Essential knowledge for modified r&d engineers: Understanding the Nylon Family and Application Material Selection Challenges

In the plastics industry, who hasn't dealt with nylon? However, when it comes to the complex lineage and selection methods of the nylon family, even many seasoned professionals might scratch their heads. Today, let's take a closer look at this familiar yet mysterious material family.

01

Nylon family

When nylon is mentioned, many people's first reaction is PA6 and PA66. Indeed, these two are the "pillars" of the family, with high production volume and wide applications, ranging from gears and bearings to electrical housings, they can be seen everywhere.High absorbency rateThis old problem also causes them toPrecision parts struggle to "lift their heads" in humid environments.。

In the family, there is also a group of "low-key powerhouses"—Long carbon chain nylon, such as PA610, PA612, PA12These have longer molecular chains, lower amide bond density, and naturally reduced water absorption. Good dimensional stability, hydrolysis resistance, and excellent flexibility are their common characteristics, making them particularly suitable for manufacturing.Fuel lines, brake hoses, premium toothbrush bristlesThese are "particular activities."

02

Special Nylon Classification

High-temperature nylon (semi-aromatic nylon))

PA6T、PA9T、PPAThese names are "golden brands" in high-temperature applications. They have introduced aromatic ring structures into their molecular chains.The heat distortion temperature easily exceeds 280°C, and the long-term use temperature is above 150-200°C.It is the best choice for engine peripheral components, SMT connectors, and water pump impellers.

Transparent nylon

Who says nylon is always opaque? By introducing special monomers or copolymers that disrupt the orderly arrangement of molecular chains, we can achieve transparent nylon with a light transmittance close to 90%. It possesses the toughness of nylon, the transparency similar to PC, and is more resistant to scratches and chemical corrosion.High-end goggles, instrument windows, food containersIt is its stage.

Super-tough nylon

This is the perfect "alloy" of nylon and elastomer. Through special compatibility technology (such as reactive extrusion), the elastomer is dispersed into the nylon matrix in extremely fine particles. Normally hard and strong, when subjected to severe impact, these elastomer particles can effectively initiate and terminate crazing, **absorbing a large amount of impact energy**, preventing material breakage. **Power tool housings, sports safety equipment, and automotive collision parts** all rely on it.

Bio-based nylon

This is the "green noble" of the nylon family.Monomers are produced from renewable biomass (such as castor oil, corn sugar) through bio-fermentation, and then polymerized into PA11, PA1010, PA510, etc.It not only reduces carbon emissions at the source, but also offers superior performance in certain aspects (such as low water absorption and heat resistance).Automotive lightweighting, high-end textiles, consumer electronics, and other environmentally conscious fields.The prospects are broad.

03

Practical Material Selection Guide

Faced with so many options, how do you choose? Remember the following process to help you quickly target your goal:

Step 1: Set the threshold according to the environment

High temperature (>120-150°C) → First choiceHigh-temperature nylon(PPA/PA9T)

Moisture/need dimensional stability → Prefer long-chain nylon (PA12/PA612)

Need transparency → Can only choose transparent nylon

Exposure to oil and chemicals →Long carbon chain nylon or specific high-temperature nylon

Step 2: Balance according to performance

Once the threshold is crossed, consider whether you need rigidity or flexibility.

Be rigid.Select fiberglass reinforced version.For resilience, chooseSuper-tough or flexible long carbon chain nylonAdditionally, processing properties need to be considered, such as thin-walled parts may require grades with better fluidity.

Step 3: Consider Cost and Added Value

Under the premise of meeting the requirements, modified PA6/PA66 material is always the king of cost-effectiveness.

If the product has environmental protection and brand promotion needs,Bio-based nylonCan bring additional value.

Small batch, large complex parts can be evaluated.MC cast nylonWhether it is more cost-effective.

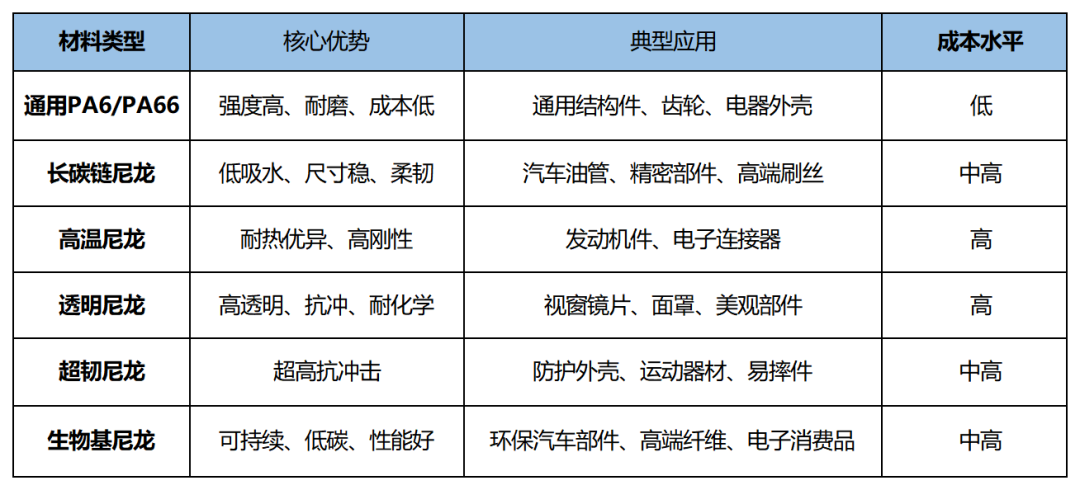

Here is a simple comparison table for better visualization:

04

Future Direction

The future development of nylon has two clear main lines:

Continuous Performance BreakthroughBy using alloys, composites, and nanotechnology, materials are made stronger, more heat-resistant, and more stable.

Second, the trend towards greening is irreversible. The production capacity and variety of bio-based nylon will continue to increase, and the chemical recycling technology of traditional nylon will also mature.Implement a green closed loop for the entire lifecycle.。

The story of the nylon family is an innovative journey from meeting basic needs to creating infinite possibilities. From clothing stockings to high-precision components that reach the skies and seas, it continually pushes its own boundaries. As engineers and practitioners, understanding the "temperament" and "specialties" of this family is essential to maximize its value in products.

Next time you face the challenge of material selection, try drawing a triangle of environment, performance, and cost; the answer may become clearer. In this era where materials define products.Understanding materials is the key to innovation.。

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories