Finally, Someone Explains Why Flame Retardant Keeps Shedding Powder

Recently, I saw a friend leave a message: the flame-retardant PU leather they made developed a white powder after being left naturally for four weeks.

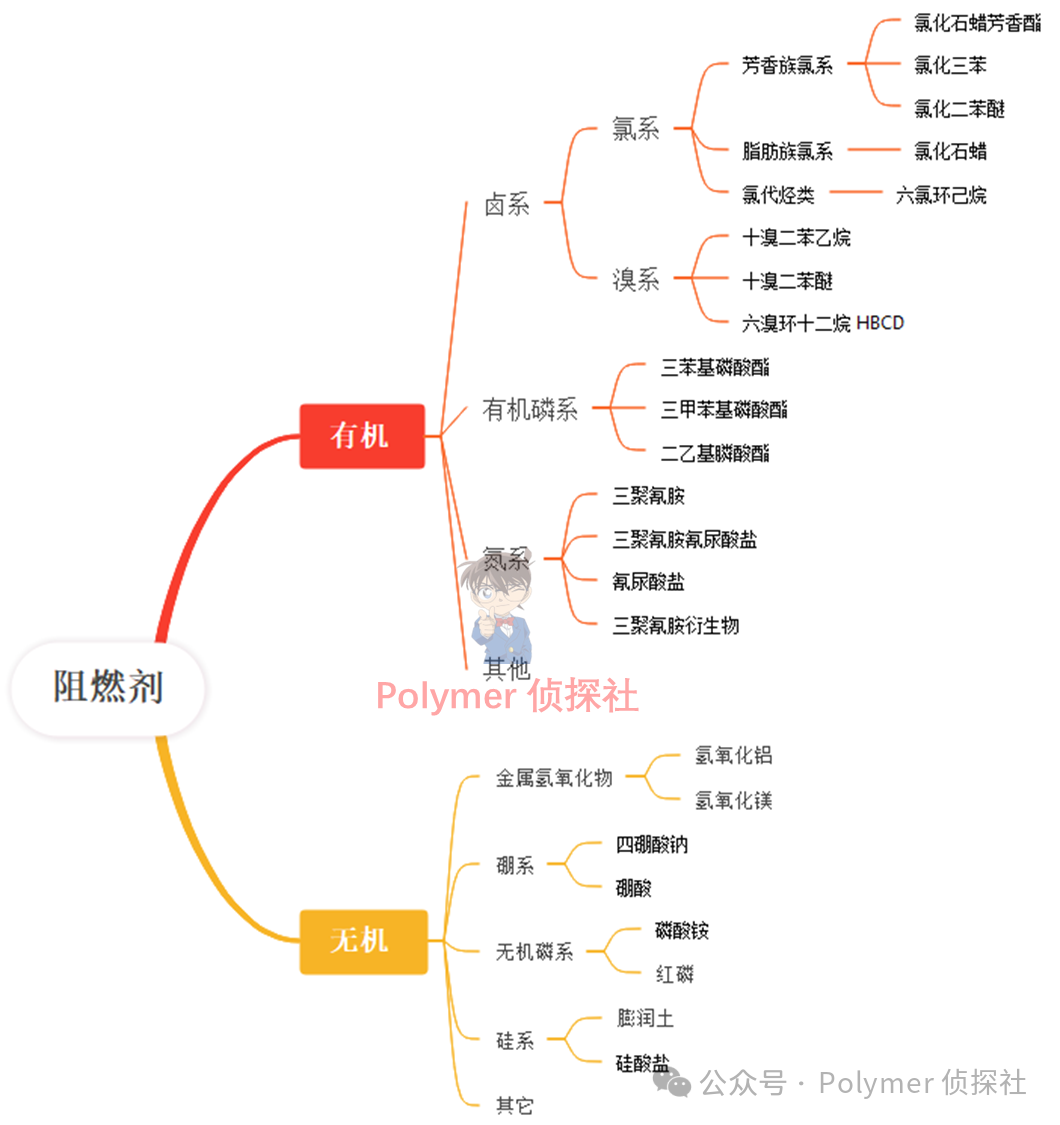

是不是很熟悉?无论你用的是氢氧化铝、氢氧化镁,还是十溴二苯醚、磷酸盐类阻燃剂,If you have done flame-retardant modification, you will inevitably encounter powder shedding.

Today, we will thoroughly explain this issue.

01

What is losing followers?

Don't rush to conclusions; let's clarify the phenomenon first.

"Shedding powder" refers to the phenomenon where a flame retardant cannot stay within the material, gradually precipitating out of the matrix and eventually floating on the surface.

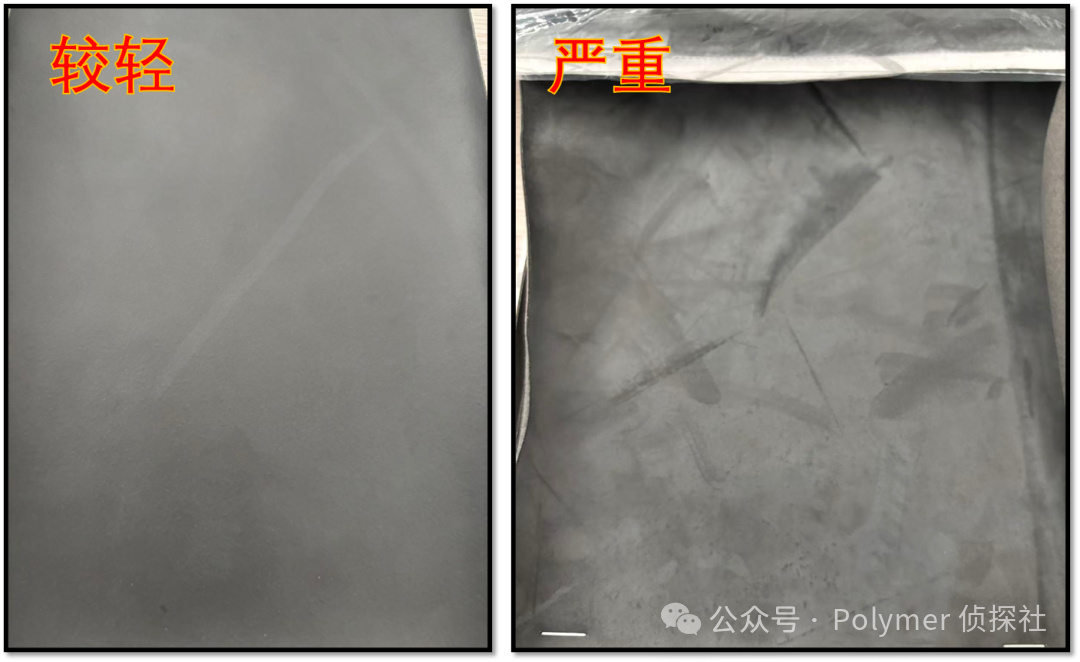

Light manifestations include surface whitening and fogging; in severe cases, there is a powdery feel to the touch, and in extreme situations, shaking the material can cause a layer of white flakes to fall off.

The essence behind this is.The compatibility between the flame retardant and the matrix is poor.The external environment (temperature, humidity, stress) combined with the above factors leads to migration and precipitation.

02

Why do flame retardants easily form powder?

The initial intention of adding flame retardants is to make materials safer in flames, but the problem is that the "character" of flame retardants often differs significantly from that of the base polymer.

Most polymer materials are organic macromolecules (non-polar or weakly polar), while many flame retardants, such as those containing phosphorus, nitrogen, halogens, or inorganic fillers, are relatively polar and have smaller molecular sizes. As a result, they cannot form a good "molecular friendship" with the matrix.

This involves a very important concept:Compatibility。

Additives with good compatibility will integrate into the system without easily separating. Additives with poor compatibility are like oil and water; they may appear mixed at first, but over time they will separate.

Flame retardants happen to belong to the category of "naturally incompatible": they have low molecular weight → easily migrate.

Large polarity differences → Thermodynamic driving force pushes them towards the surface.

Some are even crystalline powders → They are more inclined to precipitate on their own.

This is why the issue of losing followers is particularly common with flame retardants.

03

Why do some flame retardants come off easily, and why does this happen only after a period of time?

This is the most frequently asked question: Why was it fine when I first made it, but after a month it started having problems?

Actually, it's very simple: losing followers is aDynamics processIt is not completed in an instant.

When it is freshly made, the flame retardant is evenly dispersed in the matrix, just like sugar when it is just stirred in. However, over time:

The molecules begin to migrate within the system.

Once the surface reaches saturation, nucleation and crystallization gradually occur.

As the crystalline particles increase, visible white powder eventually appears.

As for why some flame retardants are particularly prone to falling off, the reasons usually fall into the following categories:

The molecular structure is too small.Fast migration speed;

The polarity difference is too large.Incompatible, strong driving force.

Excessive addition.Exceeds the "solubility limit" of the system.

The system has a large free volume.For materials like PU and PVC, the gaps between the segments are relatively large, making it easier for small molecules to penetrate through.

So, you will see that losing followers often does not happen immediately, but gradually becomes apparent over time.

04

So how to avoid losing followers? Many friends ask me:

"Blogger, can you tell me how much of this flame retardant should be added so that it won't precipitate?"

To be honest, no one dares to answer you. The additive manufacturers won't respond directly either. This is a systemic issue that cannot be resolved by relying solely on a single number.

Large companies have stable formulas not because they have "secret recipes," but because they haveSystem methodology。

They will do this:

Based on the molecular structure of the materials, select several types of compatible flame retardants that may be suitable.

Refer to several commonly used fire-retardant systems in the industry and select a preliminary.

Through DOE (Design of Experiments), scientifically verify by not changing only one variable, but by testing combinations and interactions.

Control the order of addition, content, particle size, and dispersion method.

After completion, rigorous accelerated aging and reliability testing are required for confirmation.

So, when you ask "How much should I add to not lose followers," you're actually avoiding the fundamental logic:You must try it in conjunction with your system and not be lazy.

In formula engineering, there are also some basic directions:

Try to choose flame retardants with high molecular weight and good compatibility.

Use compatibilizers or synergists in conjunction to enhance the stability of flame retardants in the system.

Reasonably control the amount added to avoid exceeding the dissolution/dispersion limit.

Strengthen dispersion processes, such as predispersing, surface treatment, and reactive introduction.

Under conditional circumstances, prioritize reactive flame retardants (chemically bonded into the material) over physical incorporation.

05

How to improve in engineering?

The issue of losing followers is indeed stubborn, but it is not without solution. The key is to start from "interface compatibility."

Surface treatment

Treat the inorganic flame retardant with a coupling agent (silane, titanate) to "clothe the particle surface with a plastic coating." One end can bond with the hydroxyl groups on the particle surface, while the other end carries an organic chain segment compatible with the resin.

Improve the wettability of the particles and the matrix to enhance the interfacial bonding.

Choose an additive-type or reactive-type flame retardant.

For example, DOPO derivatives and polyphosphates, they have a large molecular weight and are not easy to migrate.

Although it's expensive, the problem of losing followers can be greatly improved.

Add a compatibilizer to the formulation.

Add maleic anhydride grafted polymers (PP-g-MAH, PE-g-MAH) in the polyolefin system as "bridges" to enhance the interaction between the flame retardant and the matrix.

Optimize processing technology.

Improve dispersion efficiency to make flame retardant particles finer and more uniform.

However, it is important to note that excessive refinement should be avoided, as nano-sized particles are prone to agglomeration and can lead to a significant increase in system viscosity, which is detrimental to processing and performance. Therefore, appropriate dispersion processes are needed (such as twin-screw extrusion or first producing masterbatches).

Lower the processing temperature to prevent premature decomposition of small molecule flame retardants.

However, the temperature cannot be too low either, otherwise the resin will not melt properly and will be unevenly dispersed, which can lead to local precipitation instead. Therefore, this is not about simply lowering the temperature.Control the window to ensure sufficient plasticization of the resin without causing the decomposition of the flame retardant.。

Environmental Control

Pay attention to humidity control during the curing of finished products, especially in the ATH/MDH system.

Avoid storage in high temperature and high humidity.

A sentence:Improving interface compatibility is the core idea for solving the issue of losing users.

06

Loss of fans ≠ appearance issue, but rather a structural issue.

I personally believe that the issue of losing followers has long troubled the industry because most manufacturers treat it asAppearance issues"rather than"Structural problem。

It looks a bit powdery on the surface, which seems tolerable.

The truly frightening thing is: losing followers implies the migration of flame retardants, which means the flame retardant effect is declining. In other words, the material may lose its intended protection at the most critical moment.

Therefore, losing followers is not merely due to "customers finding it dirty"; it directly threatens the stability of flame retardant performance.

07

Today we went through the logic of flame retardant powder shedding.

What is ""? — Essentially, it is the precipitation of additives, not the decomposition of the matrix.

Why do flame retardants flake off? - Poor compatibility and migration of small molecules.

Some are particularly easy due to low molecular weight, large polarity differences, excess, and large free volume.

Why does it happen after a period of time? — This is a slow kinetic process.

Avoid it by relying on system matching, DOE validation, and reasonable processes, rather than asking "how much to add."

The biggest misunderstanding? Treating follower loss as an appearance issue; in fact, it reflects the stability of material structure.

So, the issue of flame retardant powdering is not about the quality of one's material over another's, but rather a matter of...Systemic CognitionThe problem of factories that can handle powder loss well often indicates that they have a deeper understanding of formulations, processes, and compatibility principles.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?