Comparison of Four Screw Configurations: How to Optimize Structure and Feeding Method to Enhance PC/ABS Mechanical Properties

Co-rotating twin-screw extruders are widely used for the modification of polymers - toughening, reinforcing, filling, and reactive extrusion.Compared to single-screw extruders, co-rotating twin-screw extruders have advantages such as better mixing and plasticizing effect, easier feeding, shorter residence time of materials in the screw, and good exhaust performance. However, due to the many operating parameters such as feeding method, feeding amount, and screw configuration, in addition to optimizing product formulas and adjusting process conditions (screw speed, temperature of each heating zone of the screw),The screw combination and feeding method need to be optimized to produce modified plastic products with excellent mechanical properties.。

Polycarbonate (PC)/acrylonitrile-butadiene-styrene (ABS) alloy combines many advantages of both PC and ABS and is widely used in industries such as electronics and electrical, household appliances, communication tools, automobile manufacturing, office machines, and computers.The molecular structure of ABS resin determines its susceptibility to degradation under high temperature or high shear conditions.Especially when forming a PC/ABS alloy through reaction with PC, if the screw combination, length-to-diameter ratio, and process control are not appropriate during processing, it can lead to material degradation, severely affecting the mechanical properties of the PC/ABS alloy, particularly its impact strength. This article studied...The screw combination and feeding method of the twin-screw extruder were analyzed, as well as the impact of adjusting the screw combination and sectional feeding on the mechanical properties of PC/ABS alloys.。

The co-rotating twin-screw extruder often adopts a modular structure, allowing for the free combination of screw elements based on different polymers, formulations, and additive components. Additionally, according to the characteristics of the materials and additives, as well as the conveying, melting, and mixing features, and the mechanical performance requirements of the modified polymers, feeding can be separated at the main feed port of the extruder and the downstream feed port (i.e., the glass fiber feed port) after the plasticizing section. This approach can reduce the specific energy input (i.e., the energy generated per kilogram of material), achieve low-temperature extrusion, minimize heat concentration, and avoid material degradation as much as possible. The screw combination elements used in this work are the conveying elements and kneading block elements at both ends.

Currently, the most commonly used screw elements in co-rotating twin-screw extruders are conveying elements with groove shapes made based on the principle of relative motion, which include forward thread elements and reverse thread elements (see Figure 1).

Figure 1 Schematic of Right-Hand and Left-Hand Threaded Components

This type of threaded component is self-cleaning, open longitudinally and closed laterally, with a strong conveying effect. It has a short material retention time and good self-cleaning properties, allowing for the establishment of high pressure over a short axial distance.To promote melting, establish pressure, enhance mixing effects, increase material residence time, and input shear energy, reverse-threaded elements should be set upstream of the exhaust zone.。

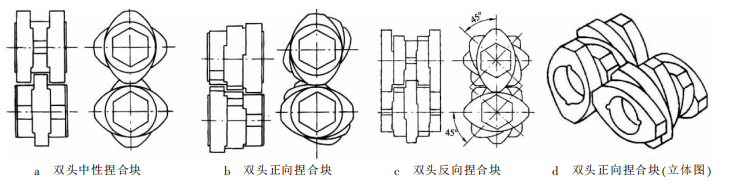

Shearing elements mainly refer to kneading block elements commonly used in co-rotating twin-screw extruders.The main function is to provide high shear, thereby ensuring good dispersive mixing and distributive mixing. Based on the different staggered angles, they can be classified into forward kneading blocks, neutral kneading blocks, and reverse kneading blocks. When the spiral angle formed by the staggered installation of the kneading discs is consistent with the spiral direction of the forward-threaded elements, it is called a forward kneading block. When it is consistent with the spiral direction of the reverse-threaded elements, it is called a reverse kneading block. Kneading blocks with a staggered angle of 90° are called neutral kneading blocks (see Figure 2).

Figure 2 Schematic of Shear Component (Kneading Block)

1

The effect of different screw combinations on the mechanical properties of PC/ABS alloys.

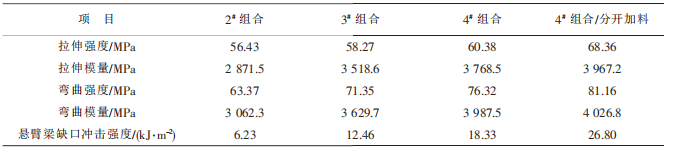

From Tables 1 and 2, it can be seen that the screw combinations have a significant impact on the mechanical properties of PC/ABS alloys. The tensile strength, flexural strength, and notched impact strength of the cantilever beam have all increased significantly, with the increase in notched impact strength being particularly notable. Under the same conditions of PC/ABS alloy formulation and processing, the 4# combination exhibits the best overall performance, followed by the 3# combination, while the 2# combination is slightly lower than the 3# combination. The 1# combination has the worst processing performance and could not be tested.

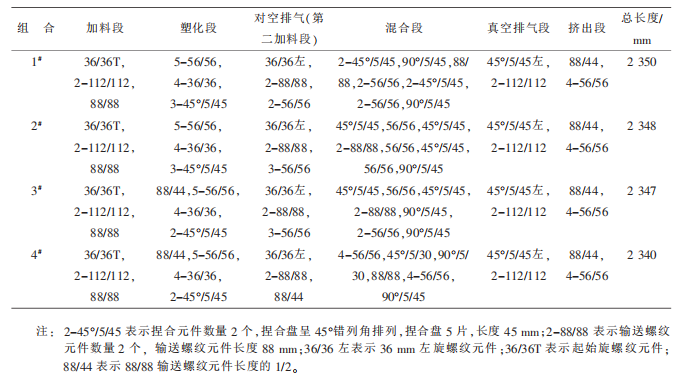

Table 1 Various Screw Combination Forms and Total Lengths

From the extrusion effect: The extrudate at the die of the #1 combination appears as a droplet, which can be drawn after cooling, but the surface is dull and easily breaks, making pelletizing impossible. The extrudate from the #2 combination has a dull surface, occasional breakage, and low mechanical properties. The #3 combination's extrudate has a slightly glossy surface, no breakage, normal pelletizing, and slightly low mechanical properties. The first feeding extrudate from the #4 combination has a smooth surface, no breakage during extrusion, uniform pelletizing, and relatively high mechanical properties. At the vacuum exhaust port in the fourth section, 30% of the total material mass is forcibly added using loss-in-weight metering, resulting in a smooth extrudate surface, no breakage at the die, and high mechanical properties.

Table 2 Effect of Different Screw Combinations and Feeding Methods on the Mechanical Properties of PC/ABS

The main reason for the decline in the mechanical properties of materials caused by the 1#~3# combination is the pursuit of dispersed and distributed mixing effects, which increased the number of kneading blocks and overlooked the impact of the large length-to-diameter ratio and high shear strength of the screw on the performance of PC/ABS alloys. Since the flow characteristics of PC/ABS alloys are non-Newtonian fluids, their melt viscosity is related to processing temperature and shear rate, but is more sensitive to shear rate. Therefore, this work made significant adjustments to the 4# combination, reducing one 45° kneading block in the plasticizing section, replacing thick kneading block elements with two thin kneading block elements in the mixing section, and reducing the number of kneading block elements to form an appropriate screw combination, significantly improving the mechanical properties of the PC/ABS alloy.

2

The effect of additive methods on the mechanical properties of PC/ABS.

PC/ABS alloy is extremely sensitive to the shear stress and shear rate of the screw. Despite optimizing the screw combination and reducing the kneading disc elements, the large length-to-diameter ratio of the screw leads to prolonged residence time of the material within the screw, causing multiple compressions, backflows, stretches, and shears that result in a decline in the mechanical properties of the material. In this work, a loss-in-weight feeder was set up at the downstream glass fiber feeding port to quantitatively add 30% of the total material mass of the PC/ABS mixture. This portion of the material experiences reduced shear and residence time in the screw by one-third, thereby decreasing the likelihood of the decline in mechanical properties caused by excessive shear and prolonged residence time in the screw, and significantly improving the mechanical properties of the PC/ABS alloy.

From Table 2, it can be seen that the mechanical properties of the PC/ABS alloy produced by the separate feeding method in the 4# combination have improved. The tensile strength and flexural strength increased from the original 56.43 and 63.37 MPa to 68.36 and 81.16 MPa, respectively. The cantilever beam notch impact strength increased from the original 6.23 MPa to 26.80 MPa. The materials produced using an appropriate screw combination and feeding method can meet the requirements of domestic and international home appliance enterprises. Moreover, this feeding method and optimized screw combination significantly enhance the mechanical properties of toughened ABS, filled modified ABS, glass fiber reinforced modified ABS, flame-retardant modified ABS, and flame-retardant PC/ABS, meeting user demands.

The suitable processing screw for PC/ABS alloy has moderate shear force, good plasticizing effect, and uniform distribution of toughening agents.

The screw combination of a co-rotating twin-screw extruder significantly affects the mechanical properties of PC/ABS alloy. By adopting a reasonable screw combination, modified engineering plastics with excellent mechanical properties can be obtained.

Using stepwise feeding can achieve a higher extrusion rate, reduce the residence time of the material in the screw, lower the shear rate, and achieve low-temperature extrusion, effectively improving the mechanical properties of modified engineering plastics.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories