Fire at bangladesh garment factory and chemical warehouse leaves at least 16 dead

A fire broke out at a garment factory in Dhaka, the capital of Bangladesh, and an adjacent chemical warehouse on October 14 local time, resulting in at least 16 deaths and multiple injuries.

According to Reuters, Jasim, an official from the Bangladesh Fire Department, citing eyewitnesses, reported that on the afternoon of the 14th, a fire broke out on the third floor of a garment factory in Dhaka and then spread to a chemical warehouse storing bleach, plastic, and hydrogen peroxide. It took 12 fire units nearly three hours to bring the fire at the garment factory under control, but the fire at the warehouse is still ongoing.

Chowdhury, an official from the Bangladesh Fire Service, stated that rescuers have found 16 bodies on the second and third floors of the garment factory

The chief advisor of the Bangladeshi interim government, Yunus, expressed condolences to the victims of the fire. He instructed the authorities to investigate the cause of the fire and ensure that the affected families receive the necessary assistance.

The hazardous chemicals warehouse is a special place for storing flammable, explosive, toxic, and harmful substances, and its safety management is directly related to the safety of the surrounding environment and the lives and property of individuals. To help everyone comprehensively grasp the relevant safety regulations, this article summarizes the core safety knowledge points of hazardous chemicals warehouses. Let's highlight the key points!

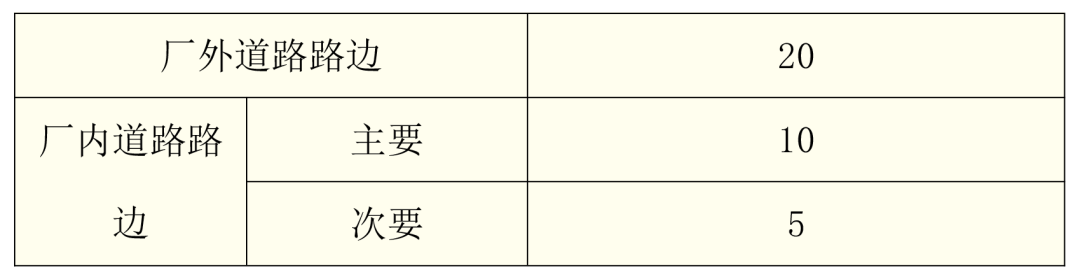

1. Distance Requirements Between Warehouses and Roads: Ensuring a Safety Buffer Zone

The distance between a Class A hazardous chemical warehouse and a road must strictly adhere to the GB50016-2014 "Code for Fire Protection Design of Buildings" standards, as specified below:

-

Distance from the roadside of off-site roads: ≥20 meters

-

The distance from the main roads in the site to the roadside: ≥10 meters

-

Distance from the roadside of secondary roads in the venue: ≥5 meters

Reasonable spacing settings can effectively reduce potential risks associated with vehicle passage (such as collisions and spark ignition), creating the first line of safety for the warehouse.

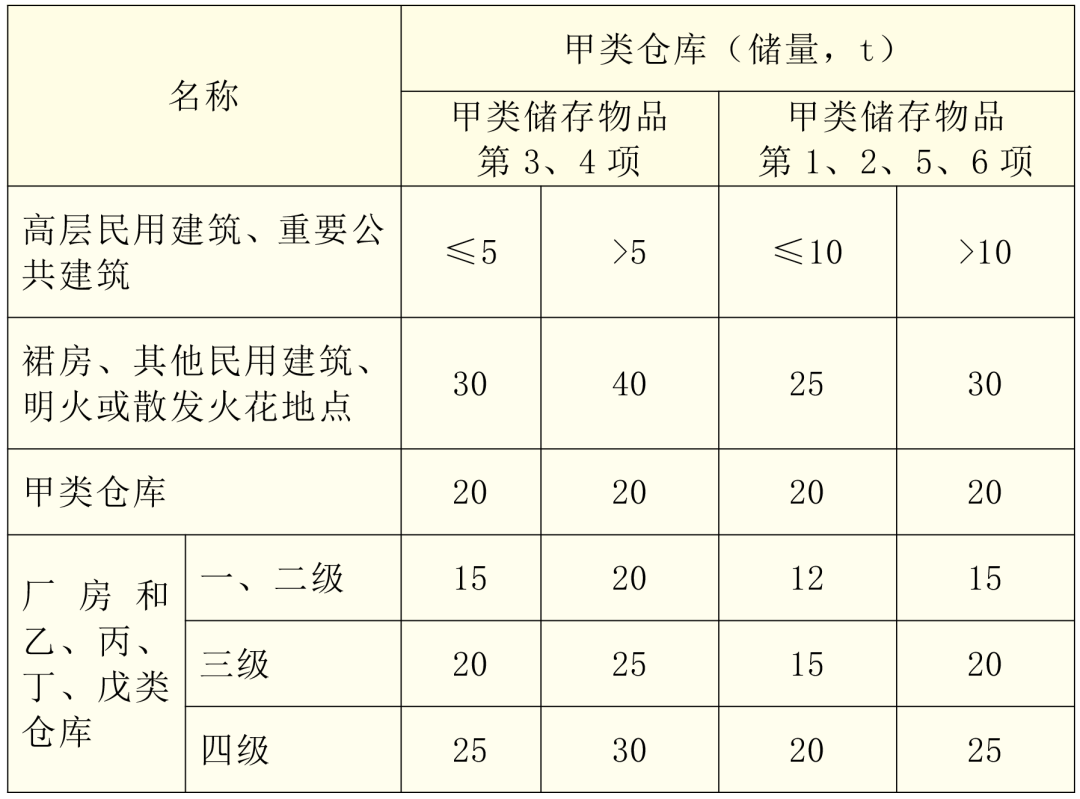

2. Fire Separation Distance Between Warehouses and Other Buildings: Strictly Prevent Cross Hazards

The fire safety distance between Category A hazardous chemical warehouses and other buildings or locations with open flames should be comprehensively determined based on the type and quantity of stored items in the warehouse, as well as the fire resistance rating of adjacent buildings (please refer to the table below for specific data).

Table 3.5.1 Fire Separation Distances (m) Between Class A Warehouses and Other Buildings, Open Flames or Spark Emission Locations, Railways, Roads, etc.

Note: The fire separation distance refers to the minimum horizontal distance between the exterior walls of adjacent buildings. It must be strictly adhered to according to regulations and should not be arbitrarily reduced.

3. Liquid Warehouse Spill Prevention: Eliminating Leakage and Dispersion Risks

According to regulatory requirements, Class A, B, and C liquid warehouses must be equipped with facilities to prevent liquid dispersion, such as:

-

Set a water barrier at the warehouse entrance with a height of no less than 15 cm.

-

The ground is constructed using impermeable concrete, with drainage channels and a collection basin installed.

In addition, for warehouses containing items that can ignite or explode upon contact with moisture (such as sodium, potassium, and other water-reactive chemicals), special waterproof measures must be taken, such as setting up rain shelters and using sealed storage containers to prevent rainwater and firefighting water from soaking the materials. According to GB50016-2014 "Code for Fire Protection Design of Buildings":

Warehouses for Category A, B, and C liquids should be equipped with facilities to prevent the dispersion of liquids.

Warehouses containing items that ignite or explode upon contact with water should implement measures to prevent water infiltration.

4. Gas Detection Alarm: Real-Time Monitoring of Leakage Hazards

Is it necessary to install a combustible gas detector in a hazardous chemical warehouse?

The answer is it must be set!

According to GB/T 50493-2019 "Design Standards for Combustible Gas and Toxic Gas Detection and Alarm in Petrochemical Industry":

-

When the concentration of flammable gas in the leaked gas may reach the alarm set value, a flammable gas detector needs to be installed.

-

When the concentration of toxic gas may reach the alarm set point, a toxic gas detector must be installed.

-

If a gas is both flammable and toxic (such as chlorine gas), priority should be given to installing toxic gas detectors.

-

In a mixture of gases, when both flammable and toxic gases may exceed the limit simultaneously, two types of detectors need to be installed separately.

V. Installation and Operation of Alarms: Standardization Ensures Safety

The installation and operation of the alarm system must meet the following requirements:

1. Two-level alarm mechanism: Both combustible gas and toxic gas detection must adopt a two-level alarm system (low concentration warning and high concentration emergency alarm), and the alarm level for toxic gases takes priority over the alarm for combustible gases of the same level.

2. Signal Transmission: Alarm signals need to be transmitted in real-time to a manned control room or central control room; secondary alarm signals for combustible gases and system fault signals must be sent to the fire control room.

3. Audible and Visual Warning: The control room operation area should be equipped with audible and visual alarm devices; alarm systems should be arranged in the field area according to the size and ventilation characteristics to ensure that surrounding personnel can be quickly alerted in case of a leak.

6. Warehouse Explosion Prevention: Controlling Sources to Eliminate Hidden Dangers

1. The electrical equipment within warehouses storing flammable and explosive hazardous chemicals, such as switches, lighting fixtures, fire detectors, and mechanical ventilation systems, must be explosion-proof. Their design and installation should comply with the requirements of the "Code for Design of Electrical Installations in Explosive Atmospheres" (GB 50058-2014). Operational tools such as electric forklifts and pallet trucks should also meet explosion-proof requirements.

According to Article 6.6.1 of the "Code for Fire Protection Design of Petrochemical Enterprises (2018 Edition)" (GB 50160-2008), warehouses for Class A, B, and C items should be well-ventilated. Warehouses that may generate explosive gas mixtures or form explosive mixtures like dust and fibers in the air should use spark-free flooring, and waterproof layers should be installed when necessary.

7. Accident Fan: Emergency Ventilation to Control Risk

The accident fan is an important emergency device in the event of a gas leak in the warehouse, and its installation must comply with the "GB50019-2015 Design Code for Heating, Ventilation, and Air Conditioning of Industrial Buildings".

Exhaust outlet location: must not be placed where people frequently stay or pass by; horizontal distance from mechanical air supply outlet should be ≥20 meters (if insufficient, it must be ≥6 meters higher than the air inlet); for exhaust containing combustible gases, it should be ≥20 meters away from the point where sparks may fall; must not face outdoor aerodynamic shadow areas or positive pressure zones.

Control switches: Electrical switches should be installed on the interior walls near the outer door to ensure they can be quickly activated in case of an emergency.

Safety management of hazardous chemical warehouses is no small matter; every regulation is derived from lessons learned through past accidents and bloodshed. Adhering to the above requirements is essential to prevent accidents at their source and to build a solid "safety barrier" for hazardous materials storage.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?