140,000 tons! uhmwpe expansion wave hits: Domestic Substitution Accelerates to Break Through High-End "Choke Point" Challenges

On July 15, the first phase of the ultra-high purity high molecular weight polyethylene (UHMWPE) project (140,000 tons/year) at Puxin Crystal New Energy Materials (Shanghai) Co., Ltd. in the Shanghai Chemical Industry Park achieved mechanical completion. The project successfully completed the handover, and all construction, installation, and static testing have been successfully completed, officially entering the preparation stage for production, laying a solid foundation for the comprehensive completion and high-quality production of the project.

Image source: Puxin Crystal

Zhuansu Shijie has discovered that there has been a phenomenon of numerous UHMWPE projects being launched intensively this year. So why is this happening? What UHMWPE projects will be launched in China by 2025? What is the planned production capacity? Zhuansu Shijie will take you to analyze the evolution of production capacity and the competitive landscape in this popular material field.

One,Why UHMWPE"Become""Hotcake"?

Ultra-high molecular weight polyethylene (UHMWPE) is an exceptional engineering plastic with a molecular weight typically exceeding 1.5 million, which is dozens of times higher than that of ordinary polyethylene. This unique molecular structure endows it with extraordinary wear resistance, high impact strength, excellent self-lubricating properties, and resistance to chemical corrosion, making it an indispensable key material in high-end fields such as aerospace, national defense and military industry, and marine engineering.

According to the "Key Technology Roadmap for <Made in China 2025>" released by the National Manufacturing Power Construction Strategy Advisory Committee, ultra-high molecular weight polyethylene fibers and their composite materials have been explicitly identified as key development targets, highlighting their strategic national importance.

On May 30, 2024, the Ministry of Commerce, the General Administration of Customs, and the Equipment Development Department of the Central Military Commission jointly announced the implementation of export controls on items related to ultra-high molecular weight polyethylene (UHMWPE) fibers. The release of policy dividends quickly ignited investment enthusiasm in the industry, prompting domestic companies to accelerate the layout of UHMWPE production capacity and initiate a new wave of expansion.

The explosive growth of market demand is another important factor driving the expansion of the UHMWPE industry. With the rapid development of the new energy industry, the demand for ultra-high purity UHMWPE in lithium battery separators has grown exponentially; the upgrading of the semiconductor industry has raised higher requirements for high-purity filtration materials in the chip manufacturing process; the healthcare sector continues to elevate quality standards for medical materials such as artificial joints and sutures. These high-end application fields together constitute the UHMWPE market.Golden TrackAttract capital and technology to gather quickly.

According to industry statistics, the average annual growth rate of China's apparent consumption of UHMWPE from 2020 to 2024 will remain above 15%, far exceeding the growth rate of ordinary plastic materials. However, at the same time, high-end application fields still heavily rely on imports, especially for lithium battery separator grade, chip grade, and medical grade UHMWPE, where the dependence on imports is as high as over 60%. This supply-demand contradiction provides a huge market opportunity for domestic enterprises and explains the recent phenomenon of numerous UHMWPE projects being launched intensively.

Domestic UHMWPELatest progress in capacity construction

The current domestic UHMWPE project construction showsBlossom in multiple placesIn this situation, various market entities such as state-owned enterprises, private enterprises, and joint ventures are all joining this sector, with a noticeable acceleration in capacity expansion. In terms of regional distribution, projects are mainly concentrated in East China, Northeast China, and Northwest China, forming an industrial pattern with Shanghai as the technology innovation center and production bases in places like Liaoning, Shaanxi, and Ningxia.

Puxin Crystal New Energy Materials (Shanghai) Co., Ltd.Ultra-high purity high molecular weight polyethylene projectWithout a doubt, it is the focus of the industry in recent times. On July 15, 2025, the company's first phase project in Jinshan District, Shanghai, with an annual capacity of 140,000 tons, successfully achieved mechanical completion, marking the completion of a key construction milestone for this major project with a total investment of 2.25 billion yuan. Since the project's start on June 28, 2024, the entire process from civil construction to equipment installation was completed in just 383 days, setting a new record for construction speed in the industry. Even more noteworthy is that the Polycrystalline Project adopted ...Independently developed ultra-high purity slurry method technologyThe products produced by introducing advanced equipment from Germany and Japan have significant characteristics such as high purity, high molecular weight, and high consistency, directly aligning with the highest international standards.

The strategic positioning of the Polyene Crystal project is very clear—focusing on three high-end application areas: lithium battery separators, high-end filter materials for chips, and medical materials, addressing the long-standing challenges faced in these fields.Import dependenceThe company has innovatively built an "8-hour rapid response" supply network covering Jiangsu, Zhejiang, Shanghai, and Anhui. Through a clean three-dimensional warehouse with a capacity of 15,000 tons and an intelligent storage system, the traditional 15-day supply cycle has been compressed to 8 hours, achieving a supply chain revolution of "zero inventory + rapid delivery." This model not only saves downstream enterprises tens of millions in self-built storage investments but also significantly reduces overall supply chain costs. The base is equipped with a 100,000-level clean space, precisely matching the extreme requirements for "ultra-clean and high-purity" polymer materials in the fields of chips, new energy, and medical materials.

In addition to the polyolefin crystal project, several important UHMWPE projects made breakthrough progress in the first half of 2025.

1China Chemical 5Ten thousand tons of UHMWPESmooth handover

On May 30th, the groundbreaking ceremony for the 50,000-ton-per-year ultra-high molecular weight polyethylene resin project (Phase I), invested and constructed by China Chemical City Investment Company, was successfully held, marking the project’s full transition into the pre-commissioning phase for trial production. The project commenced construction in October 2023.

Image source: Chinese Chemistry

The total investment of the project is 830 million yuan, planning to build 2 sets of ultra-high molecular weight polyethylene resin production units, with an annual capacity of 20,000 tons and 30,000 tons respectively.

According to the plan, the project will officially start production in August this year. Its main products include fibers, lithium battery separators, pipe and plate materials, and special-shaped materials, with a wide range of applications. There is a broad market prospect in various industries such as aerospace, national defense and military, marine engineering, rail transportation, municipal construction, petrochemicals, new energy materials, and pharmaceuticals.

It is worth mentioning that this project adopts advanced process technology routes with independent intellectual property rights from China National Chemical Corporation. This technology, centered on efficient catalysts, can precisely control the molecular weight of the polymer. Combined with the batch slurry polymerization process and unique stirring technology along with external circulation cooling methods, it effectively addresses the issue of material sticking to the reactor, achieving a high degree of stability in product quality, with some performance indicators even surpassing those of imported products.

2Pujie Energy Chemical 4ten thousand tonsYear UHMWPEThe installation engineering project has fully entered the sprint stage.

In May, Pujie Chemical's 40,000-ton/year ultra-high molecular weight polyethylene plant uses the ultra-high molecular weight polyethylene technology developed in cooperation with the Shanghai Institute of Organic Chemistry, Chinese Academy of Sciences, and Sinopec Shanghai Engineering Company. It utilizes ethylene and hydrogen as raw materials, hexane as a solvent, and employs efficient catalysts to produce various grades of ultra-high molecular weight polyethylene by changing operating conditions, with an annual output of up to 40,000 tons.

3Liaoyang Petrochemical Expansion UHMWPEProject approved

On April 29, the approval announcement for the capacity expansion and renovation project of LiaoYang Petrochemical's 40,000 tons/year ultra-high molecular weight polyethylene (UHMWPE) facility was released. The total investment for this project is 211 million yuan, which will upgrade and expand the existing 70,000 tons/year polyethylene facility (A/B lines).

The A line equipment remains unchanged, while only the B line equipment will undergo partial modifications. After the modifications, the production capacity of B line will increase from 35,000 tons/year to 40,000 tons/year, while also transitioning to the production of ultra-high molecular weight polyethylene products, along with the complete improvement of relevant utility and auxiliary facilities.

In recent years, Liaoyang Petrochemical has intensified its efforts to develop high-quality ultra-high molecular weight polyethylene specialized products, with molecular weights reaching 1.5 million to 6 million. This has achieved full coverage and series production from ordinary pipe extrusion grades, sheet grades, and high wear-resistant pipes to high-modulus, high-strength, and fiber grades.

4China Petroleum & Chemical Corporation's special fiber project has started construction, with an annual output of 4,000.Tons of UHMWPE

On May 18, the Sinopec special fiber project commenced construction at the Ningdong base, with a total investment of 5 billion yuan and an area of 950 acres. The project will be constructed in two phases according to the principle of overall planning and phased implementation.

Phase I will have an annual production capacity of 4,000 tons of ultra-high molecular weight polyethylene fibers and 4,000 tons of para-aramid production facilities along with supporting auxiliary facilities, with plans to be completed and put into operation by March 2027.

5Lanzhou Petrochemical 10Ten thousand tons of UHMWPEDevice process package delivery

On January 17, Lanzhou Petrochemical held a handover ceremony for the process design package of the ethylene transformation and upgrade project, including 400,000 tons/year multi-zone polymerized polypropylene and 450,000 tons/year gas-phase polyethylene.10ten thousand tonsUltra-high molecular weight polyethyleneThe completion of the handover of 3 sets of independent technology process packages from the Technology Innovation Center to the Ethylene Transformation Project Management Department marks the official transition of the polyolefin main project of the transformation and upgrading ethylene modification project from feasibility research to design and implementation.

The UHMWPE transformation plan is to retrofit the existing 170,000 tons/year high-density polyethylene plant into a 60,000 tons/year ultra-high molecular weight polyethylene plant, increasing the production of ultra-high molecular weight polyethylene by 50,000 tons/year.

6"4 at the dock"Disclosure of the adjustment plan for the ten-thousand-ton-per-year ultra-high molecular weight polyethylene project

On May 31, the adjustment plan for the new material industry park project (40,000 tons per year ultra-high molecular weight polyethylene) located at No. 66 Gangxing Avenue, constructed by Qingdao Chengzhi Huqing Chemical New Materials Co., Ltd., was announced. Due to market changes and adjustments in the company's macro layout, there have been changes in raw material supply, steam sources, and environmental protection projects. Additionally, changes in waste gas treatment measures have resulted in an increase in the emissions of major pollutants.

Image source: Qingdao Chengzhi Huaqing Chemical Co., Ltd.

The total investment of the project is 2,352.75 million yuan, covering an area of 528 acres. It is currently in the main construction phase and is expected to be operational by the end of 2025. It is reported that the first phase of the project plans to build a production line for 200,000 tons of polyolefin elastomer (POE) and a production line for 40,000 tons of ultra-high molecular weight polyethylene (UHMWPE) annually. Once completed and reaching full production, it is expected to generate an annual output value of 4 billion yuan and a profit of 700 million yuan.

Three, UHMWPEPlanned production capacity and market structure

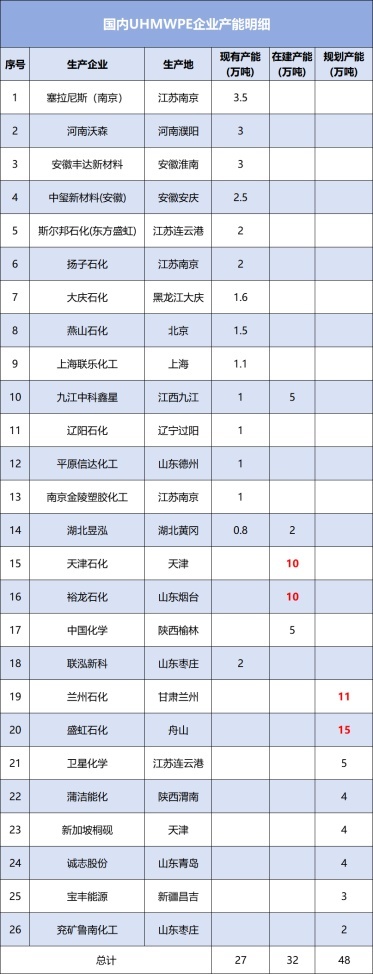

Let's take another look at the production capacity situation. As of April 2025, domestically...UHMWPEThe total existing production capacity is approximately 270,000 tons per year, with 320,000 tons under construction and an additional planned new capacity of about 480,000 tons per year.

Data sources: Guanyan World, China Chemical Information Magazine, Huachuang Securities; Mapping: Zhuansuliujie

Among them, Tianjin Petrochemical and Yulong Petrochemical both have an annual production capacity of 100,000 tons; Lanzhou Petrochemical and Shenghong Petrochemical have planned capacities exceeding 100,000 tons, with the latter's planned capacity reaching 150,000 tons, making it relatively prominent among the planned projects.

The East China region is the area with the most concentrated production capacity, with numerous enterprises gathered in Jiangsu (Nanjing, Lianyungang), Anhui (Huainan, Anqing), and Shanghai. This region has a strong chemical industry foundation and a well-developed industrial chain. In contrast, the South China region has relatively fewer manufacturing enterprises.

In terms of market size, the global ultra-high molecular weight polyethylene resin market is expected to reach USD 6.31 billion by 2030, with a compound annual growth rate of 15.8% from 2025 to 2030. According to GYR's statistics and forecasts, the market size for ultra-high molecular weight polyethylene fiber is expected to be USD 1.035 billion in 2023.

From the release of policy dividends to the explosion of market demand, ultra-high molecular weight polyethylene (UHMWPE) is unprecedented development opportunities. The intensive capacity projects launched by domestic enterprises are not only a precise response to the pain point of "dependence on high-end material imports," but also mark China's leap from "catching up" to "running alongside" and even "leading" in this strategic material field.

With the commissioning of projects such as the 140,000-ton polyolefin crystal project by Puxin and the 50,000-ton project by China National Chemical Corporation, as well as the accelerated progress of 100,000-ton projects under construction at Tianjin Petrochemical and Yulong Petrochemical, and the layout of Shenghong Petrochemical's planned capacity of 150,000 tons, the capacity structure of domestic UHMWPE will achieve optimization from "excess of general materials" to "breakthrough in high-end materials." In the future, in core fields such as lithium battery separators, chip filter materials, and medical materials, domestic UHMWPE is expected to gradually replace imports and fill the gaps in the industrial chain.

Editor: Lily

Material sources: Zhuangsu Shijie, China Chemical Information Weekly, Polyolefin People and other public reports.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Abbott and Johnson & Johnson: Global Medical Device Giants' Robust Performance and Strategies Amid Tariff Pressures

-

Overseas Highlights: PPG Establishes New Aerospace Coatings Plant in the US, Yizumi Turkey Company Officially Opens! Pepsi Adjusts Plastic Packaging Goals

-

BYD releases 2024 ESG report: Paid taxes of 51 billion yuan, higher than its net profit for the year.

-

The price difference between recycled and virgin PET has led brands to be cautious in their procurement, even settling for the minimum requirements.

-

Which brand of AI TV is good? Samsung Vision AI interprets the new industry standard with its "technical advantage."