2025 National Magnesium Industry Conference: Yizumi's Semi-Solid Magnesium Alloy Technology Breaks Through, Leading the Way for Magnesium Industry Upgrade

The 2025 National Magnesium Industry Conference and the 28th Annual Conference of the Magnesium Industry Branch will be held from October 20th to 22nd at the Yuncheng Convention and Exhibition Center in Yuncheng City, Shanxi Province. This conference, themed "Gathering Magnesium in Yuncheng · Smart Chain for the Future, Creating a Global Innovation Hub for Magnesium-based New Materials," aims to explore new technologies, new equipment, and new processes in magnesium processing and applications. It seeks to promote the construction of a modernized magnesium industry system, advance the green and low-carbon transformation and intelligent upgrading of the magnesium industry, thereby accelerating the large-scale application of magnesium and promoting the high-quality development of the magnesium industry.

Wonderful Speech

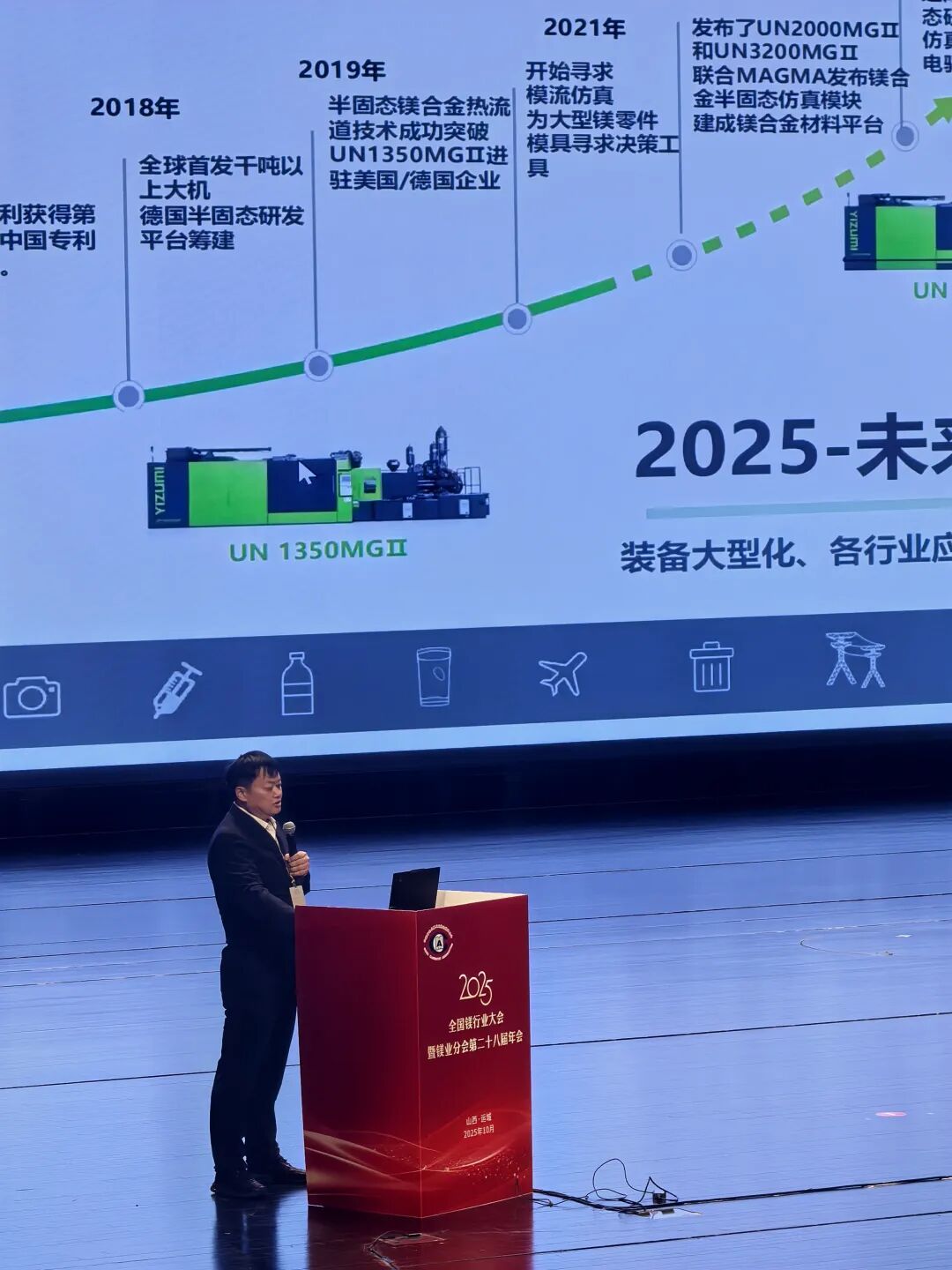

On the morning of the 22nd, Mr. Chen Yong, the market manager for the semi-solid magnesium alloy division of Yizhiming Die Casting Machine, was invited to attend the conference and delivered a presentation titled "Semi-Solid Thick-Walled Magnesium Alloy" in the C Hall of the Yuncheng Convention and Exhibition Center. "Special Report on Solutions and Applications."

In the report, Mr. Chen Yong first presented a new picture of the magnesium alloy industry, detailing the extensive applications of magnesium alloys in various fields such as automotive, sports mobility, and 3C products, with an emphasis on its outstanding advantages of lightweight and abundant reserves.

However, the current magnesium alloy production... The traditional die-casting process, which is heavily relied upon, has numerous drawbacks, such as the need for SF6 gas, excessively high forming temperatures, limited mold lifespan, and poor density. These issues severely hinder the progress of large-scale development of magnesium alloys, making innovative solutions urgently needed in the industry.

Based on this industry background, Mr. Chen Yong introduced Yizhim's thick-walled magnesium alloy. Solution - Semi-solid injection molding technology. This technology cleverly combines the advantages of die casting and injection molding, eliminating the need to prepare semi-solid slurry. By using screw shear to change the morphology of dendritic crystals, it offers numerous advantages, including good density, low energy consumption, no need for a quantitative furnace, as well as improved corrosion resistance and mechanical properties, making it suitable for magnesium alloy forming. A new path has been opened up.

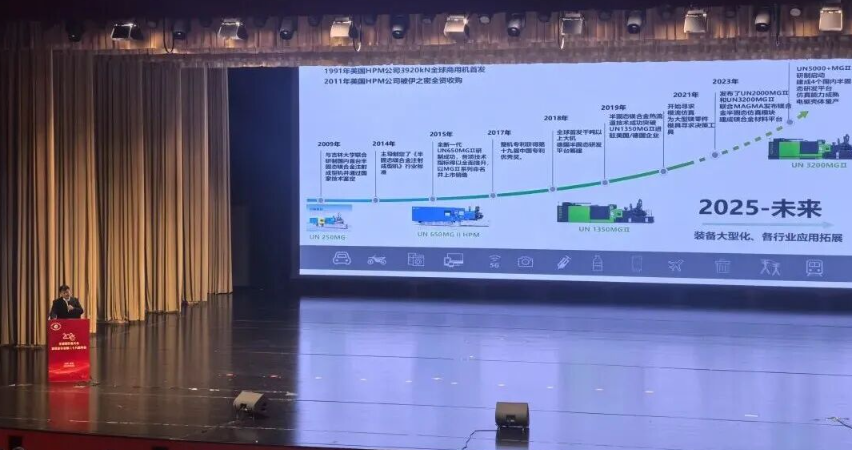

It is worth mentioning that Yizhiming has been deeply engaged in the field of semi-solid magnesium alloy injection molding for a long time, achieving remarkable results. From collaborating with Jilin University to develop the first equipment, to continuously upgrading and launching the MG II series successfully into the market, and recently establishing a research and development platform with the successful delivery of large tonnage models, Yizhiming's technological strength has steadily improved, and its development journey fully demonstrates the company's innovative vitality.

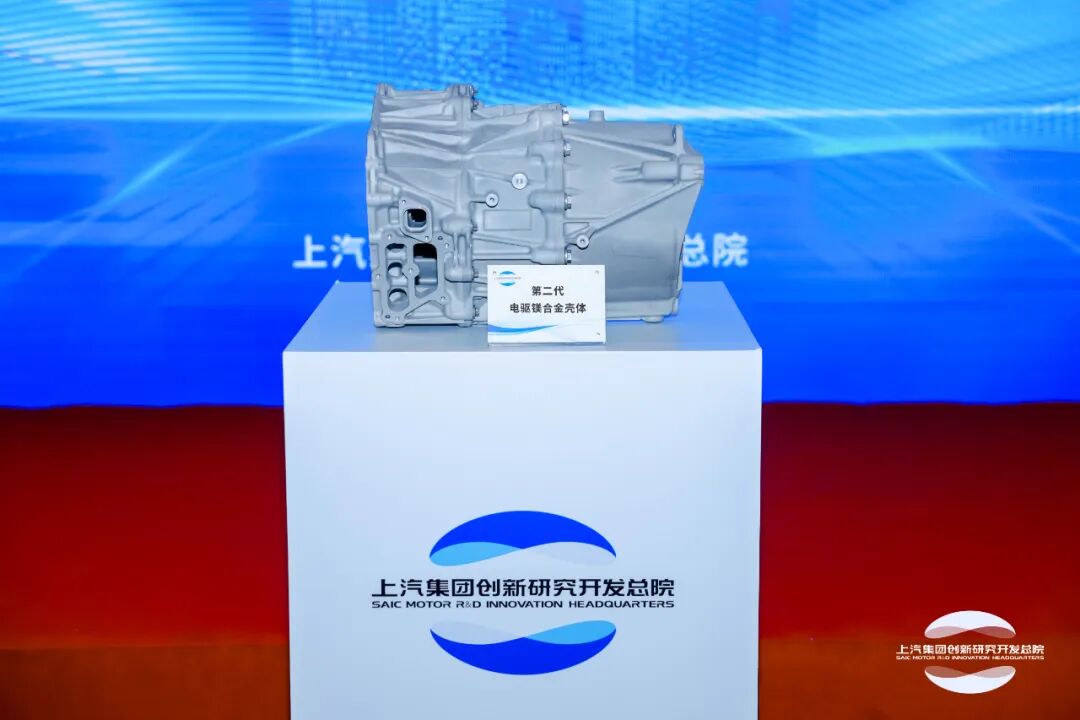

Mr. Chen Yong also shared a successful case of Yizumi, such as undertaking the world's first mass-produced magnesium alloy semi-solid new energy electric drive shell in 2024. This equipment excels in performance aspects such as melting capacity and injection pressure. In addition, Yizumi's unique "Semi-Solid On-Site Butler" service provides comprehensive support to customers, effectively ensuring that they can quickly achieve mass production.

Mr. Chen Yong's report comprehensively showcased Yizhi Mi's technological strength and innovative achievements in the field of magnesium alloy semi-solid thick-walled forming, pointing out new directions for industry development and attracting significant attention from the attendees.

Yizhi Mi is committed to becoming the global leader in the field of semi-solid magnesium alloy forming. In the future, with the continuous growth of market demand for magnesium alloys and the industry's urgent need for high-quality forming technologies, Yizhi Mi, leveraging its deep accumulation and innovative advantages in semi-solid injection molding technology, is sure to continue leading the development trend of magnesium alloy forming technology.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?