currently faces in terms of sustainable development? What specific suggestions do you have for promoting collaboration across all links in the industry chain to achieve environmental goals?

Inga Blair: We believe that the focus in the future will be more on transparency and traceability. Transparency and traceability are key to identifying and addressing challenges within their respective supply chains and gaining a broader understanding of economic, ecological, and social sustainability. We believe that legislative bodies will also demand greater transparency and traceability in the future.

Over the course of our 30-year development, we have established strong partnerships with all sectors of the textile and leather industries. We recommend that all industry participants strengthen cooperation, jointly explore issues and needs, and work together to find solutions.

● Has a high specific strength (i.e., strength-to-weight ratio), allowing it to be made into lightweight, thin, and structurally robust composite materials.

● Has outstanding durability, which can further reduce environmental impact.

● Combined with polyurethane (PU) to form a durable waterproof, windproof, and highly breathable film.

The Higg MSI measurement results indicate that expanded polyethylene (ePE) materials and lighter film weights can reduce carbon footprints.

● Aligns with the GORE-TEX Textiles Division goal: to not use PFCECs, which are PFCs (perfluorinated compounds) that impact the environment, throughout the lifecycle of its mass-market products, achieved here by using non-fluorinated materials.

Products using the new GORE-TEX ePE membrane will be applied in many products from brands such as Adidas, ARC'TERYX, Dakine, Patagonia, Reusch, Salomon, or Ziener.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.