Market Potential Analysis of the Plastic Packaging Coating Industry

Coating technology is widely used in the pharmaceutical packaging industry (Image source: Tritonstore)

Driven by sustainable development, the plastic industry is undergoing a transformation phase. In this process, recyclable single-material solutions are replacing multi-layer packaging, thereby promoting the development of the plastic coating industry.

According to the overview provided by Frost & Sullivan's Global Chemicals, Materials, and Nutrition Research Team in the report "Growth Opportunities in the Glass, Plastics, and Paper Packaging Barrier Coatings Industry," global food production is expected to increase by 70% by 2050. Factors such as the growing demand for pharmaceuticals from an aging population and the rapid expansion of the personal care market will drive the demand for advanced coating technologies.

The plastic packaging coating industry chain includes raw material suppliers, formulation factories, coating companies, packaging manufacturers, and brand owners, with the ultimate goal of providing high-performance, sustainable product solutions.

Suppliers provide raw materials, and formula factories process them into specialized coatings, giving them barrier properties and adhesion. Coating companies ensure the quality of the coatings, which are ultimately integrated into packaging by packaging manufacturers. Brand owners establish standards to meet regulatory, branding, and sustainability goals.

Competitive Landscape and Technological Innovation

In the global plastic packaging coatings industry, there are fewer than a hundred large-scale companies, but they are rapidly developing amid fierce competition in various aspects such as price, performance, regulatory compliance, sustainability, and innovation. Leading companies like PPG Industries, Sherwin-Williams, and Axalta Coating Systems, along with integrated firms like BASF SE and Henkel, are driving market vitality.

To cope with the changing consumer preferences and stricter regulatory requirements, manufacturers are actively developing advanced coatings such as acrylics, epoxies, and polyurethanes. These innovative technologies improve barrier performance, enhance recyclability, and increase product aesthetics, effectively addressing the growing demand for sustainability and environmentally friendly solutions.

Growth drivers and constraints in the plastic packaging coatings market

The primary driver for the growth of the plastic packaging coatings market is the promotion of recyclable single-material solutions by replacing multi-layer packaging with environmentally friendly alternatives. Technological innovations have simplified complex multi-layer structures while meeting sustainability standards. However, as brands increasingly adopt sustainable materials such as metal and paper to reduce reliance on plastics, the plastic packaging coatings market will face limitations. Additionally, the trend towards smaller, more convenient packaging has decreased the demand for coatings, particularly in the medical and food sectors. Despite these challenges, the industry's adaptation and shifts in consumer behavior will mitigate their impact, achieving a balance between innovation and sustainability.

Plastic Packaging Coating Market Forecast

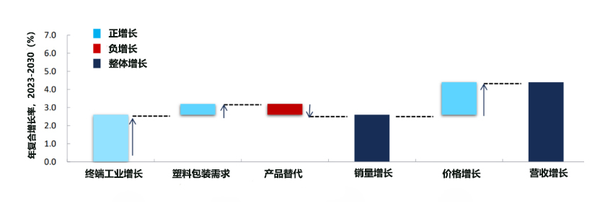

From 2023 to 2030, the global plastic packaging coatings market is expected to grow at a compound annual growth rate of 4.4%, ultimately reaching 4.07 billion dollars. The demand expansion in the Asia-Pacific region and the Middle East and Africa will drive the development of advanced coatings, while developed regions like North America and Western Europe may see a slowdown in growth due to a shift towards alternative materials.

Summary of Growth Drivers and Restraints for Plastic Packaging Coatings, Global, 2023-2030. (Image source: Frost & Sullivan report)

Polyvinylidene chloride (PVdC) coatings will remain the most advanced barrier coating technology, while aluminum oxide (AlOx) and silicon oxide (SiOx) will experience rapid growth due to their excellent barrier properties and reduction in plastic usage. Antimicrobial coatings will continue to hold a significant position, with the largest market share in North America, followed by the Asia-Pacific region and Europe.

With the increasing pressure for sustainable development, the advancement of recyclable materials and recycling infrastructure will determine the future of the plastic packaging coatings market.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories