Ningbo Color Mother, three major projects terminate two! Is project technical transformation a last resort?

On March 25, the Ningbo Ecological Environment Bureau Yinzhou Branch announced the 36,000-ton color masterbatch technological transformation project of Ningbo Color Masterbatch Co., Ltd., marking the company's strategic focus shifting towards optimizing existing production capacity and technological upgrades.

It is worth noting that this public notice also disclosed Ningbo Color Mother's latest decisions on its two previous fundraising projects—the company, due to the need for an IPO, plans to implement the "annual production of 20,000 tons of high-end products.""Color masterbatch project""Regarding the 'Research and Development Center Upgrade Project,' as of now, these two projects have not been implemented and are not planned to be implemented."

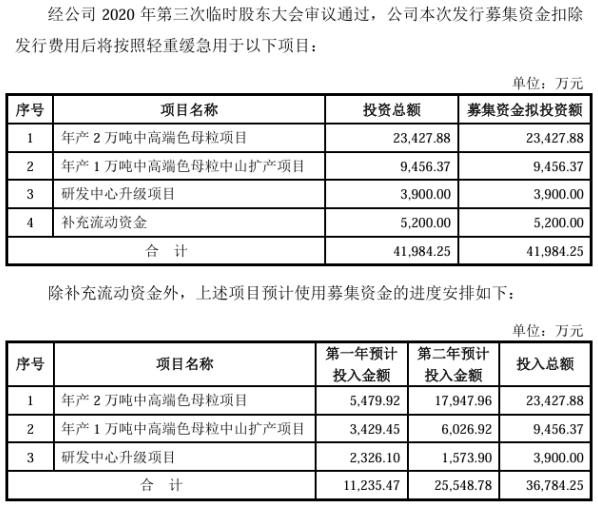

Ningbo Cama was listed in June 2021. According to its prospectus, it planned to raise funds of 419,842,500 yuan, which would be used for the following projects in order of priority: annual production of 20,000 tons of mid-to-high-end masterbatch, expansion of annual production of 10,000 tons of mid-to-high-end masterbatch in Zhongshan, R&D center upgrade, and supplementary working capital.

Source: Ningbo Masterbatch Prospectus

Annual production of 20,000 tons of mid-to-high-end masterbatch project: an investment of 234.2788 million yuan is planned to technically transform the company's original masterbatch production line, adding a capacity of 12,000 tons/year of black masterbatch and 8,000 tons/year of white masterbatch. The construction period is 24 months.

R&D Center Upgrade Project: Ningbo Color Master plans to invest 39 million yuan to expand the existing R&D center, improve R&D and testing equipment, introduce R&D technical talents, and enhance the overall technology and equipment level of the R&D center. The construction period is 24 months.

It is worth noting that according to the originally planned construction schedule, the two major fundraising projects of Ningbo Color Masterbatch were supposed to be completed and put into operation within the established timeframe. However, in the financial report released by Ningbo Color Masterbatch in 2023, it was stated that the completion of these two projects will be delayed until June 2025.

The company's "Annual Production of 20,000 Tons of Mid- to High-End Masterbatch Project" plans to utilize part of the old factory buildings and related facilities of the dismantled company, and introduce advanced production lines and strengthen production management to achieve the upgrade of the product production line.

The implementation location has been updated to include a new subsidiary in Chuzhou, and the implementation method has been changed from partial demolition and construction of old factory buildings to renovation of old factory buildings and construction of new factory buildings.

The company has extended the scheduled date for the fundraising project to reach its usable state to June 23, 2025.

The project was put into operation in June 2023, but the initial production capacity was not fully utilized, so it failed to achieve the expected returns.

After prudent evaluation and comprehensive consideration, the company has postponed the date when the fundraising investment project reaches the预定可使用状态 (预定 ready-to-use state) to June 23, 2025. (Note: The phrase "预定可使用状态" is partially in Chinese. In full English, it translates to "预定 ready-to-use state". For clarity in the context of project management, it typically means the project is ready for its intended use. Thus, a more precise translation would be: "After prudent evaluation and comprehensive consideration, the company has postponed the date when the fundraising investment project reaches the ready-to-use state to June 23, 2025.")

However, in the environmental impact report table released in March 2025, it was stated that the company, due to its need for listing, commissioned the preparation of the "Ningbo Masterbatch Co., Ltd. Additional Production of 20,000 Tons of High-end Masterbatch Production Line" and the "Ningbo Masterbatch Co., Ltd. R&D Center Upgrade Project" in 2020, and obtained approval from the Yinzhou District Environmental Protection Bureau of Ningbo City (Yin Huan Jian [2020] No. 106, Yin Huan Jian [2020] No. 107).So far, these two projects have not been implemented and are planned not to be implemented anymore.

36,000-ton masterbatch technology transformation project

Changes in Fundraising Projects: Multiple Practical Considerations

The 36,000-ton masterbatch technological transformation project origin:

Ningbo Colour Masterbatch commissioned the preparation of an environmental impact assessment report form for the annual production of 20,000 tons of plastic new material multifunctional masterbatch project in June 2016.

The project passed the completion environmental protection acceptance in 2017.

Due to market demand, the company is carrying out technical renovations on the production line and supporting facilities of the original project, which has an annual production capacity of 20,000 tons of plastic new material multifunctional masterbatch (replacing some production equipment, replacing cooling towers, and adding waste gas treatment facilities, etc.). After the renovation, the annual production capacity of 36,000 tons of mid-to-high-end color masterbatch can be achieved.

The total investment for this technological transformation project is 8.5 million yuan.

The termination of the two major IPO fundraising projects not only means a waste of previous investments, but also could potentially damage the company's reputation and market confidence. Although the newly initiated technology renovation project seems to be a move towards technological upgrades, whether it can achieve the expected results remains uncertain.

The "variations" of Ningbo color masterbatch may well be a true reflection of the industry's transformation pains, reminding every participant that in fierce market competition, there are no eternal winners; only by continually adapting to changes can one survive in the market.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."