Overview and Analysis Report on the Development and Market Competition Landscape of China's Pharmaceutical Plastic Packaging Industry in 2025

Pharmaceutical packaging mainly refers to the packaging of drug formulations, that is, the packaging and containers that come into direct contact with the drugs. Pharmaceutical packaging is an indispensable part of drugs, running through the entire process of drug production, circulation, and use. Currently, the main packaging materials in the pharmaceutical industry include glass, plastic, rubber, metal, and other types. Among them, medical plastic packaging is made of synthetic or natural high molecular compounds as the basic components, which are molded during processing, and the products can maintain their shape. From the perspective of application fields, medical plastic packaging products can be divided into five major categories: composite films (bags), injection container and components, plastic bottles, tubes, boxes, and components (excluding ophthalmic preparation packaging), and other plastic packaging. From the perspective of raw material types, pharmaceutical plastic packaging products can be classified into PE, PP, PET, and other raw material types.

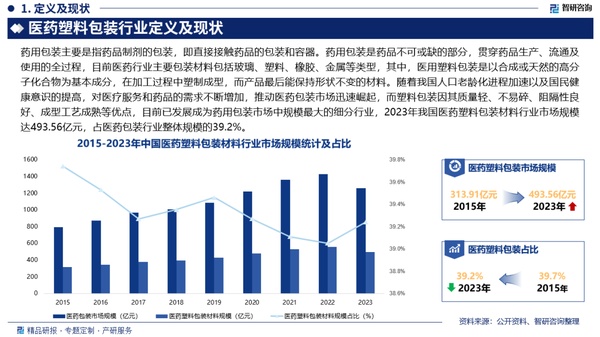

As the aging process of our country's population accelerates and the national health awareness improves, the demand for medical services and pharmaceuticals continues to increase, driving the rapid rise of the pharmaceutical packaging market. Due to its advantages such as light weight, non-fragility, good barrier properties, and mature molding processes, plastic packaging has now developed into the largest sub-sector in the pharmaceutical packaging market. In 2023, the market size of China's pharmaceutical plastic packaging materials industry reached 49.356 billion yuan, accounting for 39.2% of the overall scale of the pharmaceutical packaging industry.

In the future, as environmental regulations become increasingly stringent, the pharmaceutical plastic packaging industry will accelerate its transformation towards a green and environmentally friendly direction. The research and development, as well as the application of eco-friendly materials such as biodegradable materials and bio-based plastics, will become mainstream. The construction of recycling systems and plastic packaging recovery will also become a key focus for the future development of enterprises. In addition, with the rapid development of the pharmaceutical industry, especially in the fields of innovative drugs and biopharmaceuticals, the demand for high-end pharmaceutical packaging will significantly increase. Furthermore, to conserve resources and reduce costs, the trend towards lightweight pharmaceutical plastic packaging will become more evident. Through the application of new materials and improvements in processes, enterprises can ensure the strength and functionality of packaging while reducing the amount of raw materials used, achieving lightweight production.

The upstream of the pharmaceutical plastic packaging industry mainly includes plastic raw materials such as polyethylene, polypropylene, polyester, polyvinyl fluoride, and polyvinylidene chloride, as well as other raw materials like adhesives, inks, protective coatings, and additives, and equipment manufacturing industries; the midstream is the production and manufacturing stage of pharmaceutical plastic packaging, including the manufacture of various packaging products such as plastic bottles, plastic bags, straws, bottle caps, ampoules, and medicinal films; the downstream is the application market, mainly comprising major domestic producers of chemical drugs, traditional Chinese medicine, and biopharmaceuticals.

Due to the high requirements for technology and capital in the pharmaceutical packaging industry, the concentration of the industry in the international market is very high. Companies such as Amcor Group, with large business scale, high-tech content, and a rich product structure, occupy the main market share; while the domestic market is relatively more dispersed. However, with the improvement of environmental standards and the increasing demands from downstream pharmaceutical companies for research and development, testing levels, and independent innovation capabilities of pharmaceutical packaging material manufacturers, the competition among producers in China's pharmaceutical plastic packaging industry is gradually shifting from price competition to all-round competition in terms of technology, brand, and service. Some small and medium-sized enterprises that cannot adapt to the industry development trends will be eliminated, merged, or acquired, and the concentration of the industry will also gradually increase, with the brand advantages of leading companies becoming increasingly evident.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories