Dazzle laser's green laser metal 3d printing core equipment to debut at shenzhen formnext exhibition

Han's Laser powers up metal 3D printing again, Han's Laser will showcase core equipment including green laser metal machines at the Shenzhen Formnext exhibition.

August 26-28, 2025, Shenzhen International 3D Printing and Additive ManufacturingThe Manufacturing Exhibition (referred to as "Shenzhen Formnext") will grandly open at the Shenzhen World Exhibition & Convention Center (Bao'an Hall)! As a deep cultivator and innovative force in the field of additive manufacturing, Han's Laser Additive Manufacturing is ready and fully prepared to showcase several core devices at the exhibition.

Product Features:

Safe, stable, and efficient

2. Upper powder feeding, bidirectional efficient variable-speed powder laying

Small light spots, suitable for printing high-precision parts.

4. Equipped with intelligent powder spreading and real-time process monitoring module

Green laser light is suitable for high-reflectivity and refractory metal materials such as copper, aluminum, and tungsten.

Application areas:

Applicable to industries such as radiators, 3C, new energy vehicles, and aerospace.

Material applicability

The M360G green laser printing equipment demonstrates excellent adaptability to highly reflective metals such as copper, gold, and aluminum, making the printing process for these materials more convenient and efficient, while also providing an outstanding solution for processing high-reflectivity materials. In addition, green laser energy can also be more effectively applied to refractory metals such as tungsten, tantalum, molybdenum, zirconium, niobium, and chromium, resulting in superior forming performance.

Product Features:

1. Optional dual galvanometer.

2. Four-laser system for efficient printing

3. Optional configuration with intelligent monitoring and grafting printing function module.

4. Full open process parameter package for easy secondary development.

Product Application:

Suitable for industries such as prototyping, shoe molds, 3C, and automotive.

Mold Industry:

3D printing in the mold industry reduces the production cycle of molds and lowers manufacturing costs.

Automotive industry:

Optimizing structural design can significantly reduce vehicle weight and fuel consumption; research and trial production do not require mold opening, shortening the vehicle development cycle; mass production can achieve digital manufacturing without the need for tooling and fixtures.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

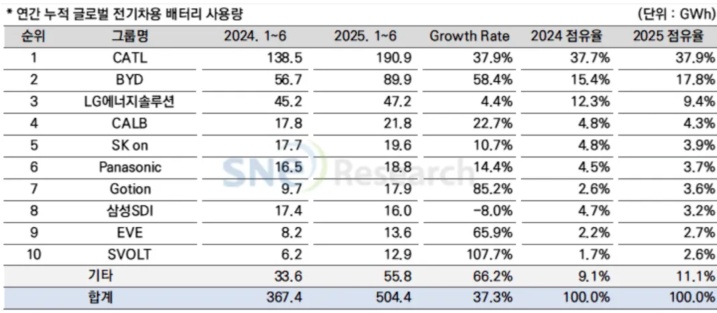

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%