Experience sharing: Excess CaZn Stabilizer Can Cause PVC Scorching?

In PVC processing, calcium-zinc stabilizers are widely used as an environmentally friendly heat stabilizer. However, the dosage is not a case of "the more, the better." Exceeding the optimal range can actually lead to scorching of the product (commonly known as...). Zinc Fume Fever Overstabilized burning Calcium zinc stabilizers turn yellow after use? And suddenly a "zinc burn" black screen? What's the reason? The mechanism mainly stems from the interaction of the following four levels:

I. Chemical Degradation Promotion: The "Anti-Catalytic" Effect of Stabilizers Themselves

Metal soaps (especially zinc stearate) in calcium-zinc composite stabilizers decompose at high temperatures, generating acidic byproducts and free acids. When added in excess:

Catalytic Degradation of Zinc Soaps Excess zinc soaps can react with HCl produced from PVC degradation to form zinc chloride (ZnCl₂). ZnCl₂ is an extremely strong Lewis acid catalyst that significantly accelerates the dehydrochlorination of PVC molecular chains, leading to rapid polymer degradation and discoloration (yellowing → blackening), a phenomenon known as "zinc burning".

Acid-catalyzed cycle The liberated free acids and acidic by-products from decomposition further catalyze degradation, forming a vicious cycle that cannot be suppressed even with the presence of auxiliary stabilizing components like calcium soaps.

II. Process Out of Control: Lubrication System and Thermomechanical Balance Disrupted

Calcium-zinc stabilizers often possess lubricating properties, and excessive addition can interfere with the entire lubrication system.

Plasticization and shear imbalance Excessive lubrication causes material slippage in plasticizing equipment (such as screws), resulting in insufficient shear heat. Operators often compensate by increasing temperature or speed, triggering:

Local overheating Mechanical energy converts into excessive shear heat, leading to non-uniform increase in melt temperature.

Uneven plasticization Due to insufficient shearing, some materials form "raw material," and these insufficiently plasticized areas have poor thermal stability and are more prone to degradation.

2. Over-lubrication Increased exudation at the die lip can lead to carbon buildup, which can become the starting point for continuous scorching.

III. Formula Synergistic Imbalance: Competition and Reaction with Other Additives

Competing for adsorption with lubricants. Excessive stabilizer occupies the surface of PVC particles, affecting the normal function of internal and external lubricants and leading to lubrication system failure.

Reaction with fillers/pigments May react with certain fillers (such as calcium carbonate) or pigments, forming dark-colored compounds and exacerbating discoloration.

Additive blooming/exudation Excessive addition can lead to the precipitation of stabilizers or other small molecule additives, forming surface defects or nucleation points.

IV. "Threshold Reversal" Phenomenon for Stabilization Effects

PVC stabilization systems exhibit saturation effects.

· Within the optimal dosage range Within a proportion that is usually 1–2 phr of the total amount (unless otherwise specified), the stabilizer can effectively capture HCl and replace unstable chlorine atoms.

· Exceeding the critical value ..., free stabilizer molecules or their decomposition products can instead become media that promote cross-linking or degradation, leading to:

Gel particle formation Promoting PVC crosslinking leads to the formation of gel points that are difficult to plasticize, and these gels are prone to burning during processing.

Coking start point Gel particles or precipitates become the initiating nuclei for localized overheating and degradation.

V. Core Conclusions and Recommendations

PVC processing is a delicate process involving a dynamic equilibrium of multiple factors. Excessive stabilizer not only fails to improve thermal stability but also triggers accelerated chemical degradation and physical processing instability, leading to issues such as scorching, color deepening, and decreased mechanical properties in the final product.

Practical Advice:

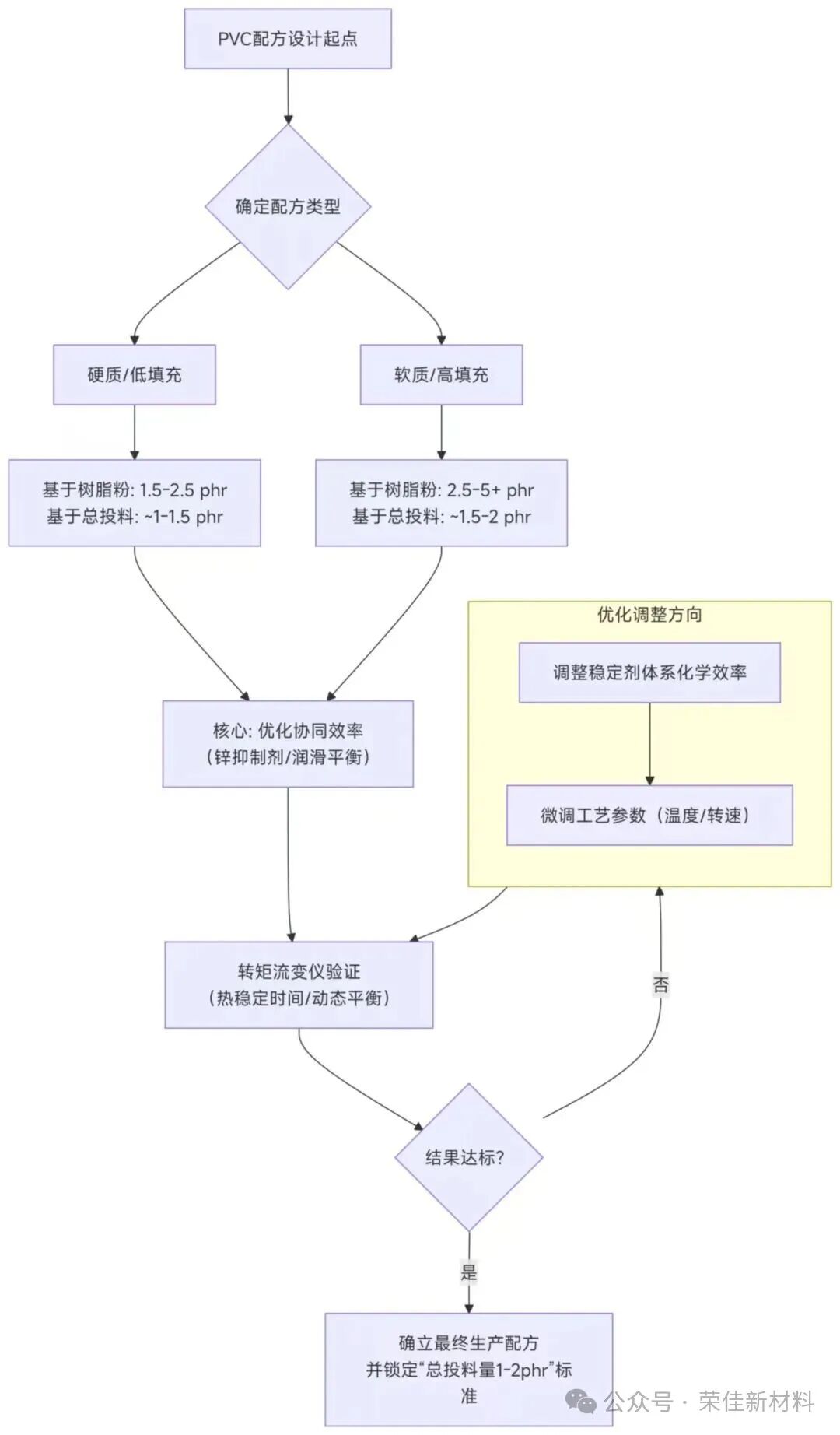

Dosage optimization. Determine the optimal addition level through torque rheometer testing (observing equilibrium torque and heat stability time). Generally, the recommended starting range for composite calcium-zinc stabilizers is 1.0–2.0 phr (parts per hundred resin) (excluding special requirements, such as high V2V2 materials), and adjustments should be made dynamically based on the resin type, processing equipment, and processing temperature.

2. Synergistic Collaboration: Ensure good compatibility of the stabilizer with other additives such as internal and external lubricants, antioxidants, etc., and evaluate the overall compatibility through small-scale trials.

Process Monitoring Avoid blindly increasing temperature or speed due to over-lubrication; uniform plasticization should be achieved by adjusting the formulation and process parameters.

Select high-yielding varieties. Choose surface-treated, highly dispersible, and synergistic high-performance composite calcium-zinc stabilizers that can achieve stabilization effects at lower dosages.

Through scientific formulation and process control, the environmental advantages of calcium-zinc stabilizers can be fully realized while avoiding the risk of scorching caused by "over-stabilization."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories