Breakthrough Expected in Enzyme-Based Recycling Technology for PET and Nylon 66

Australia’s war on waste has gained a powerful new ally: the Recycling and Clean Energy Commercialisation Hub (REACH) at Deakin University.

REACH has partnered with Samsara Eco to rapidly track the world's first technology capable of recycling plastics and textiles that were previously considered unrecyclable and would take centuries to be eliminated from the environment.

Textile waste is one of the most persistent environmental issues in the world, driven by fast fashion, high consumption, and poor handling practices. In Australia, synthetic fibers such as nylon and polyester account for nearly 60% of clothing materials, but less than 1% of discarded clothing is recycled to make new clothes. Most of it ends up in landfills or is incinerated, increasing pollution and harmful emissions.

Samsara Eco's AI-designed enzymes can break down fossil fuel-derived materials such as synthetic fibers (including nylon 6,6 and polyethylene terephthalate (PET)) into their original monomers, allowing them to be rebuilt into new products with original quality performance.

This collaboration will integrate Samsara Eco with Deakin University's advanced expertise in chemical analysis and polymer processing to better understand and find recycling solutions for specific additives such as dyes, finishing agents, and coatings present in textile waste.

Paul Riley, the founder and CEO of Samsara Eco, said, "We are focused on creating a true loop, which means finding solutions for all plastics. This research supports our efforts to make this a reality. Our enzyme recycling technology has already made significant progress, allowing for the infinite recycling of PET and nylon 6,6 plastics used in clothing and other textiles, including mixed fibers and plastics. Our research collaboration with Deakin University will support us in recycling more waste at a faster pace, larger scale, and with greater precision."

Unlike mechanical recycling, which reduces material quality and limits recyclability, Samsara Eco's enzymatic depolymerization technology can transform worn or contaminated textiles into materials equivalent to the original.

Professor Colin Barrow, Head of the Department of Biotechnology, School of Life and Environmental Sciences, Deakin University, said:

Our research addresses a key challenge in textile recycling—understanding how dyes, textile finishing, coatings, and other chemical treatments affect the degradation and reconstruction of synthetic fibers, including other types of polyester and nylon, for reuse in new products.

We are exploring solutions by analyzing these pollutants and determining their impact on the textile recycling process, in order to enable the production of high-performance recycled materials from all types of waste feedstocks.

Chris Hurren, an associate professor at the Institute for Frontier Materials at Deakin, also participated in the project. He said:

“By testing the performance of these materials in real-world aggregation and processing, we are helping to refine the recycling pipeline, bringing closed-loop textile recycling closer to commercial reality.”

As global pressure increases to reduce emissions and waste in the textile industry, Associate Professor Hurren stated that this technology could potentially revolutionize the industry, bringing both environmental and economic benefits.

We are working to create a scalable, circular future for fashion—a future that reduces reliance on harmful substances and keeps textiles out of landfills.

Samsara Eco has signed a 10-year agreement with global sportswear brand lululemon to support approximately 20% of its total fiber portfolio with recycled materials. This builds on their previous collaboration, which launched the world’s first enzyme-recycled nylon 6,6 garment, recreating their iconic Quickly Top, as well as a limited-edition packable insulated jacket—the first retail garment made from enzyme-recycled polyester.

Samsara Eco's first commercial facility will open later this year in Jerrabomberra, with a 2030 vision to recycle 500 million garments and 10 billion plastic bottles annually, preventing hundreds of thousands of tons of carbon emissions.

Riley said that we have a unique advantage in recycling mixed plastics and fibers. We are utilizing post-industrial and post-consumer waste to create new products and are already helping brands replace virgin inputs with our low-carbon, enzyme-recycled materials, which can be directly integrated into existing supply chains.

Together with researchers from Deakin, we can find further recycling solutions to prevent more waste from being landfilled and entering the circular economy.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

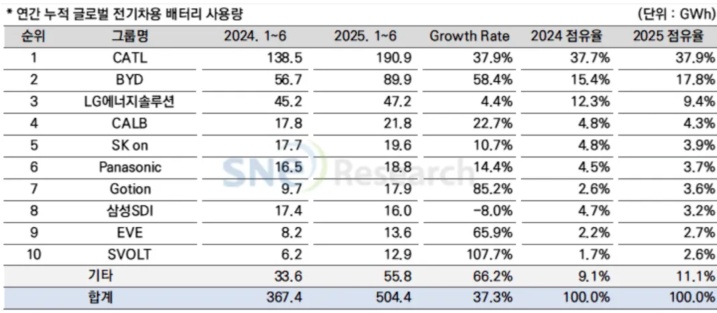

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%