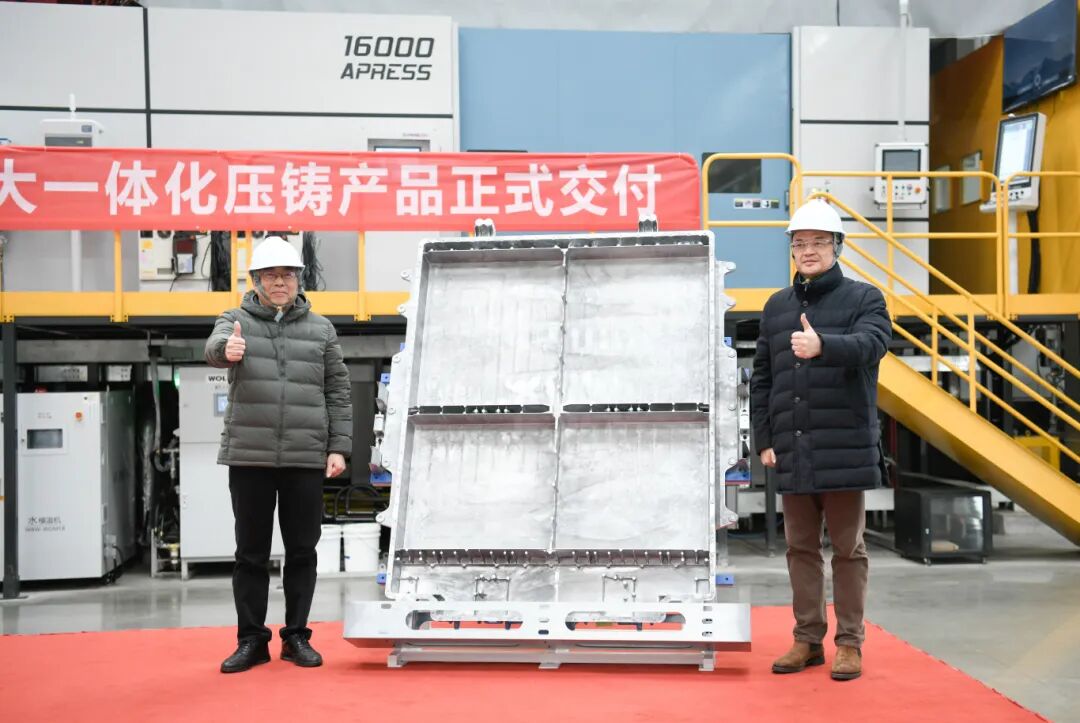

Fighting for a Good Start | Dongfeng Motor's Largest Integrated Die-Casting Production Line Delivers Its First Product Globally!

On January 21, the first product—a battery casing—manufactured by Dongfeng Motor’s 16,000T integrated die-casting production line, the largest of its kind in the world, was successfully rolled off and delivered. The delivery of this product marks a key breakthrough for Dongfeng Motor in the lightweight and integrated manufacturing of core components for new energy vehicles, injecting strong momentum into the automotive industry's cultivation of new quality productive forces for future development.

You Zheng, Member of the Standing Committee of the Party Committee and Deputy General Manager of Dongfeng Motor Corporation, attended the ceremony. Xia Xiaochuan, Secretary of the Party Committee and Chairman of Yuechuang Technology,Gao Shouwu, Deputy General Manager of Yuechuang Technology and General Manager of Dongfeng Technology; Zhan Xin, Vice President and Chairman of the Labor Union of Dongfeng Motor R&D Institute, Ye Xiaoming, Assistant to the President of Dongfeng Motor R&D Institute.and Dongfeng Motor R&D Institute, Dongfeng Technology,Yipai TechnologyRelevant domain leaders and representatives from the integrated die-casting project team attended the ceremony.

At the scene, You Zheng and Xia Xiaochuan jointly unveiled the integrated die-casting battery enclosure. Representatives from Dongfeng Motor R&D Institute, eπ Technology, and Dongfeng Motor Parts & Components signed the product acceptance agreement, marking the official entry of this product into mass production application.

This battery case is the first mass-produced product from Dongfeng Motor's integrated die-casting production line. It was developed by Dongfeng Motor's R&D Institute and Yuechuang Technology through a "complete vehicle and component synergy" innovation mechanism, and completed after 14 months of intensive effort. Compared to traditional production methods, the integrated die-cast battery case significantly enhances the safety of the vehicle's power battery system through highly integrated design. It also achieves vehicle weight reduction, energy consumption reduction, and effectively extends the range of new energy vehicles. With the production of this product, Dongfeng Motor will become the first complete vehicle manufacturer in the industry to achieve an integrated die-casting layout covering the front, middle, and rear of the entire vehicle body.

As a crucial measure in the nation's "15th Five-Year Plan" to promote new industrialization and develop new quality productive forces, high-end equipment and green manufacturing have been placed in a strategic priority position. Integrated die-casting technology, as a key path to lightweighting and integration of new energy vehicles, relies on the deep integration and synergistic innovation of materials, processes, and structural design, effectively enhancing production efficiency and low-carbon levels. Dongfeng Motor, as the first domestic vehicle manufacturer to introduce the world's largest 16,000T integrated die-casting technology, has explored innovative paths in the integrated R&D of complete vehicles and components, as well as in-depth coordination of the industrial chain. In the future, Dongfeng Motor will continue to promote the capacity construction of integrated die-casting battery boxes, body and other key components for multiple models, tackle key technologies for large-scale ultra-thin-walled battery pack shells, and deploy die-casting applications of cutting-edge materials such as magnesium alloys, further improving the lightweighting level of the entire vehicle and seizing the technological high ground in the "second half" of intelligent competition.

You Zheng stated that, looking ahead to the "15th Five-Year Plan" period, the automotive industry is undergoing profound transformations in intelligence, low-carbonization, and integration. Mastering disruptive technologies such as artificial intelligence and integrated die-casting independently has become a crucial path towards high-quality development. It is essential to update understanding with a global perspective, maintain awe of disruptive technologies, and continuously deepen open collaboration across the industrial chain. He hopes that the integrated die-casting R&D team will bravely break through and innovate, inherit the "Third Front Spirit" and Dongfeng's "Lantern Spirit," continuously tackle cutting-edge fields such as materials and processes, truly create value for users through technology, help Dongfeng win the "15th Five-Year Plan," and steadily move towards the forefront of global automotive industry development.

▲ Xia Xiaochuan and Zhan Xin unveiled the "Integrated Die-Casting Joint Innovation Studio"

To continuously promote technological innovation and industrial integration, Dongfeng Motor R&D Institute and Dongfeng Technology have jointly established the "Integrated Die Casting Joint Innovation Studio." This studio will leverage the technical strength of the R&D Institute's doctoral team and Dongfeng Technology's production resources, integrating their respective advantages in casting process manufacturing and structural design research and development. It aims to create an innovative platform that integrates technology research and development,========(achievement transformation), and talent cultivation, providing support for Dongfeng Motor to continuously achieve technological breakthroughs and industrial leadership in the field of new energy vehicles.

▲ Ye Xiaoming and Gao Shouwu issued the task battle chart for the "Integrated Die-casting Joint Innovation Studio".

▲ Dongfeng Motor R&D Institute, eπ Technology, and Dongfeng Technology representatives jointly signed the acceptance agreement for the integrated die-casting battery case product.

▲ Dongfeng Motor R&D Institute's relevant field leader introduces the progress of the integrated die-casting project

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories