Finally, someone explains the "whitening" of film during stretching!

Have you ever encountered such a situation?

When stretching the film, even though the formula and temperature haven't changed, the result turns white as soon as it's stretched.

Stretch whitening is not a minor issue; it directly reflects changes in molecular chain arrangement, crystallization behavior, and interface status. It directly determines the strength, transparency, and even subsequent performance of the film.

Today, let's systematically talk about it.

Why does your film turn white when stretched? What is the essence? How can it be improved?

First, clarify: What does "fabai" mean?

Let's not rush to discuss solutions; let's first clarify its essence. The so-called "whitening" doesn't mean the film actually turns white, but rather—Light is "disrupted."。

When the film is stretched, the interior appears.Microcracks, voids, or phase separationWhen light passes through these uneven areas, scattering occurs. Once the light is scattered, what the eyes see is not transparency, but a kind of "foggy white."

This is somewhat like freezing a glass of water into ice—water is transparent, but the interfaces and different refractive indices between ice crystals make it appear white.

In other words, whitening is an optical signal, indicating that there is a structural problem behind it.

What exactly happens when the film is stretched?

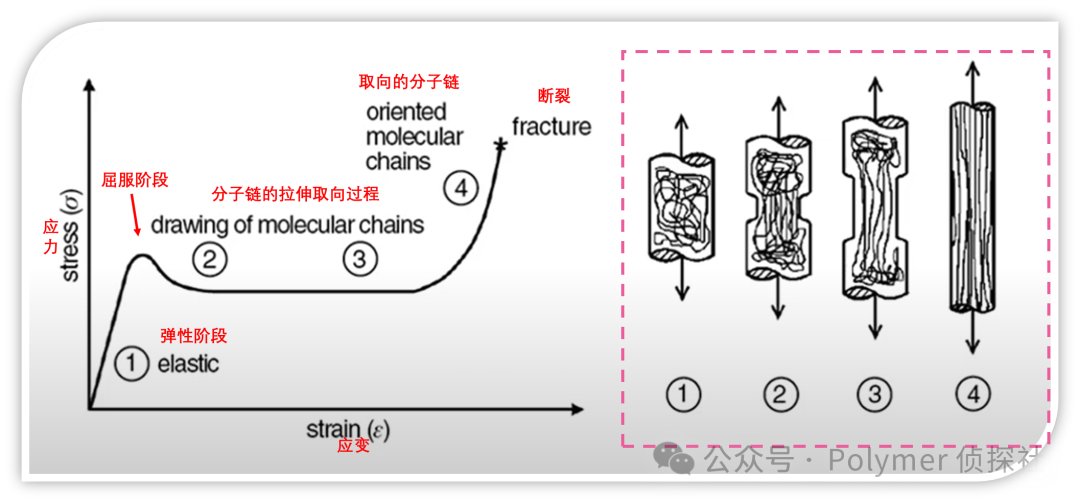

Film stretching is actually the process of "forcing" molecular chains to realign.

In a stationary state, polymer chains are like tangled "balls of yarn".

When tensile stress is applied to it, the chains begin to uncoil, straighten, and orient, forming a more orderly arrangement.

If the process is well controlled—with the right temperature and stretching speed—the molecular chains can rearrange smoothly, and the film will become...More transparent, more robust。

However, reality is often not so ideal.

If pulled too quickly, the temperature is too low, or the local stress is too concentrated, and the chain does not have time to "react," then two consequences will occur:

One way isThe molecular chain itself breaks, or microcracks that cannot be restored form between molecular chains due to slippage.;

Another way isThe amorphous region is pulled out with gaps.A micropore appears.

When these two structures appear, light begins to refract erratically, and that section of the film immediately turns "white."

In essence, stretching whitening isThe orientation behavior of the molecular chain is imbalanced.。

Why is some whitening "reversible" and some irreversible?

This point is very crucial and can help you determine what type of problem it is.

If you find that the film turns white right after being stretched, but returns to being transparent after being left for a while or slightly heated, that belongs toReversible whitening。

This situation is very common in semi-crystalline plastics (such as PP, PE), and its essence is often "silver streaking."

Under tensile stress, the material undergoes local yielding, forming a large number of micron/nano-scale microfibers and voids. These voids have a different refractive index from the polymer matrix, leading to light scattering and turning white. Reference (1)

When the stress is removed or heated, the rebound force of the molecular chains causes these microvoids to collapse or shrink, thereby restoring transparency.

For amorphous polymers, reversible whitening may more often originate from stress-induced uneven birefringence or reversible shear bands, with the recovery process being closer to the relaxation of the chain segments.References (2)

But if turning white isIrreversible——也就是不论你放多久、加热也不恢复,那就说明内部已经发生了Micro-cracking, crystal locking, or interfacial debonding。

In this situation, light can no longer pass through.

Sure, please provide the content you would like translated into English.

Reversible whitening = The chain segment is still there;

Irreversible whitening = chain segments are broken, or the structure is locked.

The first step in analyzing the cause of whitening is often to determine whether it is reversible or irreversible.

The real reason for turning white: not one, but three types of "asynchrony"

From engineering experience, the root causes of film whitening can be summarized into three categories, which I call the "three asynchronies":

① Orientation mismatch

Some regions of the molecular chain have already been stretched, while others remain unchanged, which can easily lead to localized stress concentration areas.

In this case, the whitening usually distributes along the stretching direction and the shape is relatively regular.

② Crystallization asynchrony

For semi-crystalline materials like PP and PA, during stretching, the crystallization rate is too fast, and crystalline grains suddenly grow, resulting in differences in refractive index and causing light to be scattered.

This type of whitening often occurs in situations where the temperature is relatively low and the stress is too high.

③Interface not synchronized

In multiphase systems (such as filled, blended, or coated structures), poor interfacial adhesion and compatibility can also lead to microvoids.

This whitening is often more "coarse," not localized in bands, but rather large patches of misty white.

So, we need to first identify which type of "asynchrony" we are encountering, so that our troubleshooting process doesn't become confused.

05

How to improve "whitening"?

From a technical perspective - allowing the chain to have time and space to "react"

Appropriately increase the stretching temperature to make the molecular chains more pliable.

Reduce the stretching rate to give chain segments time to orient.

Ensure uniform temperature distribution and avoid local cold spots.

If it involves multiple stages of stretching, don't stretch too aggressively in the earlier stages to allow for a gradual transition of stress.

② Formula perspective - Making the system more "stable"

Add compatibilizers and coupling agents to improve interface adhesion.

Adjust the crystallization rate appropriately, for example by adding nucleating agents or adjusting the molecular weight distribution.

For the filler system, attention should be paid to particle size and dispersion state; the larger the particles, the more likely they are to become stress sources.

3. Environmental Perspective - Don't Ignore Humidity and Dryness

Particularly for materials like PA and PET, absorbing moisture can alter the hydrogen bonding system, making them prone to localized whitening when stretched.

Many people think "a little moisture doesn't matter," but even 0.1% can affect the movement of chain segments.

④ Verification Methods—Don’t Just Look at the Appearance

It is recommended to use polarized light microscopy, DSC, or stress optical methods to determine whether it is caused by crystallization or voids.

If the whitening occurs in a stress concentration area, a noticeable optical birefringence phenomenon can usually be observed.

And the hollow part appears white, and under polarized light, it is "dark."

When encountering different types of whitening, how to judge and what to do?

I summarized it into a table:

The whitening of the film is, ultimately, not a defect, but a signal of a change in material structure.

As long as you can follow this signal down, you will be able to find the root cause in temperature, rate, interface, and formula.

As material scientists, what we fear the most is not the problem itself, but "not knowing why."

Understanding the principle of turning pale is to train your ability to see the structure from the phenomenon.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory