An Underrated Link in Twin-Screw Process: Configuration Techniques of the Barrel to Process Optimization

As a core piece of equipment in the production of modified plastics, the design advantage of the twin-screw extruder lies in the flexibility and optimization potential brought by its modular construction.

Most engineers are familiar with optimizing processes by combining different threaded elements, but often overlook the equally important flexibility of barrel configuration.A suitable barrel layout can significantly enhance the mixing effect, reduce energy consumption, and improve product quality stability.

The Importance of Chamber Design

The twin-screw extruder has a fixed configuration that differs from the single-screw extruder and injection molding processes; it employs a segmented barrel design that can be flexibly adjusted according to process requirements.

Through the precise fit between the barrel section and the corresponding screw elements, the twin-screw extruder can achieve a wide range of process specialization, meeting the production needs of various modified plastic products.

In the production of modified plastics, the configuration of the barrel has an impact on...Solid transport, polymer melting, additive mixing, liquid feeding, venting effect.Multiple key process steps.

A rational layout of the mixing cylinder can optimize thermal energy utilization, improve mixing efficiency, reduce material degradation, thereby enhancing product quality and lowering production costs.

Structure Characteristics of Twin Screw Barrel

1 "Figure 8" chamber design

The barrel of the twin-screw extruder has a typical "8" shape cavity, where the two chambers that accommodate the screws intersect but are separated from each other—one screw's flight is almost in contact with the root of the other screw.

This special shape causes the processed plastic to move in a figure-eight path around the conical twin screws in the barrel, increasing the plasticizing time and reducing the friction between the plastic and the barrel screws, thereby ensuring the quality of plasticization and reducing energy consumption.

2 Segmented modular structure

Most manufacturers provide segmented twin-screw barrels, which are composed of four, five, or six separate sections of varying lengths. Each barrel section can be independently heated and cooled to provide precise barrel temperature control.

This modular design allows engineers to build optimized extrusion process components based on the characteristics of the produced compounds, providing great flexibility for the production of various modified plastics.

3 Material and Wear Resistance Treatment

The material selection of the barrel for the twin-screw extruder is crucial for its service life and process stability. Previously, the barrels were made from nitrided steel, and the surface was hardened continuously.

Due to significant wear, the actual production line has now switched to using hard alloys like "miscellaneous chromium" alloy materials to enhance wear resistance.

For high wear areas, such as the side feed port, a replaceable high wear-resistant CPM-10V powder metallurgy steel lining can be used to extend service life.

03 Main Types and Functions of Machine Cylinders

1 Open tube section

The open barrel is a barrel design with external channels to allow the intake or discharge of volatile substances. These open barrels can be divided into several different types:

Feed barrel

The feed barrel is the most basic open barrel, designed with an opening at the top of the barrel through which materials are fed.

The most common position for the feed hopper is at the position of Cylinder 1, which is the first barrel of the process section. Granular materials and free-flowing particles are metered by a feeder and directly fall into the extruder through the feed hopper.

For powder materials with low bulk density, air entrainment can affect flow characteristics. A degassing device can be used, where two open barrels are set at the positions of the first two barrels of the extruder.

The powder is fed into barrel 2 to expel the entrained air from barrel 1, thereby improving the powder feeding efficiency.

Side feeding barrel

The side feeding barrel allows for the addition of additives downstream of the melting zone. In addition to the "8" shaped hole for the extruder screw, there is a second "8" shaped opening on the side of the barrel, allowing the side feeder to be directly connected to the extruder.

A standard open barrel is typically located upstream of the side feeder, serving as a vent to allow entrained air to escape. A more compact design is the rear vent combination barrel, which features a figure-eight hole matching the twin-screw feeder and a small upstream vent.

Exhaust pipe

The open barrel section is also used to discharge volatile vapors generated during the mixing process. The vacuum port is typically located near the end of the extruder and is connected to a vacuum pump to ensure that all entrained volatiles in the polymer melt are removed before passing through the die.

For extruders with at least 10 barrel sections (L/D≥40), placing the venting port on two barrel sections upstream of the die can prevent molten polymer from flowing back into the vent hole, thereby improving operational stability.

When there are high levels of volatiles or diluents injected, additional exhaust ports, including atmospheric exhaust ports and vacuum exhaust ports, can be added along the length of the extruder.

This combination machine cylinder features a rear atmospheric opening and a side feed inlet, providing replaceable high-wear CPM-10V powder metallurgy steel liners in the main process channel and the wear-resistant side feed inlet. Internal water cooling channels can be provided optionally.

(Source: Composite Technologies Inc.)

2 Closed cylinder section

A closed barrel is the most common barrel cross-section design, completely enclosing the polymer melt on all four sides of the extruder, with only one figure-eight opening allowing the screw center to pass through.

Once the polymer and other additives are fully fed into the extruder, the material passes through the conveying section where the polymer is melted and all additives and polymers are mixed. A closed barrel provides temperature control for all sides of the extruder, while an open barrel has fewer heaters and cooling channels.

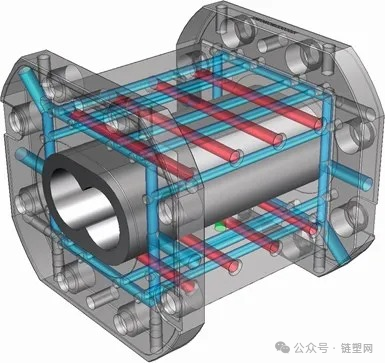

Figure 2 shows the heated (in red) and cooled sections of the closed cylinder.

(Source: Leistritz)

04 Techniques and Strategies for Barrel Configuration

1Typical cylinder assembly sequence

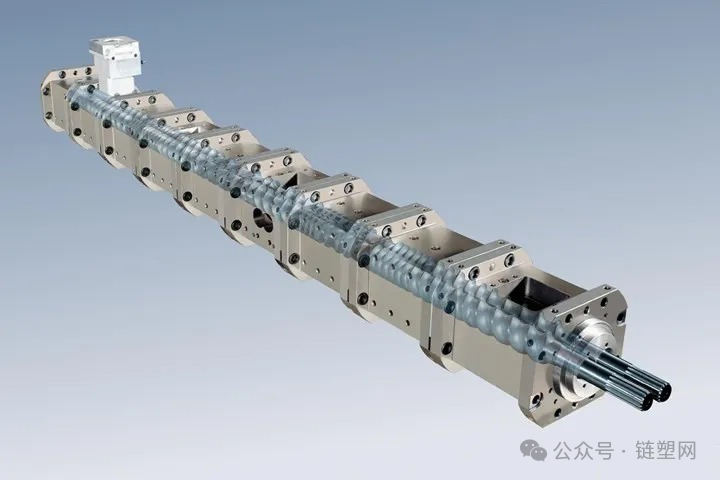

In most mixing systems, the extruder has an open feed section in barrel 1. This feed section is followed by several closed barrels used for conveying solids, melting polymers, and mixing the melted polymers with additives.

The combination barrel can be located at barrel 4 or 5 to allow lateral feed additives, followed by several closed barrels for continued mixing. The vacuum exhaust port is located near the end of the extruder, immediately followed by the last closed barrel before the die head.

Figure 3 Assembly process of the twin-screw compounding extruder. (Source: Leistritz)

2Configuration Based on Process Requirements

The configuration of the machine barrel should be adjusted based on specific process requirements. For example, in the production of glass fiber reinforced modifications, a dedicated glass fiber inlet needs to be set up.

To prevent the glass fiber inlet from being blocked by the polymer melt, short fibers can be introduced using a reverse screw element, while long fibers can be introduced using at least one pair of kneading discs.

The exhaust section should be located downstream of the fiber feed inlet. Near the exhaust port upstream of the exhaust section, sealing screw elements such as reverse-threaded elements or reverse kneading blocks should be installed to prevent particles from being extracted under the action of the vacuum pump.

Special Cylinder Design and Application

1Segmented barrel

The significant feature of the split-type parallel twin-screw extruder is that the barrel can be split, and the screws and the inner liners of the barrel can be freely combined.

The lower cylinder of this design is fixed to the frame, while the upper cylinder is connected to the lower cylinder via a worm gear reducer. When it is necessary to open the cylinder, simply loosen the bolts and turn the handle of the worm gear box to open the cylinder, greatly simplifying the cleaning and maintenance work.

2Conical co-rotating twin-screw barrel

The conical co-rotating twin-screw extruder integrates the technical advantages of both conical counter-rotating and parallel co-rotating twin-screw extruders.

The conical screws rotate in the same direction, causing the processed plastic to form a figure-eight shape around the conical twin screws inside the barrel. This increases the plasticizing time and reduces the friction between the plastic and the barrel screws, thereby ensuring the quality of plasticization and reducing energy consumption.

Tests have proven that this conical co-rotating twin-screw extruder can save more than 30%-50% of energy. It is a novel device suitable for the extrusion granulation and molding of various plastics or rubbers.

For large twin-screw extruders, frequent replacement is not practical due to the significant weight and size of the barrel. However, on a laboratory-scale pilot production line, engineers can continuously adjust the barrel configuration to optimize process parameters before scaling up to production size.

The flexible configuration of the barrel system is the key to the twin-screw extruder's ability to efficiently handle diverse compounding tasks.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory