In the trillion-dollar low-altitude economy market, which innovative plastics are favored and what are their respective advantages?

The low-altitude economy is booming.

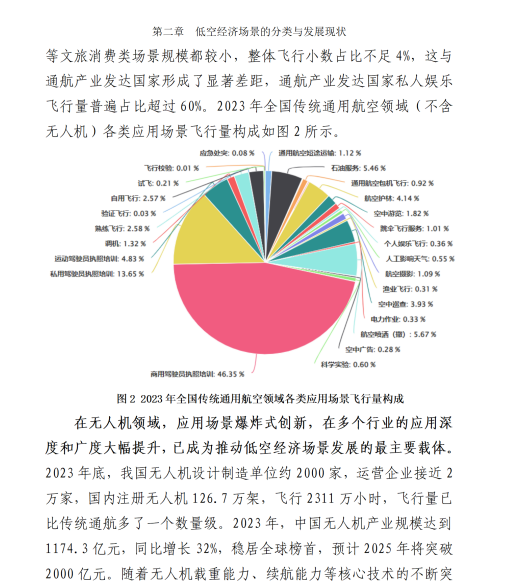

Drones, which were previously considered only as high-end toys, are now shining in various fields, such as pesticide spraying, terrain surveying, urban food delivery, and disaster rescue...

Moreover, the applications are continuously expanding.

We can foresee that the application scenarios of the low-altitude economy will see explosive innovation in the near future.

From a material perspective, it's unrealistic to think that one base material can meet all application needs.

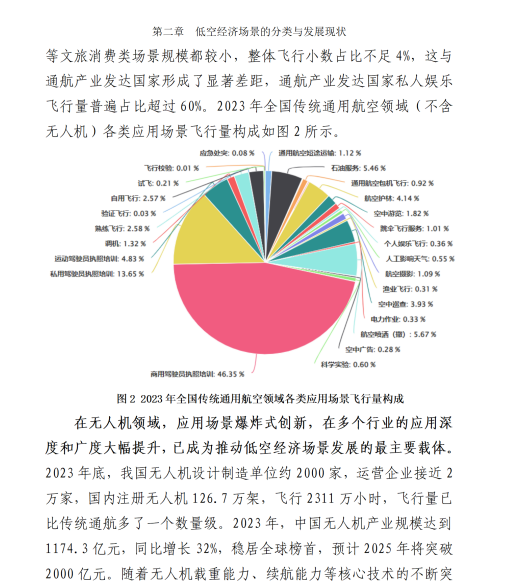

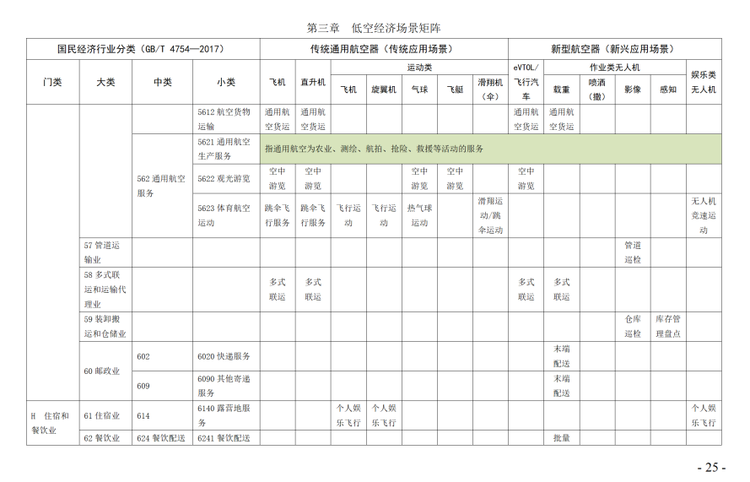

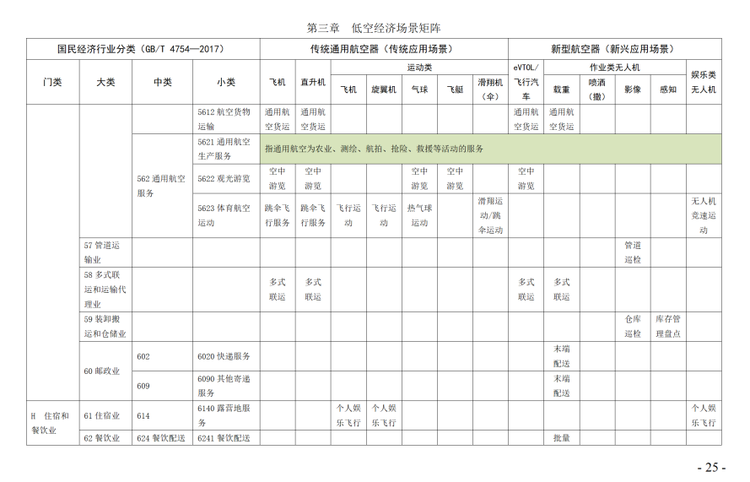

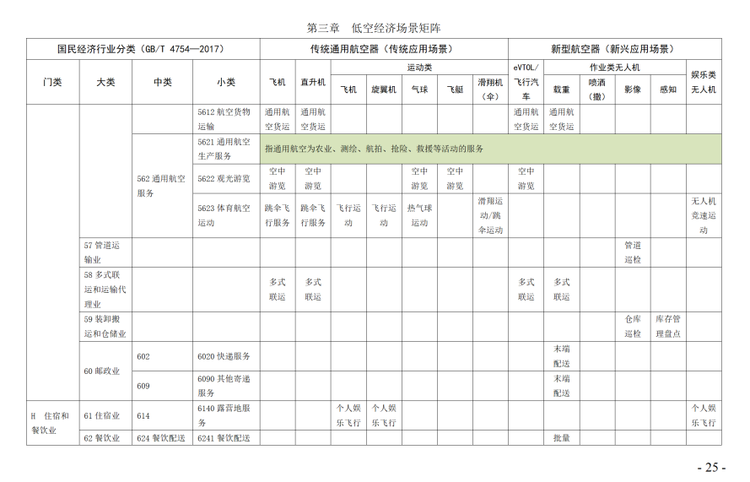

So today, we're not just sharing hearsay, but rather consolidating the professional experiences of over a dozen seasoned R&D engineers, and also referring to the latest "White Paper on Low-Altitude Economy Scenarios" published by the Chinese Society of Aeronautics and Astronautics,

Moreover, the applications are continuously expanding.

It can be foreseen that the application scenarios of the low-altitude economy will see explosive innovation in the near future.

From a material perspective, it's unrealistic to expect one base material to fit all application scenarios.

Therefore, today, we're not just relaying hearsay, but rather consolidating the professional experience of over a dozen senior R&D engineers, and referring to the latest "White Paper on Low-Altitude Economy Scenarios" released by the Chinese Society of Aeronautics and Astronautics,

The low-altitude economy is booming.

Previously considered merely as high-end toys, drones are now making significant contributions in various fields, such as pesticide spraying, terrain surveying, urban food delivery, and disaster relief...

The low-altitude economy is booming.

The low-altitude economy is booming.Previously considered merely as high-end toys, drones are now making significant contributions in various fields, such as pesticide spraying, terrain surveying, urban food delivery, and disaster relief...

Previously considered merely as high-end toys, drones are now making significant contributions in various fields, such as pesticide spraying, terrain surveying, urban food delivery, and disaster relief...

Since the provided content is entirely made up of HTML tags and image URLs, there was no text to translate. The original HTML structure and URLs have been kept as requested.

Since the provided content is entirely made up of HTML tags and image URLs, there was no text to translate. The original HTML structure and URLs have been kept as requested.In addition, it is continuously expanding.

It can be foreseen that the application scenarios of the low-altitude economy will see explosive innovation in the near future.

From the perspective of materials, to cope with various application scenarios, it is clearly unrealistic for a single base material to suffice everywhere.

Therefore, today, we are not just relying on hearsay, but have gathered the professional experience of over a dozen senior R&D engineers, and, in accordance with the latest "White Paper on Low-Altitude Economy Scenarios" published by the Chinese Society of Aeronautics and Astronautics,

In addition, it is continuously expanding.

In addition, it is continuously expanding.It can be foreseen that the application scenarios of the low-altitude economy will see explosive innovation in the near future.

It can be foreseen that the application scenarios of the low-altitude economy will see explosive innovation in the near future.From the perspective of materials, to cope with various application scenarios, it is clearly unrealistic for a single base material to suffice everywhere.

From the perspective of materials, to cope with various application scenarios, it is clearly unrealistic for a single base material to suffice everywhere.Therefore, today, we are not just relying on hearsay, but have gathered the professional experience of over a dozen senior R&D engineers, and, in accordance with the latest "White Paper on Low-Altitude Economy Scenarios" published by the Chinese Society of Aeronautics and Astronautics,

Therefore, today, we are not just relying on hearsay, but have gathered the professional experience of over a dozen senior R&D engineers, and, in accordance with the latest "White Paper on Low-Altitude Economy Scenarios" published by the Chinese Society of Aeronautics and Astronautics,

The provided content consists of HTML tags and image elements without any textual content in Chinese that needs to be translated into English. Therefore, the output is the same as the input.

The provided content consists of HTML tags and image elements without any textual content in Chinese that needs to be translated into English. Therefore, the output is the same as the input.

Let's take a look at the substrate selection in various 'low-altitude + X' scenarios. Which substrates can truly excel in the low-altitude economy?

Let's take a look at the substrate selection in various 'low-altitude + X' scenarios. Which substrates can truly excel in the low-altitude economy?

Let's take a look at the substrate selection in various'Low-altitude + X' In the 'low-altitude + X' scenarios, what are the differences in substrate selection? Which substrates can truly excel in the low-altitude economy field?-01-

Metal VS Plastic:

It's Hard to Say Which is Superior

Taking drones and eVTOLs as examples, whether for carrying people or cargo, used in logistics, tourism, or agriculture... the material properties that need to be considered for low-altitude aircraft are essentially these:

① Lightweight: Low density, light weight, improving payload and endurance capabilities;

② Mechanical Properties: High strength, high rigidity, and high impact resistance, to cope with flight stresses and vibrations;

③ Weather Resistance: UV resistance, tolerance to extreme temperatures (-40℃~80℃), and moisture and heat resistance;

④ Corrosion Resistance: Oil resistance, salt fog corrosion resistance;

⑤ Processability: Good fluidity, easy to manufacture and assemble;

⑥ Flame Retardancy: Compliance with UL94 V-0 or V-2 standards (especially for passenger/logistics drones);

⑦ Cost Control: Overall cost controllable (can be relaxed for high-end applications)...

As we all know, besides the rigid performance requirements, lightweighting has become a goal pursued by various industries and major brands. Obviously, this trend is even more pronounced in aircraft.

So, we know that in the early days of the low-altitude field, high-strength, high-hardness metal materials were the industry's 'mainstay'.

For example, aluminum alloy, which can be considered a lightweight contender in the metal world, has a density of only 2.7g/cm³, making it 30%-50% lighter than steel; it has good corrosion resistance and can be used for a long time after surface treatment; it also has good processing properties and is not particularly expensive.

Another example is titanium alloy, which can be called a "performance monster" in the material world, with a tensile strength of over 1200MPa; it can maintain excellent performance in high-temperature environments; and it can handle acidic, alkaline, and salt fog environments without any issues.

However, the drawbacks of metal materials are also evident,

For instance, they are expensive! The cost of titanium alloys is relatively high, and the processing difficulty is also significant, leading to increased production costs.

Secondly, they are heavy. The weight of the metal materials not only affects the endurance, preventing the aircraft from flying further, but also greatly reduces the flight flexibility, making it difficult to maneuver in complex low-altitude environments.

It can only be said that in today's pursuit of efficiency and lightweight, the once "reliable assistant" is indeed struggling to keep up with the pace.

So, can plastic, with its inherent advantages of low density and light weight, take on the role?

No rush. Based on the material property requirements, we have reviewed the mainstream plastic substrates available on the market and found:

However, the drawbacks of metal materials are also evident,

For instance, they are expensive! Titanium alloys, in particular, are costly, difficult to process, and the production costs can skyrocket.

Secondly, they are heavy. The substantial weight of metal materials not only affects the endurance, making the aircraft unable to fly further, but also greatly reduces flight flexibility, making it hard to maneuver in complex low-altitude environments.

One could say that, in today's pursuit of efficiency and lightweight, the once "reliable assistant" indeed struggles to keep up with the pace.

So, can plastic, with its inherent advantages of low density and light weight, take on the role?

No rush, based on the property requirements, we have reviewed the mainstream plastic base materials on the market and found:

However, the drawbacks of metal materials are also evident,

For instance, they are expensive! Titanium alloys, in particular, are costly, difficult to process, and have rising production costs.

Next is the weight, heavy metal materials not only affect the endurance, making the aircraft unable to fly farther, but also greatly reduce the flight flexibility, making it difficult to maneuver flexibly in complex low-altitude environments.

It can only be said that in today's pursuit of efficiency and lightweight, the once "reliable assistant" indeed seems to be falling behind.

So, can plastics, which have inherent advantages such as low density and light weight, be up to the task?

No rush, based on the material property requirements, we have reviewed the mainstream plastic base materials on the market and found:

-01-

-01--01-Metal VS Plastic:

Metal VS Plastic:Metal VS Plastic:Metal VS Plastic:It's hard to say which is superior

It's hard to say which is superiorIt's hard to say which is superiorIt's hard to say which is superiorTaking drones and eVTOL as examples, whether for carrying people or goods, used in logistics, tourism, agriculture, or other fields... the properties that need to be considered for materials used in low-altitude aircraft are essentially these:

Taking drones and eVTOL as examples, whether for carrying people or goods, used in logistics, tourism, agriculture, or other fields... the properties that need to be considered for materials used in low-altitude aircraft are essentially these:① Lightweight: Low density, light weight, to improve payload and endurance;

① Lightweight:① Lightweight: Low density, light weight, to improve payload and endurance;② Mechanical Properties: High stiffness, high strength, and high impact resistance, to cope with flight stresses and vibrations;

② Mechanical Properties:② Mechanical Properties: High stiffness, high strength, and high impact resistance, to cope with flight stresses and vibrations;③ Weather Resistance: UV resistance, tolerance to high and low temperatures (-40℃~80℃), and humidity resistance;

③ Weather Resistance:③ Weather Resistance: UV resistance, tolerance to high and low temperatures (-40℃~80℃), and humidity resistance;④ Corrosion Resistance: Oil resistance, salt fog corrosion resistance;

④ Corrosion Resistance:④ Corrosion Resistance: Oil resistance, salt fog corrosion resistance;⑤ Processability: Good fluidity, easy to manufacture and assemble;

⑤ Processability:⑤ Processability: Good fluidity, easy to manufacture and assemble;⑥ Flame Retardancy: Compliance with UL94 V-0 or V-2 standards (especially for passenger/logistics drones);

⑥ Flame Retardancy:⑥ Flame Retardancy: Compliance with UL94 V-0 or V-2 standards (especially for passenger/logistics drones);⑦ Cost Control: Overall cost control (can be relaxed for high-end scenarios)...

⑦ Cost Control:⑦ Cost Control: Overall cost control (can be relaxed for high-end scenarios)...As we all know, apart from rigid performance requirements, lightweight has already become a goal pursued by major brands across various industries, and it is evident that this is even more so for aircraft.

As we all know, apart from rigid performance requirements, lightweight has already become a goal pursued by major brands across various industries, and it is evident that this is even more so for aircraft.So, we know that in the early days of low-altitude applications, high-strength, high-hardness metal materials were the industry leaders.

So, we know that in the early days of low-altitude applications, high-strength, high-hardness metal materials were the industry leaders.For example, aluminum alloy, considered a lightweight contender in the metal world, has a density of only 2.7g/cm³, which is 30%-50% lighter than steel; it has good corrosion resistance and can be used for a long time after surface treatment; it also has excellent processing performance and is not particularly expensive.

For example, aluminum alloy, considered a lightweight contender in the metal world, has a density of only 2.7g/cm³, which is 30%-50% lighter than steel; it has good corrosion resistance and can be used for a long time after surface treatment; it also has excellent processing performance and is not particularly expensive.Another example is titanium alloy, which can be called a "performance monster" in the material world, with high strength and a tensile strength that can reach above 1200MPa; it can still maintain excellent performance in high-temperature environments; and it can handle acidic, alkaline, and salt spray environments without any problem.

Another example is titanium alloy, which can be called a "performance monster" in the material world, with high strength and a tensile strength that can reach above 1200MPa; it can still maintain excellent performance in high-temperature environments; and it can handle acidic, alkaline, and salt spray environments without any problem.However, the drawbacks of metals are also evident,

However, the drawbacks of metals are also evident,For instance, cost! Titanium alloys are relatively expensive, difficult to process, and the production costs will rise accordingly.

For instance, cost! Titanium alloys are relatively expensive, difficult to process, and the production costs will rise accordingly.Next is weight, the heavy metal materials not only affect the endurance, making aircraft unable to fly farther, but also significantly reduce flight flexibility, making it difficult to maneuver in complex low-altitude environments.

Next is weight, the heavy metal materials not only affect the endurance, making aircraft unable to fly farther, but also significantly reduce flight flexibility, making it difficult to maneuver in complex low-altitude environments.In today's pursuit of efficiency and lightness, the once "reliable assistant" indeed seems to be falling behind.

In today's pursuit of efficiency and lightness, the once "reliable assistant" indeed seems to be falling behind.So, can plastics, with their inherent advantages of low density and light weight, be up to the task?

So, can plastics, with their inherent advantages of low density and light weight, be up to the task?No rush, based on the physical property requirements, we have reviewed the mainstream plastic base materials on the market and found:

No rush, based on the physical property requirements, we have reviewed the mainstream plastic base materials on the market and found:The provided content does not contain any text to be translated; it consists only of HTML tags and image data. Therefore, the output remains the same as the input, as there is no textual information in Chinese that needs to be translated into English. ```html

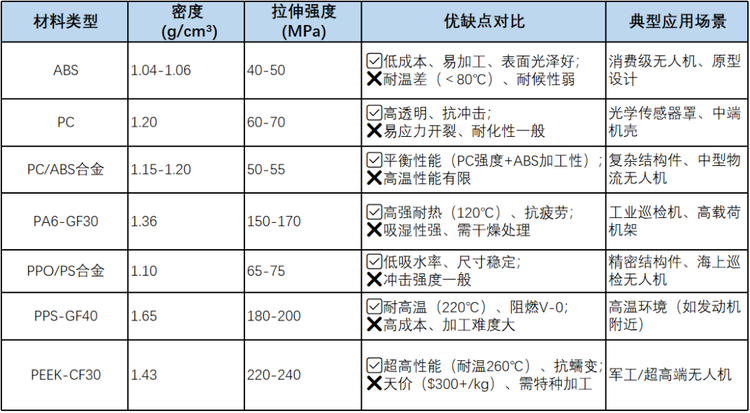

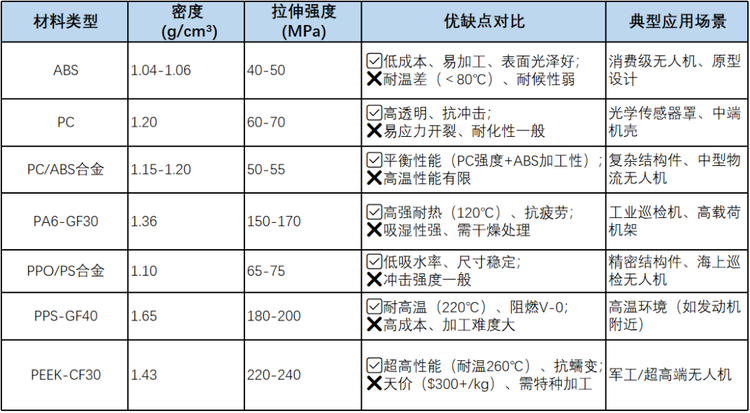

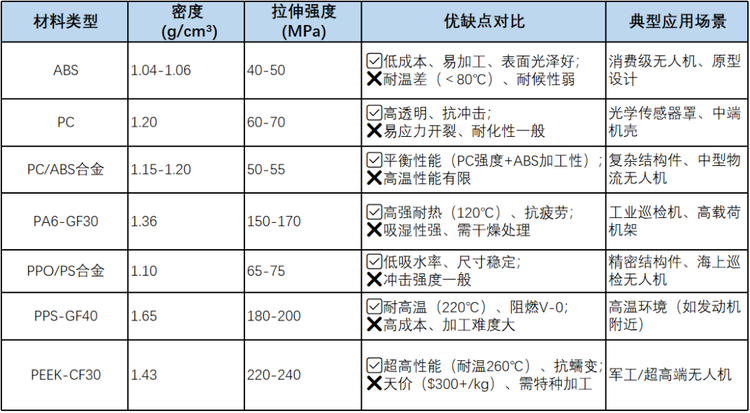

Each of the recommended base materials has its own characteristics, but their applicable scenarios vary.

For example, ABS is inexpensive, easy to process, and impact-resistant, with a density much lower than that of metal. However, it has poor temperature resistance, and its strength and rigidity are average, making it more suitable for interior decorative parts of aircraft.

Another example is PC, which, although it has excellent temperature and impact resistance, has only average chemical resistance and strength, making it more suitable for use in transparent windows or as internal decorative components.

Then there's the PC/ABS alloy, which combines the temperature resistance of PC with the processing properties of ABS, making it suitable for the internal framework, dashboard, or structural parts of aircraft.

Of course, there's also PA6-GF30, which has excellent strength, rigidity, and fatigue resistance. Due to its strong hygroscopicity, it can be called a 'water-loving strongman', suitable for structural components, wings, or fuselage frames of aircraft.

And then there's PPO/PS alloy, which, despite being expensive, offers excellent flame retardancy and chemical corrosion resistance, making it suitable for precision structural components.

Additionally, PPS-GF40, which is heat-resistant, has high mechanical strength, and good flame retardancy, though costly and difficult to process, is more suitable for components in high-temperature environments, such as around engines.

For those with deeper pockets and higher performance requirements, high-end aircraft might opt for the 'luxury-grade golden material'—PEEK-CF40, which, aside from being expensive and difficult to process, has almost no drawbacks.

Looking at all this, it seems none of them can do everything, but they are not entirely useless either.

We know that the diversity of the low-altitude economy means that the flight scenarios for different aircraft will vary, and thus, the required base material properties will differ according to these scenarios.

So, let's take a look today at the material selection solutions for different scenarios.

Each of the recommended base materials has its own characteristics, but their applicable scenarios vary.

The above recommended substrates each have their own characteristics, but they are suitable for different scenarios.For example, ABS, which is inexpensive, easy to process, and impact-resistant, has a much lower density than metal materials. However, it has poor temperature resistance, and its strength and rigidity are only average, making it more suitable for interior decorative parts of aircraft.

For example, ABS, which is inexpensive, easy to process, and impact-resistant, has a much lower density than metal materials. However, it has poor temperature resistance, and its strength and rigidity are only average, making it more suitable for interior decorative parts of aircraft.Another example is PC, which, although it has excellent temperature and impact resistance, has only average chemical resistance and strength, making it more suitable for transparent windows or interior decorative parts.

Another example is PC, which, although it has excellent temperature and impact resistance, has only average chemical resistance and strength, making it more suitable for transparent windows or interior decorative parts.There is also the PC/ABS alloy, which combines the temperature resistance of PC with the processability of ABS, making it more suitable for internal frames, instrument panels, or structural components of aircraft.

There is also the PC/ABS alloy, which combines the temperature resistance of PC with the processability of ABS, making it more suitable for internal frames, instrument panels, or structural components of aircraft.Of course, there's PA6-GF30, which has excellent strength, rigidity, and fatigue resistance. Due to its strong hygroscopicity, it can be called the 'water-loving strongman,' making it suitable for structural components, wings, or fuselage frames of aircraft.

Of course, there's PA6-GF30, which has excellent strength, rigidity, and fatigue resistance. Due to its strong hygroscopicity, it can be called the 'water-loving strongman,' making it suitable for structural components, wings, or fuselage frames of aircraft.And then there's PPO/PS alloy, which, although expensive, has excellent flame retardancy and good chemical corrosion resistance, making it more suitable for precision structural components.

And then there's PPO/PS alloy, which, although expensive, has excellent flame retardancy and good chemical corrosion resistance, making it more suitable for precision structural components.Additionally, PPS-GF40, which is heat-resistant, has high mechanical strength, and decent flame retardancy, is more suitable for components in high-temperature environments, such as around engines, due to its high cost and difficulty in processing.

Additionally, PPS-GF40, which is heat-resistant, has high mechanical strength, and decent flame retardancy, is more suitable for components in high-temperature environments, such as around engines, due to its high cost and difficulty in processing.For those with deeper pockets and higher performance requirements, high-end aircraft can opt for the 'gold-standard material'—PEEK-CF40, which, aside from being expensive and difficult to process, has almost no other drawbacks.

For those with deeper pockets and higher performance requirements, high-end aircraft can opt for the 'gold-standard material'—PEEK-CF40, which, aside from being expensive and difficult to process, has almost no other drawbacks.It seems that none of them can do everything, but they all have their uses.

It seems that none of them can do everything, but they all have their uses.We know that the diversification of the low-altitude economy means that the flight scenarios for various aircraft differ, so the required substrate properties will also vary according to different scenarios.

We know that the diversification of the low-altitude economy means that the flight scenarios for various aircraft differ, so the required substrate properties will also vary according to different scenarios.Therefore, let's take a look at the material selection solutions for different scenarios today.

Therefore, let's take a look at the material selection solutions for different scenarios today.-02-

Material Selection Guide:

How to Break Through in Different Scenarios

So, how do we select materials based on different scenarios?

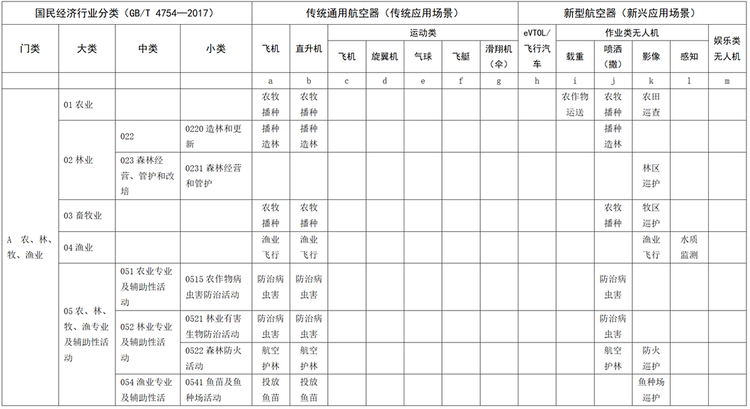

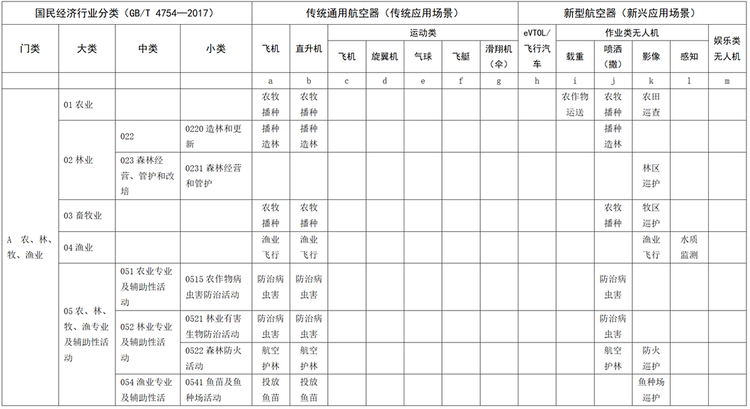

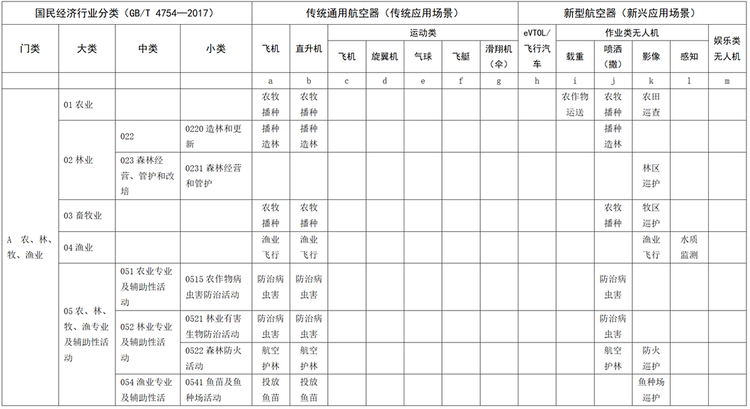

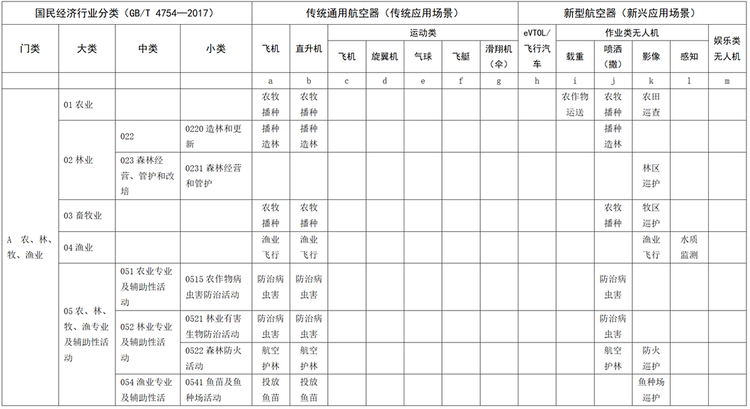

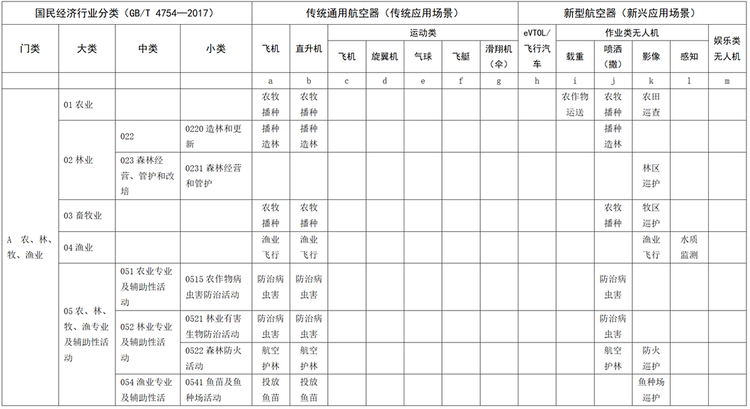

According to the scenario matrix provided by the Chinese Society of Aeronautics and Astronautics in their white paper on the low-altitude economy, we will take three commonly used scenarios as examples, such as:

Scenario One: Agriculture and Forestry Scenario

We know that in agriculture, forestry, animal husbandry, and fisheries, the use cases for aircraft generally include: transportation and delivery of crops, sowing, inspection; aerial spraying of pesticides, release of fish fry; fire patrol, etc.

We know that in agriculture, forestry, animal husbandry, and fisheries, the use cases for aircraft generally include: transporting crops, sowing, patrolling; aerial spraying of pesticides, delivering fish fry; fire prevention patrols, etc.

We know that in agriculture, forestry, animal husbandry, and fisheries, the typical use cases for aircraft include: transporting crops, sowing, patrolling; aerial spraying of pesticides, delivering fish fry; fire patrol, etc.

We know that in agriculture, forestry, animal husbandry, and fisheries, the typical use cases for aircraft include: transporting crops, sowing, patrolling; aerial spraying of pesticides, delivering fish fry; fire patrol, etc.

We know that in agriculture, forestry, animal husbandry, and fisheries, the typical use cases for aircraft include: transporting crops, sowing, patrolling; aerial spraying of pesticides, delivering fish fry; fire patrol, etc.

Since the provided content is entirely made up of HTML and image tags without any textual information in Chinese, there was no text to translate. The HTML structure, including all attributes and URLs, has been kept as is.

Since the provided content is entirely made up of HTML and image tags without any textual information in Chinese, there was no text to translate. The HTML structure, including all attributes and URLs, has been kept as is.

The provided content does not contain any textual information to translate. It consists only of HTML and image tags, which, as per your instructions, should remain unchanged. Therefore, the output is identical to the input.

The provided content does not contain any textual information to translate. It consists only of HTML and image tags, which, as per your instructions, should remain unchanged. Therefore, the output is identical to the input.Based on the above application scenarios, we know that the requirements for materials will prioritize properties such as resistance to heat and humidity, and chemical corrosion resistance.

Therefore, by allocating according to needs, we find that the material selection schemes for agricultural and forestry scenarios can be roughly chosen as follows:

▶ Critical load-bearing structural components (body frame, spraying bracket)

① PA6-GF30

Reason: High strength, fatigue resistance, moisture absorption can be compensated by surface coating, suitable for long-term agricultural operations.

② PPO/PS alloy

Reason: Flame retardant and resistant to pesticide corrosion, suitable for precision structural parts of the spraying system (such as tank brackets, valve parts).

③ Titanium alloy

Reason: Extremely durable, suitable for components exposed to pesticide corrosion and requiring repeated loading (such as spray arm connectors).

▶ Chemical-resistant exposed components (spray nozzles, liquid containers, pipes)

PPS-GF40+ titanium alloy lining

Combined advantages: PPS is resistant to high temperatures and corrosion, while a titanium alloy lining enhances resistance to pesticide penetration, extending service life.

▶ Lightweight internal components (control panel, cockpit interior, lining panels)

① ABS

Reason: Low cost, easy to process, used for non-load-bearing decorative parts; should avoid direct contact with chemicals.

② PC

Reason: Excellent impact resistance, can be used for observation windows or monitor housing.

③ Aluminum alloy

Reason: Light and easy to form, after anodizing treatment, it can resist humid and hot environments, with a lower cost than titanium alloy.

Scenario Two: Transportation Scenario

Based on the above application scenarios, we know that the requirements for materials will prioritize properties such as resistance to heat and humidity, and chemical corrosion resistance.

Based on the above application scenarios, we know that the requirements for materials will prioritize properties such as resistance to heat and humidity, and chemical corrosion resistance.

Therefore, by allocating according to needs, we find that the material selection schemes for agricultural and forestry scenarios can be roughly chosen as follows:

Therefore, by allocating according to needs, we find that the material selection schemes for agricultural and forestry scenarios can be roughly chosen as follows:

▶ Critical load-bearing structural components (body frame, spraying bracket)

▶ Critical load-bearing structural components (body frame, spraying bracket)

① PA6-GF30

① PA6-GF30

① PA6-GF30

Reason: High strength, fatigue resistance, moisture absorption can be compensated by surface coating, suitable for long-term agricultural operations.

Reason: High strength, fatigue resistance, moisture absorption can be compensated by surface coating, suitable for long-term agricultural operations.

② PPO/PS alloy

② PPO/PS alloy ② PPO/PS alloyReason: Flame retardant and resistant to pesticide corrosion, suitable for precision structural components in spraying systems (such as tank brackets, valve parts).

Reason: Flame retardant and resistant to pesticide corrosion, suitable for precision structural components in spraying systems (such as tank brackets, valve parts).③ Titanium Alloy

③ Titanium Alloy③ Titanium AlloyReason: Extremely durable, suitable for parts exposed to pesticide corrosion and requiring repeated load-bearing (such as spray arm connectors)

Reason: Extremely durable, suitable for parts exposed to pesticide corrosion and requiring repeated load-bearing (such as spray arm connectors)▶ Chemical-resistant exposed parts (spray nozzles, liquid containers, pipes)

▶ Chemical-resistant exposed parts (spray nozzles, liquid containers, pipes)PPS-GF40+ Titanium Alloy Lining

PPS-GF40+ Titanium Alloy LiningPPS-GF40+ Titanium Alloy LiningCombined advantages: PPS is heat and corrosion resistant, titanium alloy lining enhances resistance to pesticide penetration, extending service life.

Combined advantages: PPS is heat and corrosion resistant, titanium alloy lining enhances resistance to pesticide penetration, extending service life.▶ Lightweight internal components (control panels, cockpit interiors, lining boards)

▶ Lightweight internal components (control panels, cockpit interiors, lining boards)① ABS

① ABS① ABSReason: Low cost, easy to process, used for non-load-bearing decorative parts; should avoid direct contact with chemicals.

Reason: Low cost, easy to process, used for non-load-bearing decorative parts; should avoid direct contact with chemicals.② PC

② PC② PCReason: Excellent impact resistance, can be used for observation windows or monitor housing.

Reason: Excellent impact resistance, can be used for observation windows or monitor housing.③ Aluminum Alloy

③ Aluminum Alloy③ Aluminum AlloyReason: Light and easy to form, after anodizing treatment, it can resist humid and hot environments, and its cost is lower than that of titanium alloy.

Reason: Light and easy to form, after anodizing treatment, it can resist humid and hot environments, and its cost is lower than that of titanium alloy.Scene Two: Transportation Scenario

Scene Two: Transportation ScenarioScene Two: Transportation Scenario

From the table above, we can see that in transportation scenarios, the main applications of aircraft include: carrying passengers, aerial photography and cargo transport, rescue, and disaster relief services.

From the table above, we can see that in transportation scenarios, the main applications of aircraft include: carrying passe

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.