Yizhumi showcases several key models for the first time at the Brazil International Plastics Show.

On March 24 local time, the highly anticipated Brazil International Plastics Exhibition (Plástico Brasil 2025) grandly opened at the São Paulo Expo Exhibition Center. The five-day exhibition not only gathered the cream of the global plastics industry but also served as a convergence of technological innovation and industry trends.

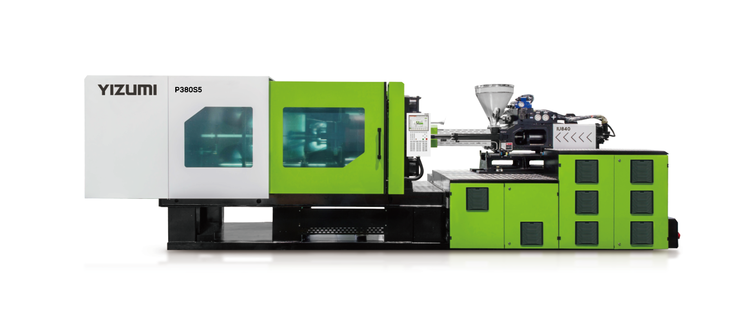

Yizumí Brazil Subsidiary, with great sincerity, joined hands with the renowned local agent Alfamach to showcase UN260A6, P380S5, UN550D1S, FF120, and SpaceA industrial 3D printer along with integrated solutions at the exhibition (booth number: C080), actively demonstrating its manufacturing capabilities to Brazilian clients.

Exhibition Plan

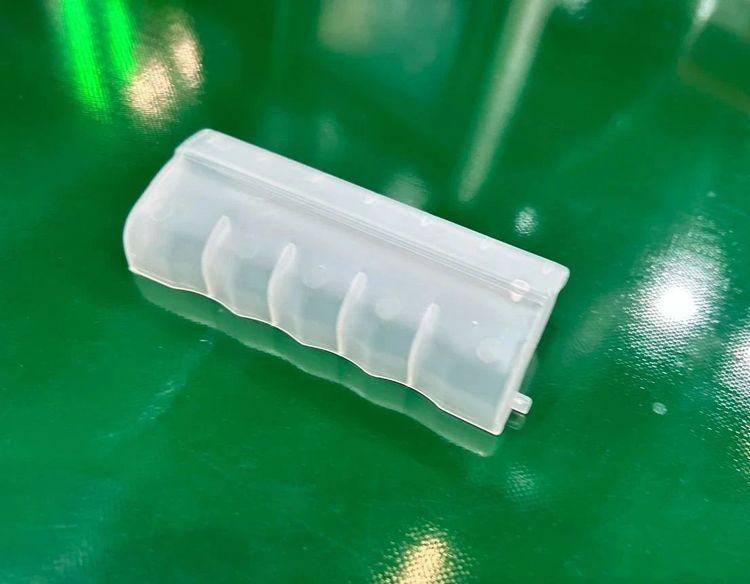

Storage Box Lid Shaping Solution

The A6 series made its debut in the Brazilian market and quickly sparked a craze, earning widespread acclaim from customers. As the全新第六代高端智能注塑机 (the all-new sixth-generation high-end intelligent injection molding machine), the A6 series stands out with its core advantages of intelligence, precision, energy efficiency, and high efficiency. It not only significantly enhances production efficiency and product quality but also effectively reduces operating costs through energy conservation and intelligent management, providing customers with better solutions. It seems like there was a part in Chinese that didn't translate directly due to it being in a different language within the text. The provided translation focuses on translating the rest of the content accurately.

In terms of intelligence, the A6 series machines are equipped with several advanced intelligent management systems. Among them, the intelligent clamping force management system can accurately adjust the clamping force according to production needs, ensuring the stability and consistency of the molding process; the intelligent energy consumption management system enables real-time monitoring and optimization control of the equipment's energy consumption, effectively reducing energy consumption and helping enterprises achieve green production.

Product Name: Storage Box Lid

Material:

Chamber count: 1

Weight: 162g

Cycling time: 20s

PET container molding solutions

The P-S5 series injection molding machine is characterized by its efficiency, precision, and energy-saving features. It not only excels in product forming but is also particularly well-suited for producing thin-walled, high-transparency, aesthetically pleasing, and textured PET containers.

In terms of molding performance, the P-S5 series injection molding machine can precisely control the molding process, ensuring that the thin-wall structure of PET containers is uniform and consistent, with minimal wall thickness deviation. Its high transparency is attributed to precise temperature control and optimized injection speed, which help avoid defects and impurities during the molding process, showcasing a high-end texture and visual appeal.

The locking unit of the P-S5 series injection molding machine adopts a completely new design, with an overall rigidity increased by 15%, shorter dry cycle time by 5%-10%, and opening mold repeatability accuracy less than ±0.4mm, ensuring efficient and stable production. The hydraulic system uses the INVT excellent system, making the entire machine respond faster with higher precision, controlling the opening mold repeatability positioning accuracy within ±0.5mm, and achieving significant energy-saving effects.

Product Name: PET Container

Material: PET

Number of cavities: 4

Weight: 30.5g

Cycling time: 8s

Storage Box Locking Mechanism Solution

The FF series electric injection molding machine adopts a modular design concept, with an injection speed range of 160mm/s to 500mm/s and an injection and mold opening/closing position accuracy controlled within 0.03mm. Compared to traditional hydraulic machines, it saves energy by 30%-50%. Its high precision, high efficiency, and high stability meet the high demands of customers for injection molding equipment.

Product Name: Storage Box Latch

Material: PP

Number of cavities: 4

Weight: 10.27g

Molding cycle: 20s

Vase Formation Solution

The SpaceA industrial 3D printer is characterized by its core advantages of high efficiency, low cost, flexible customization, and high quality. It utilizes a screw extrusion system, significantly enhancing production efficiency and enabling quick responses to market demands. At the same time, the use of granular raw materials greatly reduces costs compared to traditional methods. Additionally, it is compatible with various materials, including modified plastics and special materials, thereby meeting diverse production needs.

Product Name: Vase

Material: PP with carbon fiber

Weight: 800g

Cycling time: 1h

Storage Box Molding Solution

The D1S series two-plate servo injection molding machine is characterized by efficiency and intelligence, featuring the Austrian KEBA intelligent control system with a built-in dual-core CPU that responds quickly and offers multiple functions, significantly enhancing production efficiency and stability. Its designs, such as efficient pressure build-up and precise guidance, result in shorter dry cycle times and more stable injection accuracy, with product weight repeatability within 0.3%. This series of injection molding machines also possesses energy-saving features, significantly reducing energy consumption and providing customers with higher value and benefits.

Product Name: Storage Box

Material: PP

Number of chambers: 1

Weight: 490g

Molding cycle: 35s

As the economic giant of Latin America, Brazil's plastic market is facing dual challenges of fluctuations and recovery. In recent years, despite encountering supply chain disruptions and developmental bottlenecks in the industry structure, the Brazilian plastic industry has still demonstrated strong resilience and recovery momentum, especially in multiple sectors such as packaging, construction, automotive, and agriculture, where the demand for plastic products continues to grow.

To align with this market trend, Yizumi has actively expanded into the Brazilian market. In August 2020, Yizumi's Brazilian subsidiary officially opened in Joinville. The company not only showcases new products and technologies for injection molding machines and peripheral equipment but also provides product support and training services for customers, as well as strong technical support for local agents Alltech and Alfamach.

Instituto Tecnológico de Serviços de Vila Velha, Brazil

On this basis, Yizhimi’s layout in Brazil has been steadily expanding and deepening. To better serve Brazilian customers, the company has successively established the Yizhimi Juiz de Fora Technology Service Center, the South Caçias Technology Service Center of Brazilian agent Alltech, as well as the Yizhimi São Paulo Technology Service Center.

The establishment of these service centers has significantly enhanced Yizhim's service capability and response speed in the Brazilian market, further consolidating its leading position in Brazil. Yizhim will continue to deepen its efforts in the Brazilian market, committed to providing customers with higher quality products and services, and promoting the sustained development of the Brazilian plastics industry.

In the future, Yizhiming will continue to deepen its layout in the Brazilian market, strengthening cooperation with local upstream and downstream enterprises in the industry chain to jointly promote industrial upgrading and development in Brazil and the entire Latin American region. At the same time, the company will continuously enhance its technical strength and service level to provide better quality products and services for global customers.

*The page data is sourced from internal testing at Yizhimai, and the specific data for the equipment is subject to the customized equipment conditions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

Behind pop mart's surging performance: The Plastics Industry Embraces a Revolution of High-End and Green Transformation

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.