Japanese semiconductor material manufacturer announces full-scale development of microwave chemical recycling technology for waste plastics.

Recently, Japan's semiconductor materials giant, Resonac Holdings (formerly Showa Denko), announced a comprehensive development of chemical recycling technology in collaboration with Microwave Chemical Co., Ltd. (MWCC).

Two companies jointly launched a project rated as a "Green Innovation Fund Project" by Japan's New Energy and Industrial Technology Development Organization (NEDO). The project category is "Development of plastic raw material manufacturing technology using carbon dioxide, etc.," specifically, "Development of chemical recycling technology for producing basic chemicals from mixed plastic waste."

Although there are pyrolysis oil conversion technologies that can transform highly sorted or single-type waste plastics into blended oils such as naphtha-equivalent oil, and chemical recycling technologies that can directly convert them into basic chemical products like ethylene and propylene, the quantity of such sorted or single-type waste plastics is limited. Additionally, sorting and separating plastics incurs costs, and many types of plastics are difficult to separate. Therefore, establishing a chemical recycling technology that can directly thermally decompose mixed-state waste plastics into basic chemical products without requiring extensive sorting is expected to significantly contribute to further reducing greenhouse gas (GHG) emissions.

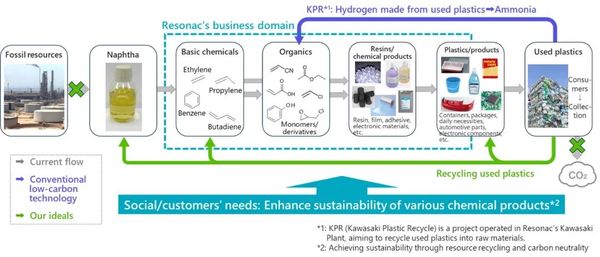

Value chain and life cycle of various chemical products

Image source: Resonac

Since 2022, Resonac and MWCC have been collaborating to develop a technology that breaks down old plastics into basic chemical products by irradiating them with microwaves. Microwaves, also used in microwave ovens, transmit energy specifically to the target material. This technology concentrates microwave energy on the old plastics, thereby efficiently breaking them down into basic chemical products.

In this project, the company will develop a novel pyrolysis technology to directly convert and recycle real mixed plastics into basic chemical products, aiming to produce useful base chemicals with a yield exceeding 60 wt% (weight percentage) and reduce CO2 emissions during production to below 0.8 kg-CO2/kg-olefin. The company's goal is to establish a recycling technology capable of processing various waste plastics at a demonstration scale of several thousand tons per year by employing innovative methods such as microwave heating for plastic pyrolysis.

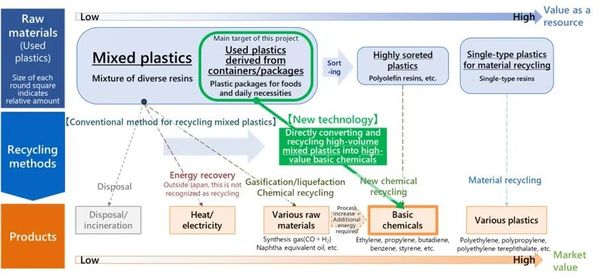

Subdivisions in the field of plastic recycling and the objectives of this project

Source: Resonac

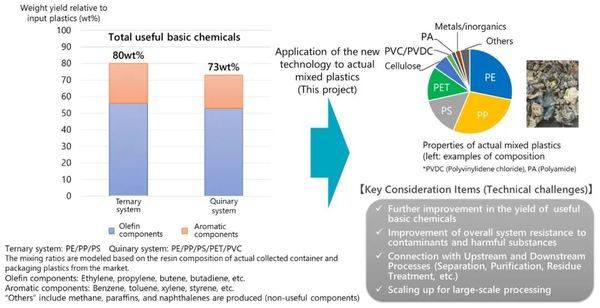

Both companies had previously experimented with a prototype plastic system, focusing on optimizing the conditions and processes for decomposition reactions. In a ternary system of polyethylene (PE), polypropylene (PP), and polystyrene (PS), they achieved a yield of 80 wt% useful basic chemicals. In a more realistic quinary system including polyethylene terephthalate (PET) and polyvinyl chloride (PVC), the yield reached 70 wt%. In this project, we will first select the decomposition process and reactor type at the laboratory (experiment) and bench (small-scale prototype) levels, then scale up to pilot (medium-scale prototype) and large-scale demonstration levels while optimizing operating conditions. Additionally, we will simultaneously identify and address potential challenges that may arise during future commercialization.

Research on plastic decomposition methods to date and the initiatives of this project

Source: Resonac

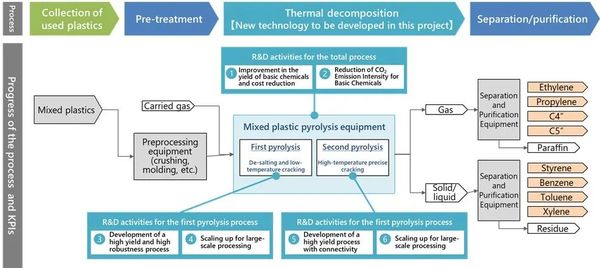

In this project, Resonac Corporation will undertake R&D activities listed in items ① to ⑥, and MWCC will conduct research using microwave heating technology from laboratory scale to benchtop scale for each of the R&D projects listed in items ① to ⑥, as well as basic design of pilot equipment.

Image source: Resonac

It is worth noting that as early as April last year, Resonac also announced the recycling of plastic waste emitted during the semiconductor manufacturing process. Through plastic chemical recycling technology, the waste is decomposed into hydrogen and carbon dioxide, which are then reused for the ammonia and dry ice needed in semiconductor manufacturing. It is reported that Resonac completed the first verification test in late January 2024 and confirmed that there were no issues during the gasification process.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Amcor Opens Advanced Coating Facility for Healthcare Packaging in Malaysia

-

ExxonMobil and Malpack Develop High-Performance Stretch Film with Signature Polymers

-

Plastic Pipe Maker Joins Lawsuit Challenging Trump Tariffs

-

Pont, Blue Ocean Closures make biobased closures work

-

Over 300 Employees Laid Off! Is Meina Unable to Cope?