Application of High-Performance Thermoplastic Composite Rebars in Fuzhou Port Terminal Project

The marine environment is harsh, and traditional marine engineering structures made mainly of reinforced concrete and steel face severe durability challenges, urgently requiring new materials and structures with high durability and long service life. Fiber-reinforced polymer (GFRP) bars can effectively address the corrosion issues of steel bars and steel structures, making them ideal alternative materials for marine engineering. However, their application is limited by the inability to be bent or processed on-site, restricting their engineering applicability. Thermoplastic resin-based composite bars overcome this bottleneck, combining advantages such as multiple re-forming capabilities, high toughness, and excellent durability, perfectly meeting the composite demands of material workability and long-term service in marine engineering.

In the construction of berths 6 and 7 at the Kemen operation area of Fuzhou Port Luoyuan Bay, the owner and the construction unit successfully demonstrated the application of technological achievements obtained from the 2024 project "Performance Research and Demonstration of Thermoplastic Composite Stirrup" by the Harbin Institute of Technology's Non-metallic Materials Innovation Center. The high-performance thermoplastic composite rebars developed in this project enhanced the long-term service performance of the wharf deck and fender structure, providing a good demonstration effect for the large-scale application of thermoplastic composite rebars in wharf engineering.

The harsh marine environment presents severe durability challenges for traditional marine engineering, which primarily relies on reinforced concrete and steel structures. There is an urgent need for new materials and structures with high durability and long lifespan in marine engineering. Thermoplastic resin-based composite bars offer advantages such as reusability, high toughness, and good durability, making them more suitable for marine engineering applications. In the construction of berths 6 and 7 at the Kemen operation area in Luoyuan Bay Port, Fuzhou, the project owners and construction units successfully demonstrated the application of technical achievements obtained from the 2024 project "Performance Research and Demonstration of Thermoplastic Composite Stirrup" by the Non-metallic Material Innovation Center at Harbin Institute of Technology. The high-performance thermoplastic composite bars developed in this project have enhanced the long-term service performance of the wharf surface and fender pile structures, providing an excellent demonstration effect for the large-scale application of thermoplastic composite bars in wharf engineering.

The Komun Operation Berths No. 6 and No. 7 Project at Luoyuan Bay Port Area of Fuzhou Port is located on the southern shore of Luoyuan Bay along the northeastern coast of Fujian Province. It is a key project in Fujian Province for the cultivation of the "Safe, Centennial, Quality Project" demonstration initiative and is identified as an important port area for both container and bulk cargo in the "Overall Plan for Coastal Ports in Fujian Province," as shown in Figure 1.

Figure 1 Geographic Location Map of Luoyuan Bay Port Area, Fuzhou Port

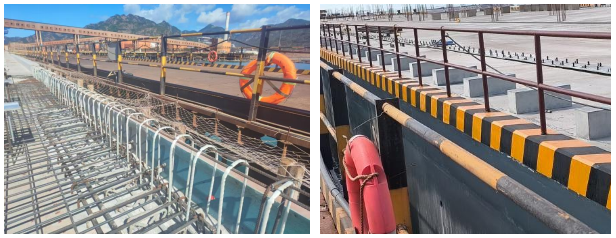

This project selects the wharf deck (Figure 2) and fender structure (Figure 3) as application areas. To address the durability issues of the wharf deck, a deck section 34 meters in length and 12 meters in width is selected, where thermoplastic composite longitudinal bars with a diameter of 12 mm are used to replace steel reinforcement, with a total usage of over 2,000 meters. In addition, to address the durability issues of the fender structure, a 50-meter wharf rear edge section is selected, where thermoplastic composite stirrups with a diameter of 12 mm are used to replace steel reinforcement, with a total usage of over 230 meters.

Thermoplastic composite reinforcement offers advantages such as repeatable molding, high toughness, and excellent durability. By applying high-performance thermoplastic composite longitudinal and stirrup reinforcements, harmful cracks in the main structure panels and wheel-guard concrete structures of the wharf have been prevented, thereby enhancing the long-term durability of the components. The demonstration application of thermoplastic composite reinforcement provides a new approach to addressing the durability challenges of concrete structures in marine environments and will promote the development of marine engineering structures in China toward longer service life.

Figure 2 Demonstration Project Application of Thermoplastic Composite Reinforcement for Dock Panels

Figure 3 Demonstration Project Application of Thermoplastic Composite Reinforcement Quay Fender

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%