Eu proposes listing tbph in pops regulation: What Does the Future Hold for Brominated Flame Retardants?

The EU has proposed listing TBPH (tetrabromophthalate) in Annex A (Elimination) of the Stockholm Convention on Persistent Organic Pollutants (POPs), which is undoubtedly a significant bombshell for the brominated flame retardant market, signaling that the industry will undergo profound changes. Here are the possible future development paths and key impacts for brominated flame retardants:

Core Use Prohibition:Once officially listed in Annex A of the POPs Regulation, the production, use (including use in articles), and placing on the market of TBPH in the EU will be completely prohibited, with only a very limited number of specific exemptions (usually with time restrictions) allowed.

Global Impact Diffusion:The Stockholm Convention is an international treaty. Once the EU's proposal is adopted by the Conference of the Parties to the Convention, it will require all parties worldwide to take action to phase out TBPH. This will significantly shrink the global market for TBPH.

Urgency:Relevant industries (especially those using TBPH in foam plastics, textiles, electronics, and appliances) must immediately begin seeking alternatives and adjust their production processes. The phase-out schedule may be relatively tight.

Regulatory pressure continues to escalate.TBPH being listed in the POPs list is the latest example of the increasingly stringent regulations faced by brominated flame retardants, especially traditional or certain specific new brominated flame retardants. Previously, polybrominated diphenyl ethers (such as Penta-, Octa-, DecaBDE) and hexabromocyclododecane (HBCDD) have been listed as POPs or subject to strict restrictions.

"Policy drive for sustainable chemicals"The EU's Chemicals Strategy for Sustainability (CSS) and the REACH regulation continue to promote the phase-out of substances with hazardous properties such as PBT (persistent, bioaccumulative, toxic), vPvB (very persistent, very bioaccumulative), or CMR (carcinogenic, mutagenic, reproductive toxicity). Many brominated flame retardants are key regulatory targets due to these characteristics.

Environmental and health concerns dominate:The persistence, bioaccumulation, long-range transport potential of brominated flame retardants in the environment, and their potential toxicity to wildlife and humans (including endocrine disruption, neurodevelopmental effects, etc.) are the core drivers of regulatory actions. Public and NGO concerns also continue to exert pressure.

Market confidence is frustrated.The ongoing bans in major markets (especially the EU) will undermine the overall confidence of downstream users (such as brand owners and manufacturers) in brominated flame retardants. They are concerned about supply chain disruptions and future compliance risks, which accelerates their search for alternatives.

Brominated flame retardants will not completely disappear, but their future will show significant differentiation.

Partial phase-out of brominated flame retardants:Traditional or certain specific novel brominated flame retardants like TBPH, which are identified as POPs or have significant PBT/vPvB/CMR characteristics and lack effective risk management, will see their market drastically shrink until they are phased out.

"Survival Space for 'More Sustainable' Brominated Flame Retardants (But Pressure Remains Unabated)"

Aggregate brominated flame retardant.High molecular weight makes it difficult to migrate out of materials, resulting in a relatively low risk of being absorbed and accumulated by organisms (such as brominated polystyrene, brominated epoxy resins, polybrominated styrene-butadiene block copolymers, etc.). They currently face less direct regulatory pressure compared to small molecule flame retardants, but they still need to continuously demonstrate their environmental friendliness and safety.

Reactive brominated flame retardant:By chemically bonding to the polymer backbone, it is not easily leached out and is theoretically safer. However, its range of applications is relatively limited.

Key Points: Translate the above content into English and output the translation directly without any explanation.Even for polymeric or reactive types, more comprehensive environmental, health, and safety (EHS) assessments are needed to meet increasingly stringent regulatory requirements (such as the EU's PFAS restriction proposal, which may also affect certain fluorinated brominated flame retardants) and to demonstrate their advantages throughout the entire lifecycle.

Innovative research and development focusing on safety:Flame retardant manufacturers will invest more resources in developing a new generation of brominated flame retardants, with the core objective being:

Significantly reduce or eliminate PBT/vPvB properties.

Reduce ecological toxicity and human health risks.

Increase molecular stability to prevent degradation into toxic products.

Improve compatibility with polymers and reduce migration.

While maintaining excellent flame retardant efficiency.

The phase-out of TBPH will further drive the market shift towards non-halogenated flame retardants.

Phosphorus-based flame retardant:Inorganic phosphorus (such as ammonium polyphosphate APP), organic phosphorus (such as phosphate esters, phosphonate esters, hypophosphites), and their nitrogen synergistic systems are currently the main alternative directions, widely used in engineering plastics, polyurethane foams, textiles, etc.

Nitrogen-based flame retardant:Melamine and its derivatives (cyanurates) are commonly used in conjunction with phosphorus compounds.

Inorganic flame retardant:Aluminum hydroxide (ATH) and magnesium hydroxide (MDH) are widely used in fields such as wires and cables, and building materials. However, high filler content may affect material performance. Nanotechnology may bring performance improvements.

Silicone-based flame retardant:Silicone, silicone resin, etc., can form an insulating and oxygen-barrier carbon layer and are environmentally friendly, but the cost is relatively high.

Intumescent flame retardant:Combined with carbon sources, acid sources, and gas sources, it efficiently uses an expanded carbon layer barrier and is commonly used in polyolefins, coatings, etc.

Bio-based flame retardant:The development of flame retardants using biomass resources such as phytic acid, chitosan, and lignin is an important research direction for future sustainable development.

Acceleration of Substitution Transition:Downstream users should immediately assess the use of TBPH in their supply chains, work closely with flame retardant suppliers, and test and validate feasible alternatives (brominated or non-halogenated).

Investment in R&D:Flame retardant manufacturers need to heavily invest in developing safer and more efficient brominated flame retardants, as well as superior-performing non-halogen alternatives.

Lifecycle assessment:Whether choosing new brominated flame retardants or non-halogen alternatives, a comprehensive environmental and health safety assessment is required to avoid "regrettable substitution" (replacing one problematic substance with another problematic substance).

Balancing the improvement of flame retardancy and material performance:Alternatives often require higher addition levels to achieve the same flame retardant grade, which may affect the mechanical properties, processing performance, and cost of materials. Developing synergistic enhancement technologies and surface modification technologies is crucial.

Focus on the circular economy:When selecting flame retardants, it is necessary to consider the compatibility with material recycling to avoid hindering the development of the plastic circular economy.

The EU proposes to list TBPH in the POPs regulation, which is another clear signal that brominated flame retardants are facing a severe regulatory environment.The future of brominated flame retardants is bound to be a transformation of "being born towards death."Some high-risk products (such as TBPH) will come to an end; some "more sustainable" brominated products (mainly polymeric types) may retain a place in certain application fields, provided they continuously prove their safety. However, the overall market space will remain under pressure.The mainstream trend and future of the industry lie in the innovation and application expansion of halogen-free flame retardants, as well as the development of inherently safer new-generation flame retardant technologies.Enterprises must actively embrace change, accelerate research and development, and pursue alternative transformations in order to survive and thrive amidst increasingly stringent environmental regulations and market demands. The "golden era" of brominated flame retardants is over, and future competition will focus on balancing environmental friendliness, safety, and overall performance.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

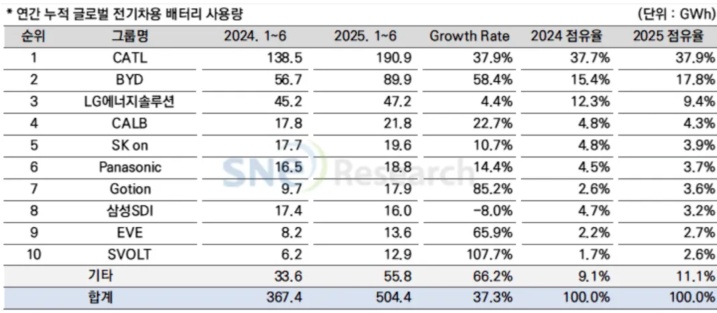

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%