【Medical Section】Modification Effects of Vacuum Plasma Cleaning Machines on Medical Material Surfaces

One, Invisible Organic Compounds

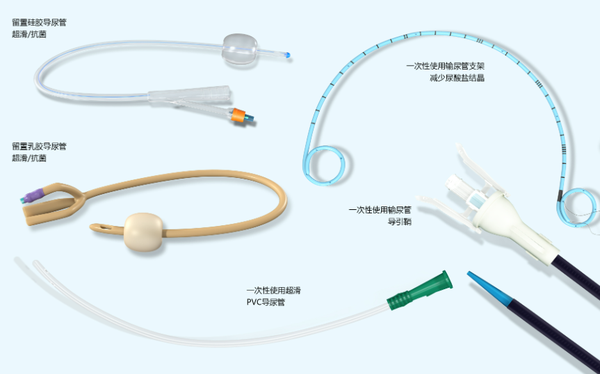

Image source: Internet, infringement deletion.

The paradox of biomaterials lies in the pursuit of perfect balance between strength and flexibility, which leads to a surface that tends towards "inertness." Just like a non-stick pan coated with Teflon, materials such as polyurethane and PEEK are inherently resistant to any intimate contact with coatings.

-

Molecular-level "oil film": Residual demulsifiers from injection molding and silicone oil adsorbed during sterilization form a contamination layer 5-10 nm thick.

-

The smooth trap: Mirror-like polishing reduces mechanical mating opportunities, with coating adhesion below 2 N/cm².

-

Chemical apathy: The density of functional groups on the material surface is less than 5/μm², making it difficult to form stable chemical bonds.

II. Vacuum Plasma, Weaving Capture Nets at the Atomic Scale

1

Supramolecular cleaning technique

High-energy electron beams precisely bombard the molecular chains of pollutants, fragmenting them, which are then抽出由真空泵抽离。 (注:最后一句似乎在原文中不完整,因此我将其保留为“抽出由真空泵抽离”。 如果有更多上下文信息,可以提供完整的句子以便更准确的翻译。) 如果只需要翻译前半部分,那么答案将是: High-energy electron beams precisely bombard the molecular chains of pollutants, fragmenting them, which are then drawn away by a vacuum pump.

The residual organic carbon content decreased from 1200 ppm to less than 50 ppm.

2

Topological Structure Revolution

- Fabricate hexagonal pits in the range of 100-500 nm through reactive ion etching (RIE).

The specific surface area increases by 17 times, creating a physical anchoring matrix for the coating.

3

Chemical Bond "Seeding Program"

- Injecting oxygen-containing polar groups reduces the surface contact angle from 112° to 32°.

The binding energy is increased to 8.3 times that of the untreated material.

Survival Rules for Medical-Grade Surface Treatment

1

More demanding than manufacturing in healthcare.

-

The surface roughness Ra of the equipment should be less than 0.2 μm to eliminate niches where microorganisms can hide.

-

Fully compliant with the YY/T 0287 Medical Device Quality Management System

-

Develop a medical-specific tracing system, with automatic machine locking when parameter deviations exceed limits.

Four, does your medical coating encounter these problems?

Perhaps it's time to reassess the material surface when faced with these scenarios.

-

The drug-eluting stent's controlled-release layer cracks and crystallizes after gamma ray sterilization.

-

The antibacterial coating of absorbable sutures fails prematurely in vivo within 3 weeks.

-

The cell affinity layer of the artificial cornea has micro-scale "blind spots".

Conclusion

From a 0.1μm coating gap on a synthetic blood vessel to a medical breakthrough impacting millions of patients' quality of life, the advancement of surface engineering has never been more crucial. In the long river of evolution in biomedical materials, Kunshan Puleisi wishes to be the ever-spinning "nanometer loom," weaving energy codes for every encounter between coatings and substrates.

Kunshan Plestar, as a deep player in the field of surface treatment,始终保持对技术可能性的探索。Whether you are a materials engineer, a specialist researcher, or simply a technical enthusiast, welcome to explore the boundaries of plasma technology with us—because every process evolution may begin with an unanswered "why."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories