Xiaomi SU7 high-speed collision resulted in explosion and fire, causing 3 deaths. Did Xiaomi cut corners in heat insulation and fire resistance?

On the night of March 29, news broke that three drivers from Hubei were driving a Xiaomi SU7 to Anhui for an exam when an accident occurred on the highway section from Zongyang to Qimen. This incident has been trending online, attracting the attention of many netizens and Xiaomi car owners. On April 1, Xiaomi's official website provided some responses, stating that the matter is under further investigation, and that Supersight will continue to follow the story.

The reputation of Xiaomi's cars is actually very good in the hearts of users. Many netizens even joked online about Lei Jun, saying that Lei Jun still doesn't know how to "cut corners" for the first car he made. So how about the heat insulation and flame retardant performance of Xiaomi cars? Let's take a look together.

1. The battery cells are equipped with the most energy-efficient and high-performance thermal insulation material currently available—aerogel—on both sides.

With the popularization of new energy vehicles, lithium batteries have become the mainstream power battery. However, due to their high energy density, the issue of battery thermal runaway has attracted significant attention, primarily caused by internal short circuits, overcharging, over-discharging, and high temperatures. Thermal runaway in electric vehicles can lead to battery combustion, which may ignite surrounding components and, in extreme cases, cause explosions. To address this challenge, automotive manufacturers and battery producers are increasingly focusing on aerogels, particularly for applications in thermal insulation and flame retardancy. The exceptional thermal insulation and flame-retardant properties of aerogels effectively reduce the risk of thermal runaway, enhancing battery safety and stability, making them the optimal solution for addressing safety issues in power battery systems. Additionally, their lightweight and flame-retardant characteristics are crucial for improving battery performance and achieving lightweight designs.

In order to ensure the safety of the battery, Xiaomi cars are equipped with aerogel on both sides of each battery cell, which serves to provide heat insulation and fire resistance, effectively protecting the battery's safety. Aerogel is a material with excellent thermal insulation and flame-retardant properties, and it has been widely used in the aerospace field as an insulating material. However, the biggest problem is its high cost. The battery pack of the Xiaomi SU7 uses a total of 165 pieces of aerogel as insulation material on the sides of the battery cells, instilling confidence in users regarding the thermal insulation of the battery cells.

II. Characteristics of Aerogels

Aerogels are a new generation of high-efficiency thermal insulation materials, possessing a nano-porous network structure with a gaseous dispersion medium filling the pores, making them the lightest solid in the world. Due to their unique structure, aerogels exhibit excellent performance in multiple fields such as thermal conductivity, acoustics, optics, electricity, and mechanics. Currently, commercial applications of aerogels primarily focus on their highly efficient thermal insulation capabilities, which are utilized downstream in various sectors including petrochemicals, thermal pipelines, lithium-ion batteries, construction materials, outdoor wear, aerospace, and military industries.

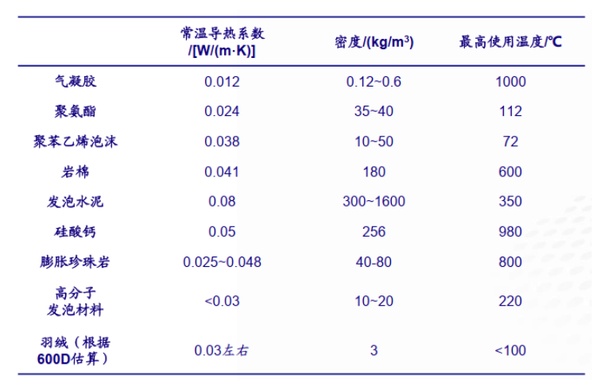

Aerogels, compared to traditional thermal insulation materials, feature low density (0.16 kg/m³), high porosity (80%-99.8%), large specific surface area (400-1000 m²/g), and low thermal conductivity (10 mW/m·K).

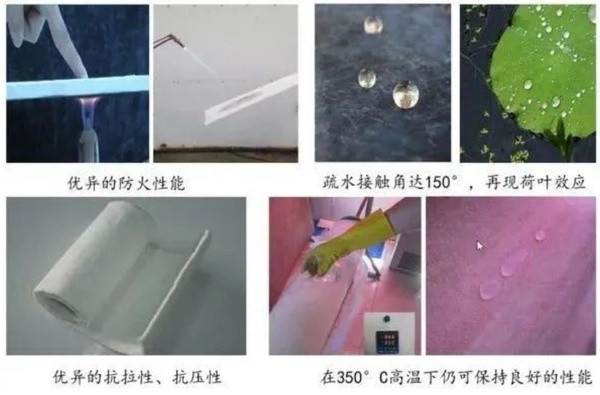

In addition, aerogel also possesses excellent properties such as fire resistance, hydrophobicity, sound insulation, adsorption, and environmental friendliness. Compared to traditional thermal insulation materials, aerogel exhibits superior thermal insulation performance. Fire resistance and hydrophobicity: it meets the national building material A1-level non-combustible standard, with a hydrophobic rate of N98%; durability: aerogel insulation materials are entirely hydrophobic, resistant to water absorption and disintegration, and have a service life of over 10 years, which is 3-5 times longer than traditional insulation materials; sound insulation and shock absorption: the three-dimensional porous network structure of aerogel can provide sound absorption, noise reduction, and shock buffering; health and environmental friendliness: the product has passed RoHS, REACH, and ELV tests and does not contain substances harmful to human health; it is an ideal adsorption material.

Compared to traditional insulation materials, aerogels offer better thermal insulation and longer service life. The ultra-low thermal conductivity of aerogels ensures excellent heat insulation effects, with thermal insulation performance being 2 to 5 times better than that of traditional insulation materials. They can be used in environments ranging from -200°C to 650°C. Additionally, the nanoscale pore structure of aerogels provides them with high compressive and tensile strength, resulting in a service life more than five times longer than that of conventional materials.

The outstanding thermal insulation performance of aerogels stems from their porous structure. The pore size of aerogels is below the mean free path of air molecules under normal pressure, causing the air molecules within the pores to remain nearly stationary, thus avoiding convective heat transfer. The extremely low bulk density of aerogels and the tortuous path of their porous structure also inhibit gaseous and solid-state heat conduction, while the nearly "infinite" number of pore walls minimizes thermal radiation. The combined effect of these three aspects almost blocks all heat transfer pathways, enabling aerogels to achieve unparalleled thermal insulation performance compared to other materials.

3. More Applications of High-Performance Materials

Xiaomi not only equips both sides of each battery cell with heat-insulating and fire-resistant aerogel, but also applies various types of high-performance plastic materials throughout the vehicle body to achieve goals of flame resistance, high-temperature resistance, and lightweight design.

In terms of power batteries, Xiaomi's battery bracket mainly uses modified PPE, PPS, and PC/ABS; the battery cover plate mainly uses modified PA6, PA66, etc.; the battery casing mainly uses modified PPS, modified PP, PPO, etc.; the battery cell and battery management system (BMS) and other components mainly use polymer materials for encapsulation and insulation. Through the application of these materials, the battery structure achieves flame retardancy, dimensional stability, chemical resistance, and high strength, ensuring the safety and durability of the battery.

In terms of electrical insulation, high molecular materials such as PPS are used in Xiaomi automotive electrical insulation components, including PPS injection molded parts like insulating sealing rings, coil bobbins, high-voltage terminals, and three-phase copper busbars. Due to their high-temperature resistance, fatigue resistance, and stable electrical insulation properties, they address the issue of degradation in electrical insulation performance and CTI values of core components in high-temperature environments.

In the field of thermal management systems, PPS modified plastics are widely used in Xiaomi's automotive thermal management systems. In radiator components, PPS plastics can withstand high temperatures and chemical corrosion under intensive use, thereby extending the service life of the radiator. For coolant pipelines, the excellent fuel and bio-fuel resistance of PPS plastics, along with their superior extrusion processing performance, make them an ideal choice for fuel pipes. Additionally, PPS plastics have been successfully applied in automotive transmission injection oil pipes due to their high pressure resistance, oil resistance, and high-temperature resistance.

From the above information, it is evident that Xiaomi Automotive has invested significant effort in battery safety and body materials, particularly by innovatively adopting aerogel as a heat-insulating and fire-resistant material on both sides of the battery cells. Aerogel, with its exceptional thermal insulation properties and lightweight characteristics, provides effective thermal runaway protection for the battery. Additionally, Xiaomi Automotive has extensively utilized high-performance plastic materials such as modified PPE, PPS, and PC/ABS. The application of these materials ensures that various parts of the vehicle body exhibit flame-retardant, high-temperature-resistant, and lightweight properties. In terms of electrical insulation and thermal management systems, high-performance polymer materials like PPS have also played a prominent role, significantly enhancing the high-temperature resistance, fatigue resistance, and electrical insulation performance of components. To further prevent vehicle self-ignition issues, it is hoped that Xiaomi Automotive will continue to explore and apply more high-quality heat-insulating and flame-retardant materials.

Source: Xiaomi Official Website, Jusuyun, RIO Material Talk, ZhuanSu World

Editor: Shenbing Shi

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Amcor Opens Advanced Coating Facility for Healthcare Packaging in Malaysia

-

ExxonMobil and Malpack Develop High-Performance Stretch Film with Signature Polymers

-

Plastic Pipe Maker Joins Lawsuit Challenging Trump Tariffs

-

Pont, Blue Ocean Closures make biobased closures work

-

Over 300 Employees Laid Off! Is Meina Unable to Cope?