Shengquan Group breaks 10 billion!

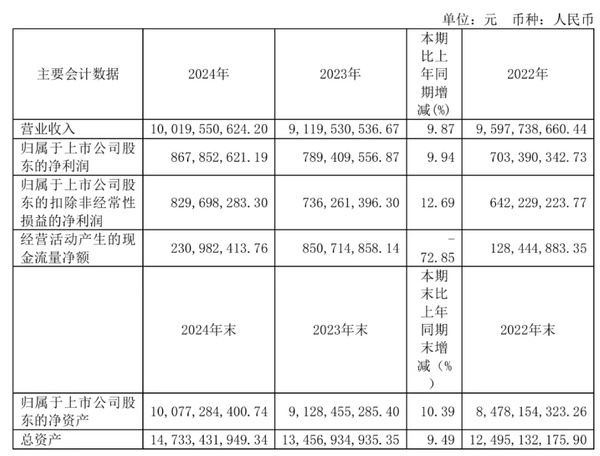

On March 31, Shengquan Group released its 2024 annual report. During the reporting period, it achieved operating revenue of 10.02 billion yuan, an increase of 9.87% year-on-year; net profit attributable to shareholders of the listed company was 868 million yuan, an increase of 9.94% year-on-year. At the end of the reporting period, total assets were 14.733 billion yuan, total liabilities were 4.168 billion yuan, the asset-liability ratio was 28.29%, and the total equity attributable to parent company shareholders was 10.077 billion yuan.

Source of the image: Announcement from the listed company

On the same day, the company also released a voluntary disclosure announcement regarding the expected performance increase for the first quarter of 2025. According to preliminary calculations by the finance department, it is estimated that the net profit attributable to the owners of the parent company will be between 200 million and 215 million yuan, representing a year-on-year increase of 45.58% to 56.49%. The net profit attributable to the owners of the parent company after deducting non-recurring gains and losses is expected to be between 183 million and 198 million yuan, representing a year-on-year increase of 45.02% to 56.91%.

The reason for the growth is:

(I) The rapid development of AI computing power, high-frequency communication, and semiconductor packaging is driving a surge in demand for advanced materials. The company focuses on the field of advanced electronic materials, with products covering the entire semiconductor packaging, PCB, and copper-clad laminate产业链. Leveraging its advantages in technology research and development, product manufacturing, and quality performance, the company has seen a significant increase in orders for high-value products. Existing capacity achieves full production and sales by the end of each quarter.

(2) The 300-ton/year porous carbon production line was completed and put into operation in Q3 2024, achieving full production and sales. The 1,000-ton/year porous carbon production line will be completed in February 2025 and gradually commissioned for production. During the reporting period, batch supply has already been achieved, effectively meeting the demand for high-energy-density batteries in the consumer electronics and power battery sectors.

(3) The "1 Million Ton/Year Biomass Refining Integration (Phase I Project)" at the Daqing production base has been operating steadily, with continuously improving capacity utilization rates, achieving reduced losses during the reporting period.

The information shows that Shengquan Group has developed a relatively complete and diverse industrial chain, including biomass chemical raw materials (cellulose, hemicellulose, lignin, etc.), synthetic resins (furan resin, phenolic resin, cold box resin, epoxy resin, etc.), and composite materials (phenolic foam boards, light steel, etc.). This allows them to fully leverage the advantages of their industrial chain to collaborate on technology research and development and market expansion.

In the field of biomass new materials, Shengquan Group has been involved in the biomass industry since its establishment in 1979. The "Shengquan Method" for integrated biomass refining technology developed by the company was included in the National Development and Reform Commission's "Green Technology Promotion Directory" (2020). This technology is environmentally friendly, highly efficient, and energy-saving, systematically addressing the global challenge of efficiently separating the three main components—cellulose, hemicellulose, and lignin—in straw, achieving high-value utilization and producing hundreds of products.

Shengquan Group has further expanded the high-value applications of biomass by relying on its independently developed "Shengquan Method" biomass refining integrated technology.

The world's first million-ton "Shengquan Method" plant straw refining integrated project (Phase I) has been fully put into operation in Daqing City, Heilongjiang Province. As a global leader in green and energy-efficient comprehensive utilization of biomass straw, the Phase I project invested and constructed by Shengquan Group can process 500,000 tons of straw annually, producing a series of green bio-based products such as biomass resin carbon, hard carbon anode materials, high-activity lignin, furfural, pulp, bio-methanol, and biodegradable materials.

High-activity lignin extracted from straw can regulate the molecular weight of high-activity lignin through differences in process technology conditions according to its downstream application needs, thus meeting the requirements of different products. Currently, high-activity lignin produced in Daqing has been successfully applied in the production of dye dispersants and oilfield aids. It has achieved breakthroughs in areas such as polyurethane and phenolic resins. Related products are being promoted in the market, while applications in rubber additives, furan resins, refractory materials, carbon black, and other fields are under development.

Biomass resin carbon extracted from straw is formed by the molecular rearrangement and carbonization of the lignin portion after the comprehensive utilization of three elements through a stepwise separation process. It has uniform particle size, high bulk density, low ash content, and a low heating value exceeding 5000 kcal/kg. As a zero-carbon raw material, it can replace coal-based fuels for direct combustion power generation, and it can also be further processed into battery hard carbon materials and green bio-methanol, among other clean energy sources.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Amcor Opens Advanced Coating Facility for Healthcare Packaging in Malaysia

-

ExxonMobil and Malpack Develop High-Performance Stretch Film with Signature Polymers

-

Plastic Pipe Maker Joins Lawsuit Challenging Trump Tariffs

-

Pont, Blue Ocean Closures make biobased closures work

-

Over 300 Employees Laid Off! Is Meina Unable to Cope?