"The Toy Supply Chain 'Breakout Game', the giants of the toy industry spark a 'cost revolution'!"

While the Trump administration was wielding the tariff baton, American toy giants were not only diversifying their production bases but also quietly launching a "cost revolution"!

The "American Girl" dolls from Mattel's American Girl brand are on display at the American Girl Place in Manhattan, New York.

The Trump administration escalated the trade war: imposing a 10% base tariff on almost all countries and adding heavy taxes on dozens of countries including China and Vietnam. As the two pillars of U.S. toy imports, Chinese products face a 54% overall tax rate (with an additional 34%), while Vietnamese toys are hit with a 46% tariff. According to the U.S. Toy Association, 77% of imported toys in the U.S. come from China, with Vietnam following Mexico in third place.

Industry experts warn that tax rates far exceeding expectations will lead to a surge in toy prices, with the initial impact likely coinciding with the back-to-school season this fall. "The entire industry is in chaos," said Greg Ahearn, president of the Toy Association. "This will have a huge negative impact on both consumers and the industry."

The Dilemma of Enterprises in Supply Chain Earthquakes

Toy giants Hasbro and Mattel had predicted in 2025 that the impact of a 20% tariff on China would be included in their plans to shift production to Vietnam, Indonesia, and India. However, the new tariff policy has resulted in rates of 46%, 32%, and 26% for these three countries, respectively. Eric Handler, an analyst at Roth Capital, pointed out: "The transfer of production has lost financial feasibility, and consumers will soon see price increases."

"Hey Buddy Hey Pal" company's "Magic Egg Decorator" relies on the Asian supply chain. However, in reality, China announced on Friday that it will impose a 34% retaliatory tariff on the US, exacerbating trade tensions.

The capital market "votes with its feet" in advance.

The tariff shockwave has swept through Wall Street: Mattel's stock plummeted 16.5% on Thursday, Hasbro dropped 12%, and Funko plunged 18%. Analysts predict that toy giants releasing quarterly reports this month may lower their profit guidance.

This tariff storm is reshaping the global toy industry landscape. After Mattel and Hasbro transferred part of their production capacity to Vietnam in two years, production in China has significantly decreased, while new factories in Vietnam hesitate due to tariffs.

US toy giant's strategy of diversifying manufacturing locations

Mattel has also been diversifying its manufacturing operations away from China, currently sourcing products from seven countries. China accounts for about 40% of its procurement volume, down from the previous 50%.

Due to the United States accounting for about half of the global toy sales, China's tariff risks are about 20% of the global cost of goods sold. UBS says this means that according to a 10% China tariff, Mattel's gross margin will be affected by 100 basis points, equivalent to about 12 cents per share. Mattel said that by 2027, the output of any country will not exceed 25% of its total output.

Hasbro has been expanding its manufacturing operations to countries like Vietnam and India to reduce its dependence on China. The company's management has indicated that Indonesia may be the next stop. Hasbro, headquartered in Pawtucket, Rhode Island, currently sources products from eight countries, with China accounting for 50%, down from the previous 60%. The company aims to reduce this proportion to 40% by 2026. In comparison, the average for the entire toy industry is 80% to 85% of revenue coming from China. Mexico also imposes tariffs on certain goods, representing 2% of Hasbro's production. The company does not source any products from Canada.

Reduce manufacturing costs

Despite efforts by companies to reduce costs through renegotiating supplier contracts and simplifying packaging (such as Basic Fun’s release of trayless packages), Basic Fun********: "The 54% tariff could lead to a direct price increase of 50% at the consumer level, especially for toy products with single-digit profit margins. Cost passthrough is inevitable."

Behind the hustle and bustle of the New York Toy Fair, buyers are frantically seeking alternatives. An unnamed Guangdong OEM factory manager revealed: "Walmart has asked us to reduce the thickness of plastic parts by 0.2 millimeters, but this can only offset 3% of the cost."

Battery-free electronics, minimalist packaging toys, self-assembled daily necessities... These seemingly regressive consumer trends are actually the wisdom of businesses surviving in the global trade war.

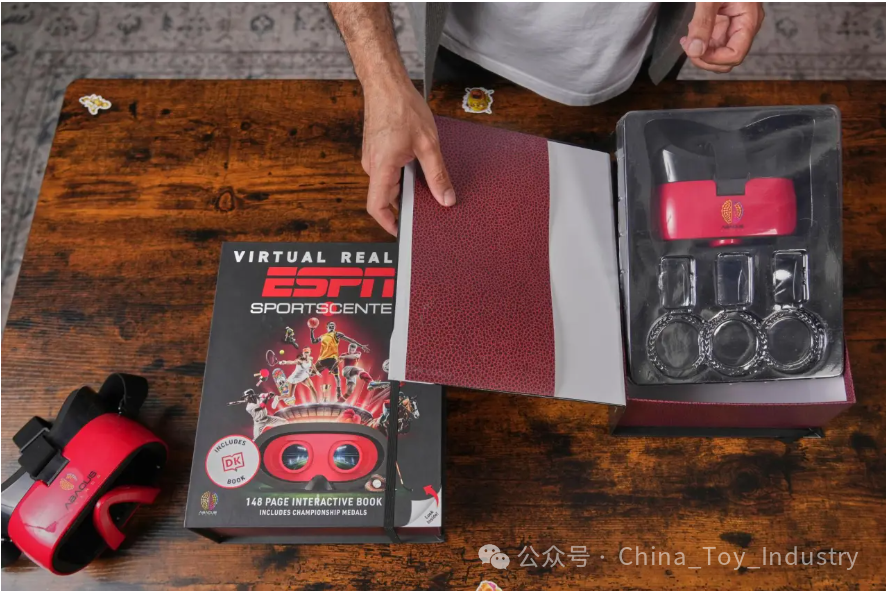

In the workshop of Abacus Brands, a Los Angeles-based educational toy company, CEO Steve Rad is showcasing a new matte packaging box: replacing the 30-cent plastic liner with a cardboard that costs only 7 cents. "Saving 3-4 cents at each spot can accumulate to offset the $10 increase in retail price," the company also plans to reduce the thickness of the paper used in the instruction manual, and expects to complete the supply chain adjustments this fall.

Steve Rad, who designs science kits and other educational toys for older kids, is showcasing a newly improved matte box (left), which will replace its black molded plastic packaging with an improved cardboard material to help offset the cost of future tariffs.

The plush toy giant Aurora World has tapped into the color economy. "Reducing the number of paint colors not only cuts material costs but also simplifies the labor process," admitted Gabriel Horikawa, general manager of the toy division. While these changes may not fully offset the impact of tariffs, they serve as a necessary buffer.

Aurora was founded in Korea in the 1980s, and by going green, it has saved more than 3 million pounds of recycled plastic.

Packaging Slimming: A Win-Win for Environmental Protection and Cost

The classic toy brand Basic Fun has designed three packaging options for Tonka trucks: a traditional box with a display window, a tray without a box, and a minimalist paper price tag. The latter two options can save costs of $1.25 and $1.75 respectively, but CEO Jay Foreman admits, "This will reduce the product's appeal and is far from offsetting the tariffs on goods from China."

The Art of Survival in the Fog of Policy

Michael Matthias, CFO of American Eagle Outfitters, revealed that the company plans to reduce the production capacity ratio in China and Vietnam from 15%-20% each to single digits. CEO Jay Schottenstein admitted, "We faced similar challenges eight years ago, and we must remain flexible— you never know where the next round of tariffs will be aimed."

Facing policy uncertainty, Peter Baum of Baum Essex in New York lamented, "This is the beginning of a global depression. An 80-year-old business run by five generations could be ruined." The company, which relocated its production capacity from China in 2019, is now facing another****in several Southeast Asian countries.

In this trade war without gunpowder, enterprises are adopting meticulous "subtraction strategies" to find a niche in the tariff storm. When innovation becomes a forced choice, the evolution of consumption patterns may reshape the commercial landscape in the post-tariff era.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.