16000-Ton Integrated Die Casting Plant Completed! Domestic Expansion Accelerates, Opportunities Arise for Plastics

Specialized Plastics VisionOn September 5th, it was announced by China State Construction Engineering Third Bureau Second Company that the world’s largest tonnage integrated die-casting factory, the Dongfeng Motor Integrated Die-Casting Industrialization Construction Project, undertaken by the Civil Engineering Company, completed its final acceptance 25 days ahead of schedule. This milestone not only signifies a critical step forward for Dongfeng Motor in the field of new energy vehicle manufacturing but also reflects the accelerating trend of integrated die-casting technology layout domestically. At the same time, as integrated die-casting demands new requirements on material performance, plastics are quietly brewing new application opportunities in this technological wave.

Dongfeng Motor leads the global innovation in die-casting technology.

The joint factory completed this time covers an area ofCovering an area of 47,000 square meters, the core configuration includes the world’s largest integrated die-casting dual production lines of 16,000 tons and 10,000 tons. Through the use of BIM technology to optimize construction procedures, the project team completed the construction 25 days ahead of the contractual schedule, demonstrating the high efficiency of Chinese manufacturing. As the world’s first automaker to introduce 16,000T integrated die-casting technology, Dongfeng Motor’s project is expected to start mass production in June 2026, with Phase I having an annual output of 200,000 units and, after Phase II reaches full capacity, a combined annual output of 600,000 units. The production will cover key components such as rear floor assemblies and battery housings.

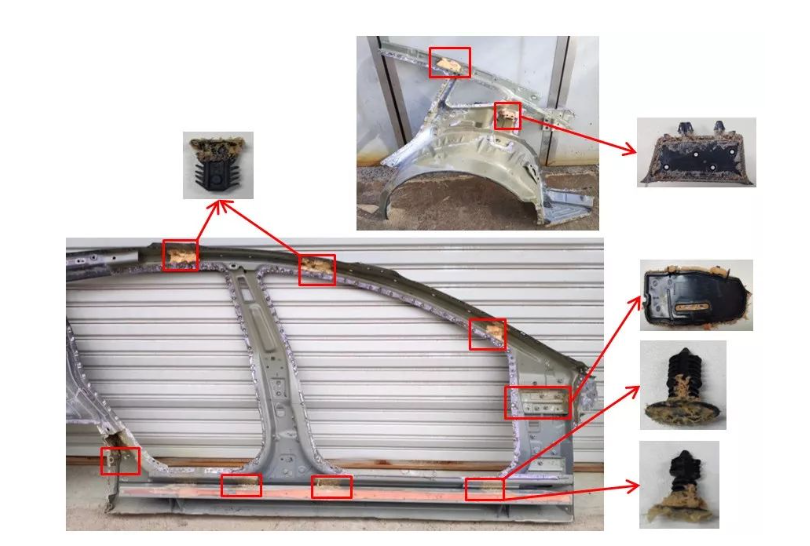

Image Source: Official WeChat Account of China State Construction Engineering Third Bureau Second Company

Integrated die casting technology uses ultra-large die casting machines to form multiple parts in one go, revolutionizing traditional automobile manufacturing.The "stamping-welding-painting-final assembly" are the four major processes. Taking the Tesla Model Y as an example, the number of rear floor parts is reduced from 171 to 1, the number of welding points is decreased from 800 to 50, manufacturing costs are reduced by 40%, and production efficiency is increased by 30%. Dongfeng Motor's layout is precisely because it recognizes the core value of this technology in terms of lightweighting, structural strength enhancement, and cost optimization for new energy vehicles.

The domestic integrated casting layout is accelerating comprehensively.

Dongfeng Motor's breakthrough is not an isolated case.Since 2024, new cars like the AITO M9, Zeekr 007, and Xiaomi SU7 have all adopted integrated die-casting technology. Emerging players such as XPeng, NIO, and Neta have also begun to invest in this area. According to statistics, over 20 car manufacturers in China have planned die-casting capacities. It is estimated that by 2025, the global integrated die-casting market size will exceed 30 billion yuan.

However, technical barriers and cost challenges coexist. Integrated casting requires optimizing alloy composition to suppress pre-crystallization, ensuring vacuum levels to enhance mechanical properties, and even Tesla initially faced such challenges.A 60% defect rate. In addition, the issue of repair costs, which consumers are concerned about, needs to be urgently addressed — integrated die-cast parts require complete replacement after a collision, which may lead to soaring repair costs. These challenges force car manufacturers to continuously push for breakthroughs in material innovation and process optimization.

Integrated die-casting with plasticWhat opportunities are there?

Amid the wave of integrated die-casting dominated by metal materials, plastics are opening up new tracks through differentiated applications. The core opportunities are reflected in two major scenarios:

NVH Performance Optimization: Filling the "Cavity Shortcomings" of Metal Die Casting

Although integrated die-casting improves the structural strength of the car body, the cavities formed within the body-in-white can easily create vibration loops, worsening the situation.NVH Performance: Traditional solutions require post-formation remedies such as sound-absorbing cotton after the car body is shaped, whereas plastics can be incorporated earlier in the design phase. Taking the Tesla Model Y as an example, PA66 nylon-based barrier blocks are pre-installed in the side cavity. During the electrophoretic baking process, these blocks expand through foaming to form a continuous sealing layer, effectively isolating noise transmission. This "pre-embedded" solution is more efficient and lightweight compared to the later addition of sound-absorbing materials.

Model Y side cavity foam material, image source: Auto Evaluation Home

Lightweighting and Functional Integration: A "Cost Reduction and Efficiency Enhancement" Approach to Replacing Metals

Tesla has replaced aluminum with nylon and fiberglass composites in components such as door interiors, audio-visual systems, and suspension systems. This type of material not only reduces weight.30%-50%, and it is also possible to integrate wiring harnesses, sensors, and other functions through injection molding processes, reducing assembly steps. For example, using plastic for the battery pack cover can prevent sealing failure caused by differences in thermal expansion coefficients of metal parts, while also reducing electromagnetic shielding costs.

The integration of die casting and plastic applications is essentially a collaborative innovation in materials science. On one hand, metal die-cast parts provide a more structured installation interface for plastics, simplifying the design complexity of plastic components; on the other hand, plastics fill cavities and isolate vibrations, compensating for the deficiencies of metal die castings in acoustic performance. This kind of...The combination of “rigidity and flexibility” is becoming a new paradigm for cost reduction and efficiency improvement in new energy vehicles.

Dongfeng MotorThe completion of the 16,000-ton die-casting factory is a microcosm of the Chinese new energy vehicle industry’s transformation from “scale expansion” to “technology-driven.” Faced with the challenge of balancing cost and performance brought by integrated die-casting, plastics demonstrate irreplaceable value in areas such as NVH optimization and lightweight integration due to their unique material properties.

In the future, asWith advances in CAE simulation technology and the decreasing cost of composite materials, plastics may become a key bridge connecting metal die-casting and intelligent electrification, injecting new momentum into the high-quality development of the automotive industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

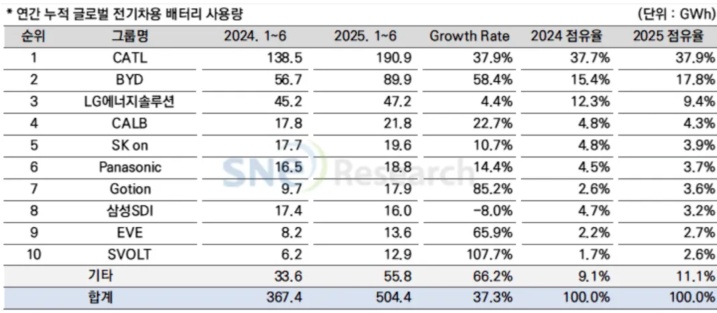

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%