Aptyx Expands Precision Extrusion Capabilities Through Acquisition of Argos

AptyxAs a leader in the design, development, and manufacturing of complex devices and components in the life sciences industry, has announced the acquisition of.Argos Company.A precision extrusion company headquartered in Massachusetts. This acquisition has established a new Precision Extrusion Center of Excellence, adding immediate capacity, advanced technology, and in-house engineering expertise to support interventional innovation.

Aptyx President and CEO Gregg Tobin stated, "This marks another milestone in our growth strategy, further enhancing our ability to provide integrated expertise and innovation for our OEM life sciences customers." "This new center perfectly complements our Interventional Excellence Center in Charlotte, where we have a long-standing history of supporting complex transcatheter implants and delivery systems from early design to finished device manufacturing."

Based on Aptyx's advantages in extrusion.

Aptyx, headquartered in Tempe, Arizona, has long been known for its extrusion capabilities, including specialized tubing for sleep, respiratory, and anesthesia applications. The company notes that its new Precision Extrusion Excellence Center builds on this foundation by expanding scale, technology, and catheter-grade precision to support the development and manufacturing of complex interventional systems.

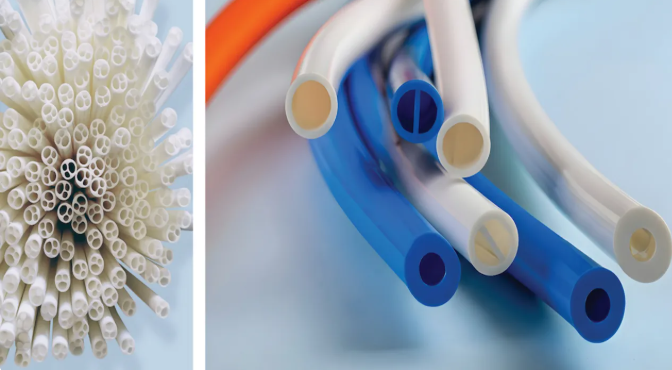

The center will offer customers a variety of features, including high-precision tubing with wall thickness as thin as 0.001 inches and inner/outer diameter tolerances up to 0.0005 inches. According to the company, it will also provide services for rapid development and manufacturing in a controlled environment, internal design tools to enhance speed and precision, as well as a wide range of materials and extrusion techniques. These include multi-lumen tubing, fine tapered tubing, micro-extrusion, co-extrusion, multi-layer extrusion, and balloon tubing.

The facility's close collaboration with customers and commitment to quality will further enhance Aptyx's ability to meet the growing demand in the interventional device market.

Accelerate intervention in market innovation

The company pointed out that the addition of the Precision Extrusion Excellence Center in the Boston area further enhances its ability to serve the interventional and catheter device markets with speed, precision, and scalability. The new facility complements Aptyx's capabilities in molding, extrusion, coating solutions, and finished device assembly.

Patrick Daly, the Global Extrusion Director of Aptyx, said, "We are committed to overcoming technical challenges and advancing the possibilities of medical tubing. This expansion deepens our extrusion expertise and enhances our ability to integrate Aptyx's various strengths to drive advancements in medical technology."

Growth through acquisition

In January 2025, Aptyx announced the acquisition of Medical Murray, based in Charlotte, North Carolina, a company that manufactures catheter-based interventional products and transcatheter implants.

Tobin stated at the time: "This marks an important step in our growth strategy, enhancing our intervention product capabilities and end-to-end offerings, driving innovation, and creating greater value for our OEM life sciences clients. This is a key element of our initial blueprint and the starting point of our evolution, with more developments to come in the future."

Aptyx officials stated that this acquisition will become part of its interventional systems, strengthening the company's interventional and implantable expertise through its engineering talent pool. By collaborating with Medical Murray, Aptyx claims it will be able to provide a complete manufacturing solution for catheter-based interventional and implant products.

About the Company

Aptyx manufactures complex components and devices for the life sciences industry. The company has specialized production facilities in the United States, Canada, Mexico, and China. Formerly known as Molded Devices Inc., the company was renamed Aptyx.

Argos is a custom extrusion company certified to ISO 13485, with over 25 years of experience in small diameter medical tubing and precision thermoplastic profiles. The company specializes in microtubing, liners, co-extrusion, multi-lumen tubing, tapered tubing, and heat shrink products, with expertise in advanced polymers such as TPU, TPE, Pebax, polycarbonate, nylon, polyolefins, PVDF, and other fluoropolymers.

TruArc PartnersA private equity firm focused on middle-market control investments, specializing in professional manufacturing and commercial services. The company collaborates with portfolio management teams to create value through transformative growth strategies.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory