PTS | Paper Tip Revolution: Making Plastic Blisters Completely "Retire"?

This issue takes you to explore the "paper blister" technology jointly launched by German processing and packaging technology supplier Syntegon and Finnish packaging material manufacturer Huhtamaki. This innovation replaces traditional plastics with renewable paper-based materials, achieving a triple breakthrough in environmental protection, safety, and convenience for pharmaceutical packaging through precision craftsmanship.

From lab to pharmacy shelf, how does this paper redefine the medication experience?

1 Eco-friendly: Ending "plastic dependency" with a green closed loop. Huhtamaki's patented coating technology seamlessly integrates the barrier layer with the paper base, achieving "tear and recycle," which can be regenerated through curb-side recycling systems without complex sorting. Compared to traditional plastic blisters, paper blisters reduce microplastic pollution by 90% over their lifecycle, providing pharma companies with a quantifiable and traceable low-carbon pathway.

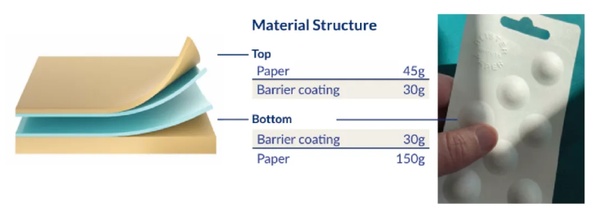

2 Protection: The "invisible armor" of pharmaceuticals, as the first FSC™ certified paper-based blister container, meets stringent pharmaceutical packaging safety requirements. The Push Tab Paper coating, made of a thermoformable base material and a covering film with a barrier coating, provides moisture and oxygen barrier properties comparable to traditional blister packaging made of single PVC or aluminum foil. Through Syntegon's high-precision thermoforming technology, the paper-based material can be accurately shaped to create customized holes ranging from 3 to 10 millimeters, tightly enclosing various forms of tablets and capsules.

Practical: Say goodbye to "inhuman design." The one-push cover membrane adopts a "light push to open" design, allowing medicine to be accessed with a simple press of a finger, eliminating the pain points of tearing aluminum film or breaking tablets. The surface of the blister supports double-sided high-definition printing, allowing for medication instructions, brand identification, and even braille information to be directly presented, eliminating the need for outer boxes and paper instructions.

The "Cross-Border Ambition" of Paper Blister Packaging The magic of paper blisters goes beyond pills. Carmex lip balm uses pre-formed paper trays with hanging holes, eliminating outer boxes while saving 8 tons of plastic. Atlantic Packaging's Paperform solution extends paper blisters to cosmetics, electronic accessories, and more—featuring curved compartments, multi-layer structures, and even transparent window designs, turning packaging into a brand billboard. From pills to daily essentials, paper blister packaging is reshaping packaging logic in the name of sustainability.

Syntegon and Huhtamaki are replacing plastic with renewable paper-based materials, reducing microplastic pollution by 90% through "tear and recycle" technology, while providing protective performance comparable to traditional materials. This "paper" revolution is not only a breakthrough in technology but also a collective action towards a greener future globally. The future of packaging may only require the imagination of a single sheet of paper.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage