PMMA——Small Microspheres, Big Applications

01

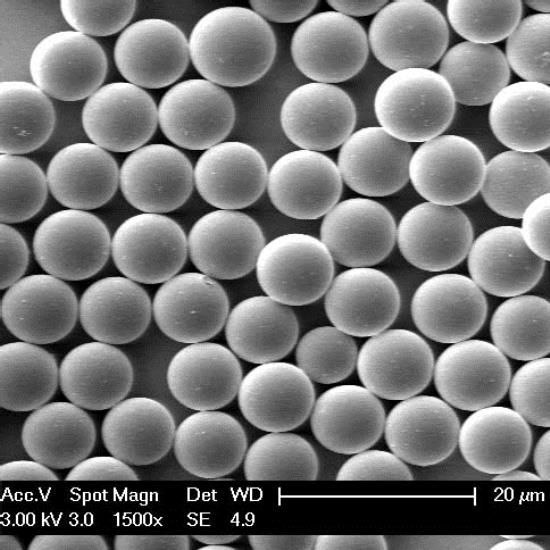

In the fascinating world of materials science, PMMA microspheres are a shining star. PMMA, or polymethyl methacrylate, is a high-molecular-weight polymer. Simply put, PMMA microspheres are tiny spherical particles composed of polymethyl methacrylate. These microspheres typically appear as fine white powdery granules, resembling delicate snowflakes. Their particle size commonly ranges from tens of nanometers to several micrometers. Despite their minuscule dimensions, they possess unique properties and vast application potential. Don’t be fooled by their small size—they play a significant role in numerous fields.

02

(1) Emulsion Polymerization Method

Emulsion polymerization is a commonly used method for preparing PMMA microspheres. The principle involves dispersing methyl methacrylate monomer in an aqueous phase under the action of an emulsifier, forming a stable emulsion system. The monomer is then polymerized by an initiator to produce PMMA microspheres. In the specific operation, an appropriate emulsifier, such as sodium dodecyl sulfate, must be selected, dissolved in water, and form an aqueous phase. Next, methyl methacrylate monomer is added to the aqueous phase and dispersed evenly under stirring. Then, a suitable amount of initiator, such as potassium persulfate, is added to initiate the monomer polymerization reaction. During the reaction process, it is necessary to control temperature and stirring speed properly to ensure that the microsphere size and distribution meet the requirements. The advantage of emulsion polymerization is that it can produce PMMA microspheres with smaller sizes and narrower distributions, and the performance of the microspheres can be regulated by changing the reaction conditions. However, this method has relatively high requirements for reaction conditions, such as strict requirements for the acidity and alkalinity and temperature stability of the reaction system. Moreover, the removal of the emulsifier may bring some subsequent processing issues.

(2) Suspension Polymerization

Suspension polymerization is also an important method for preparing PMMA microspheres. The principle involves suspending methyl methacrylate monomer droplets in a dispersing medium (usually water) in the form of small droplets. With the aid of stirring and stabilizers, the monomer droplets can maintain a stable suspension state. Initiators are then added to trigger the polymerization reaction, resulting in the formation of PMMA microspheres. In the process, the monomer, initiator, and appropriate stabilizers are first introduced into a reaction vessel. High-speed stirring disperses the monomer into small droplets and evenly suspends them in water. The role of the stabilizer is to prevent the monomer droplets from coalescing, with common stabilizers including polyvinyl alcohol. During the reaction, it is essential to strictly control the stirring speed and temperature to ensure the size and quality of the microspheres. Compared to emulsion polymerization, suspension polymerization has a relatively simpler process. The microspheres produced typically range from tens to hundreds of micrometers in size, and they exhibit good hardness and wear resistance. However, the particle size distribution of microspheres prepared by suspension polymerization tends to be wider, and their surface smoothness may not match that of microspheres prepared by emulsion polymerization.

03

Biomedical aspect

In the field of biomedicine, PMMA microspheres are playing an increasingly important role and contributing to human health. They can serve as a crucial component of drug delivery systems, enabling precise drug delivery and controlled release. By encapsulating drugs within PMMA microspheres or adsorbing drugs on their surface, and then injecting these drug-loaded microspheres into the body, the microspheres can slowly release the drug at specific sites, achieving a sustained therapeutic effect. This controlled release not only enhances the efficacy of the drug but also reduces its toxic side effects, as the drug is gradually released at the desired location rather than entering the body all at once, minimizing potential harm to other parts of the body. For example, in the development of some anticancer drugs, using PMMA microspheres as drug carriers allows the drug to target tumor sites more precisely, improving treatment efficacy while reducing damage to normal tissues. Additionally, PMMA microspheres have potential applications in tissue engineering. They can act as scaffold materials, providing a favorable environment for cell growth and tissue repair. Due to their excellent biocompatibility, cells can adhere, proliferate, and differentiate on the surface of PMMA microspheres, thereby promoting tissue regeneration and repair. In bone tissue engineering, researchers are exploring the use of PMMA microspheres as scaffolds to guide bone cell growth, offering new solutions for fracture healing and bone defect repair.

(II) Cosmetics Sector

In the world of cosmetics, PMMA microspheres are a "star ingredient." They are often used as fillers to cleverly improve the texture and feel of products, elevating the user experience of cosmetics. Imagine adding an appropriate amount of PMMA microspheres to foundation—they disperse evenly within it, making the foundation's texture more delicate and smooth, gliding on the skin like silk. Moreover, these microspheres can enhance the foundation's coverage, giving the skin a flawless and smooth appearance. In skincare products, PMMA microspheres also play a unique role. They can act as carriers, encapsulating certain active ingredients and releasing them slowly, thereby prolonging the duration of these ingredients on the skin and improving skincare efficacy. For example, in skincare products containing active ingredients like vitamin C, the addition of PMMA microspheres allows vitamin C to remain more stable and continuously exert its antioxidant effects, helping the skin combat free radical damage and delay signs of aging.

With the continuous advancement of technology, the research and application of PMMA microspheres are moving toward more diversified and refined directions. In terms of preparation methods, researchers are actively exploring novel techniques such as microfluidics and template methods to achieve more precise control over the particle size, morphology, and performance of PMMA microspheres. These new approaches are expected to produce PMMA microspheres with narrower size distributions and superior properties, meeting the demands of high-end applications.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.