Balancing Strategy – How to Enhance the Toughness of MCA Flame-Retardant Nylon?

To improve the toughness of MCA flame-retardant nylon, the key lies inImprove the dispersion and compatibility of MCA flame retardant in nylon matrix, and optimize the overall composite system.Traditional MCA particles tend to agglomerate in the matrix, "cutting off" the nylon material and significantly reducing its toughness.

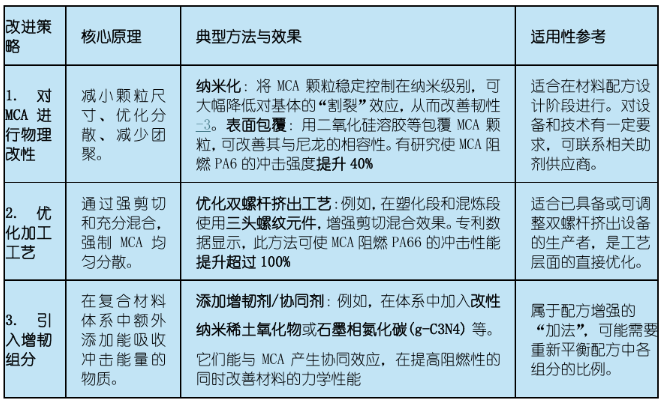

Table: Modification Strategy, Principle, and Effect

Core Ideas and Precautions

When choosing a specific plan, you can refer to the following logic to weigh the pros and cons:

Pursuing comprehensive performance and cutting-edge industry trends. If conditions permit, Nanosizing or surface modification of MCA is currently one of the most effective directions. It can fundamentally solve the aggregation problem and achieve a balance between flame retardancy and toughness.

Focus on process improvement and cost control. : If your focus is on optimizing existing production processes, then Deep optimization twin-screw extrusion process is a cost-effective choice. Significant improvements can be achieved by adjusting the screw configuration and process parameters, often without requiring major changes to the formulation.

Advanced solutions for achieving higher performanceWhen the single method above has limited effectiveness, consider Composite strategy For example,Modified MCA + Optimized Process OrMCA + Nano-Rare Earth/Carbon Material Toughening AgentStudies show that combining MCA with graphitic carbon nitride not only improves flame retardancy efficiency but also leads to better mechanical properties.

Important consensus and premises.

Need to understand a commonly occurring paradox. The addition amount of MCA and the toughness of the material are usually mutually constrained.

To achieve the highest flame retardancy rating for nylon (e.g., UL-94 V-0), a relatively large amount of MCA is often required (for example, PA66 may need more than 6%, and PA6 may need around 12%), which directly leads to a significant decrease in toughness. 2

Therefore, all efforts to improve resilience are aimed at... Minimize the impact on flame retardancy while... , or through more efficient technologies to. Reduce the amount of MCA required to achieve the same flame retardancy rating. 。

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories