National-level certification! Donghua Machinery's intelligent manufacturing service capability has been rated as Class A.

Wish

Congratulations

We, Donghua Machinery, have actively applied for the "Classification and Grading Assessment of Intelligent Manufacturing System Solution Providers (Third Batch)." After rigorous evaluation, we are pleased to announce that Donghua Machinery's service processes comply with the national standard GB/T 43554-2023 "General Requirements for Intelligent Manufacturing Services," and our integration and implementation capabilities have reachedLevel A!

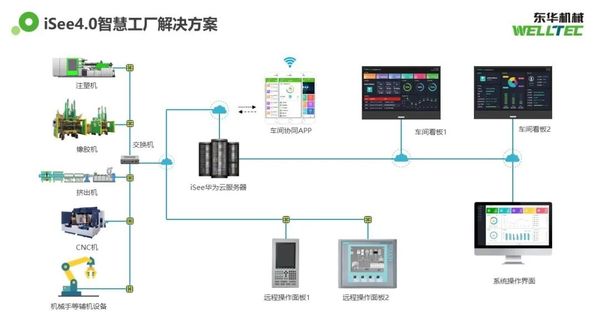

iSee4.0: The Core Engine of Intelligent Manufacturing

ISEE 4.0 system interface screenshot demonstration

iSee4.0 Intelligent Management Cloud PlatformAs the star product of Donghua Machinery, it is a key force in helping enterprises move towards Industry 4.0. Based on the Internet of Things for industrial equipment, it integrates cutting-edge technologies such as cloud computing and big data to create a data-driven intelligent production management platform for enterprises.

Core advantages of iSee 4.0

01

Visualizing Data and Scientific Decision Making

Through a comprehensive and intelligent IoT cloud platform, iSee4.0 can collect and analyze production data in real-time, providing enterprises with precise decision-making support.

02

Intelligent Scheduling and Lean Production

Convenient and efficient production planning management functions help enterprises optimize production processes and improve production efficiency.

03

Global monitoring and real-time push

Macroscopic equipment visualization management enables enterprises to monitor the overall production process in real time and promptly respond to various production issues.

Empowering intelligent manufacturing, iSee4.0 is in action.

iSee4.0Not only is it a management platform, but it is also a powerful tool for driving the intelligent transformation of the manufacturing industry. It provides strong support for enterprises in multiple aspects.

Resource Allocation Optimization

Integrate production equipment, molds, auxiliary machines, and other resources into unified management to provide support for efficient production.

Process optimization support

By collecting data from the production process, provide the basis for process managers to optimize the process.

Strengthening Quality Control

Provide information on operational specifications, quality inspection standards, etc., and combine data analysis to achieve quick tracing and resolution of quality issues.

Future Outlook

This evaluation recognizes Donghua Machinery's efforts and achievements in the field of intelligent manufacturing.iSee4.0 systemWe will take this opportunity to further deepen the research and application of intelligent manufacturing technologies, continuously optimizing and advancing our efforts.iSee 4.0 systemTo provide more enterprises with high-quality intelligent manufacturing solutions, assist the manufacturing industry in transforming towards intelligence and digitalization, and move towards a more brilliant future!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."