Coperion Twin-Screw Extrusion Granulation System: The High-Efficiency Engine Driving Mechanical Plastic Recycling

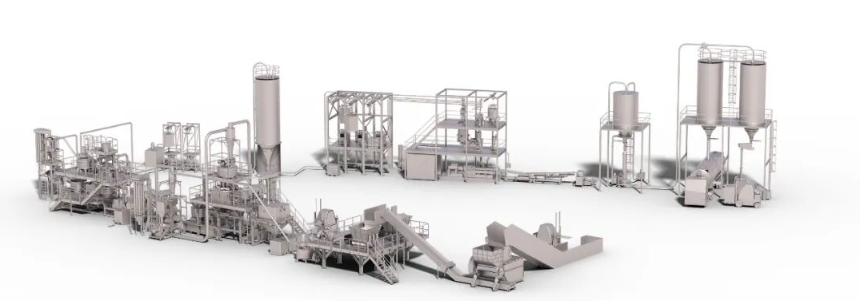

After consumptionFrom PET bottles to polyolefin daily miscellaneous materials, and from complex multilayer composite films to industrial edge scraps, Coperion's innovative twin-screw extrusion solutions continuously break through the boundaries of efficiency and quality in mechanical plastic recycling. In the face of increasing global plastic pollution and resource scarcity, Coperion provides mature and reliable technology to achieve sustainable, large-scale, and high-value plastic recycling.

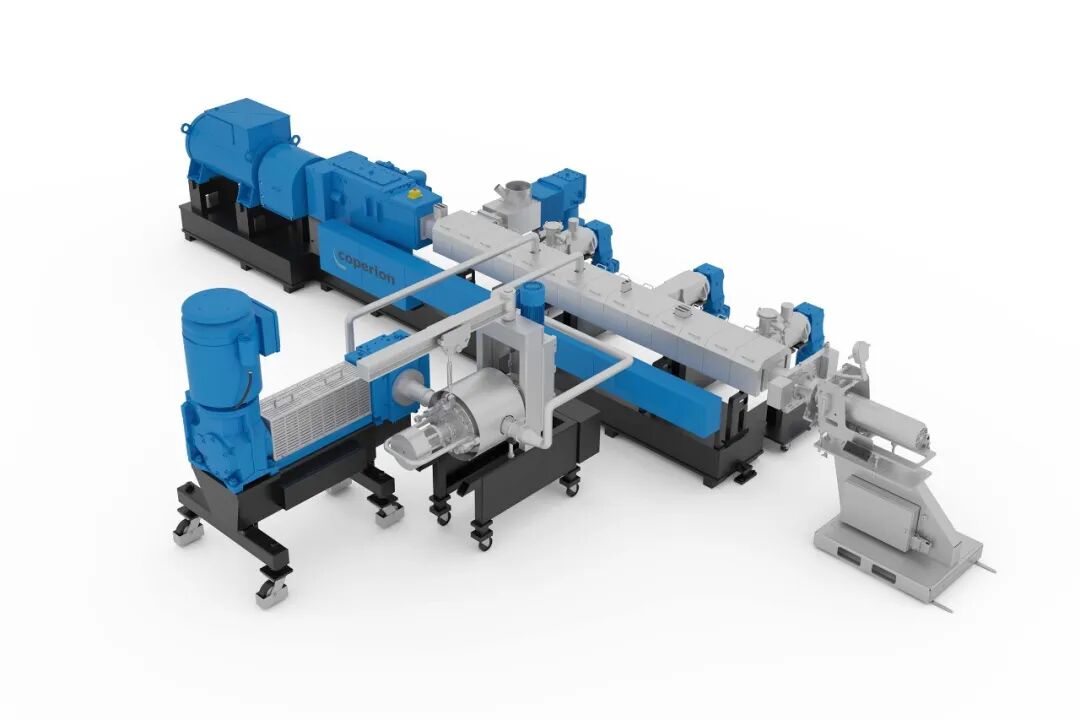

In today's environment, the demand for advanced recycling solutions has never been more urgent. Landfills are overflowing, oceans are polluted with plastic, and regulatory frameworks are becoming increasingly stringent. The challenge lies in efficiently recycling plastics while ensuring the highest standards of purity, safety, and performance. Coperion's twin screw extruders, especially the ZSK series, are designed to meet these demands. Their unique structure provides exceptional mixing, devolatilization, and process control, making them the ideal choice for processing contaminated, complex, and large-volume waste. With decades of process expertise and continuous innovation, Coperion's solutions help recyclers produce high-quality materials that meet market and regulatory requirements.

PET Bottle-to-Bottle Recycling: A Benchmark for Food-Grade Circularity

The recycling of PET bottles into food-grade recycled PET (rPET) reflects the principles of a closed-loop cycle. This process demands the highest levels of purity, consistency, and safety. Coperion offers a complete integrated solution centered around the ZSK twin-screw extruder, seamlessly combining washing, drying, extrusion, and pelletizing processes. The co-rotating design of the ZSK extruder ensures excellent self-cleaning capabilities, preventing polymers from staying in the extruder for extended periods and undergoing thermal degradation, which avoids yellowing and black specks while ensuring product quality. The resulting recycled PET pellets exhibit outstanding intrinsic color and batch consistency, meeting the stringent standards of brands and regulators.

The key advantage of this technology is the high-performance devolatilization efficiency of the twin-screw extruder, supported by a specially designed vacuum system. The device efficiently removes residual volatile contaminants (such as monomers and impurities) while minimizing viscosity loss, which is crucial for maintaining the mechanical properties of recycled PET. Importantly, this process eliminates the need for pre-drying, significantly reducing energy consumption by up to 30% and improving overall process economics and environmental footprint.

As global demand for recycled PET continues to grow, the single-machine capacity for PET bottle-to-bottle recycling and pelletizing has expanded from 1-2 tons per hour to over 9 tons. Coperion's modular, scalable plant design supports this growth with large-scale, highly integrated production facilities to meet the increasing market demand.

The commercial success of Kebelon's PET recycling solution has been reinforced by comprehensive regulatory approvals. Kebelon's food-grade recycling production line has been approved by the European EFSA and the US FDA, and the produced rPET pellets have been certified by leading global beverage brands for use in their packaging. These certifications open the door to high-value markets, enabling recyclers to provide safe, high-quality recycled materials for food contact applications.

Post-consumer rigid polyolefin recycling: From municipal waste to food-grade resin

Recycling post-consumer rigid polyolefins, such as domestic waste, faces significant challenges. These materials are often heavily contaminated and carry stubborn odors, making it difficult to process them into high-quality, food-contact-grade resins. Traditional recycling methods often fail to meet the stringent purity and safety standards required for such applications.

Kebelong has developed a comprehensive and integrated solution that systematically overcomes these obstacles. The process begins with preprocessing steps of crushing, cleaning, and drying to remove surface contaminants and odors. The resulting flakes are stored in controlled silos before entering the core process.In the ZSK twin-screw extruder, the material is melted, filtered with high precision, and subjected to multi-stage vacuum degassing. This process effectively reduces VOCs and odors, and can be optionally equipped with additional degassing agents to further enhance removal efficiency. For applications requiring higher purity, the Coperion ZS-EG side degassing unit handles large amounts of volatiles, ensuring maximum removal capability and product purity.

Downstream, Kebelong provides the EcoFresh pellet silo deodorization system, which eliminates residual odors, including long-chain molecules that have migrated into the polymer matrix. These systems can be flexibly configured, such as a dual-silo layout with separate heating and cooling, or a compact single-silo layout with integrated heat exchangers to save space and simplify operation. The resulting pellets are close to virgin quality and are suitable for high-value applications such as food packaging, medical devices, and premium consumer goods.

This integrated approach not only produces high-quality recycled materials but also supports sustainable development goals by reducing reliance on virgin plastics, minimizing environmental impact, and enabling recyclers to confidently enter new markets.

PCR Upgrade Recycling: ZSK FilCo Technology Achieves True Upcycling of PCR Plastics

Conventional recycling often leads to downcycling, where recycled plastics are used in low-value applications, limiting their economic and environmental benefits.The ZSK FilCo filter- mixing-modification integrated machine breaks this model, achieving true upgraded recycling—adding value to post-consumer recycled plastics and producing materials suitable for demanding, high-performance applications.

The ZSK FilCo filtering and compounding system simultaneously completes filtering and compounding modification in a single integrated process. For heavily contaminated PCR material streams, it removes impurities while simultaneously adding functional components such as talc, glass fibers, or other additives. This method effectively rewrites the recycling pathway, eliminating multiple remelting, refiltering, and recompounding steps, reducing thermal stress, energy consumption, and polymer degradation. The result is high-quality, high-performance recycled material obtained in a single thermal process, possessing excellent mechanical, aesthetic, and functional properties.

Compared to traditional two-step methods, the ZSK FilCo system reduces energy consumption and emissions by over 50%. Its twin-screw extrusion technology ensures faster and more uniform energy transfer, and the process does not require re-melting, ensuring consistent quality. This enables recyclers to produce high-value materials suitable for automotive, technology, and packaging applications, opening up new revenue streams and supporting sustainable development.

Multilayer composite film recycling: Closed-loop system for high-value recycling of scraps

Multilayer composite films are widely used in packaging due to their barrier properties and multifunctionality. However, their complex multilayer structure and irregular geometric shapes generate a large amount of clean edge trimmings, making it difficult to efficiently recycle online without compromising the quality of the films. Traditional methods often require pre-compaction or agglomeration, which increases cost and complexity.

The Coperion closed-loop recycling system addresses these challenges by directly reusing shredded scraps in the production process. The scraps are shredded and metered into the process through a loss-in-weight belt feeder.ZSK Mc18Twin-screw extruder. The extruder's dispersive and distributive mixing capabilities fully homogenize polymer melts and ensure complete degassing, even when faced with complex multi-layer formulations. The resulting recycled material can replace virgin resin in the PE layer without affecting film performance, achieving high ratio and high-value closed-loop recycling.

To further improve yield and process reliability, Coperion has developed the ZS-B MEGAfeed side feeder, specifically designed to handle fluffy, bulky regrind materials. This innovative feeding system reliably processes large quantities of material, eliminating bottlenecks caused by bridging and feeding instability, and significantly reducing capital and operating costs. By removing the need for pre-compaction or agglomeration, the system makes the online recycling of complex multi-layer films economically feasible and environmentally sustainable.

Actual data proves the effectiveness of this method, using ZSK 58 Mc.18The output of the twin-screw extruder for multi-layer film recycling has increased from approximately 160 kg/h to 1,400 kg/h. These improvements significantly boost productivity and profitability while maintaining high-quality output suitable for demanding applications.

Solvent Method and Volatile Removal Technology: Innovative Pathways for High-Quality Mechanical Recycling

Complex multi-layer composite materials such asPA/PE films have traditionally been considered unrecyclable through conventional mechanical methods due to their layered structure and degree of contamination. Chemical recycling offers an alternative solution, but it generally involves high energy consumption and cost.

Kebron has collaborated with APK to develop the Newcycling® solvent-based process, which enables the mechanical separation of polymers without chemical degradation. This process includes crushing, sorting, and selectively dissolving PE in a solvent, leaving PA as a solid. The solid-liquid separation allows for the individual processing of each polymer, avoiding the high energy consumption and environmental impact associated with chemical recycling. By processing polymers in solution, contaminants can be removed more effectively through filtration, followed by devolatilization in a ZSK twin-screw extruder to efficiently eliminate residual solvents, ensuring that the final pellets meet strict quality and safety standards.

The multi-stage devolatilization exhaust port combined with a specialized screw configuration enables the phased removal of volatile components, producing pellets close to virgin quality suitable for high-value applications. This innovative approach allows for the recycling of previously thought non-mechanically recyclable multilayer packaging, opening new pathways for sustainable material recovery and high-value reutilization.

Kebilon Recycling Innovation Center: From Laboratory to Industrial Scale

To meet the growing demand for advanced recycling solutions, KOBELO has established a dedicated Recycling Innovation Center in Weingarten, Germany. The facility is equipped with a modular pilot recycling line that can simulate a wide range of production scenarios, from simple to highly complex. Customers work closely with KOBELO experts to develop, test, and validate new recycling processes, ensuring that the solutions are technically feasible, economically viable, and scalable for industrial deployment.

The flexibility of the Recycling Innovation Center enables it to quickly adapt to different raw materials, process configurations, and product requirements. This collaborative approach accelerates innovation, reduces risk, and shortens the time to market for new technologies. It also provides a platform for testing emerging materials, optimizing process parameters, and perfecting equipment design, ensuring that Coperion solutions remain at the forefront of the industry.

Conclusion: Empowering a true circular economy

Keblon's twin-screw extrusion technology continues to lead the forefront of mechanical plastic recycling. Whether it is to meet food-grade standards...rPET's stringent color and safety standards enhance the value of post-consumer polyolefins while achieving a closed loop for complex multi-layer composite films. Kebelon is always committed to technological innovation and excellence.

Its solutions enable recyclers to produce high-quality, high-value materials that meet market demands while supporting environmental sustainability. As the global recycled plastic market continues to grow, Cabot's comprehensive product portfolio and specialized support infrastructure make it a key driver of a true circular economy. By transforming waste into valuable resources, Cabot makes sustainable plastic recycling a viable and scalable reality, helping to shape a resilient, environmentally responsible, and economically sustainable future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory