From General to Specialized: How to Choose Additives for High-Temperature Plastics

Additives suitable for general polymers do not achieve optimal performance in high-temperature polymers. This is due to the lack of high-temperature stability in these traditional additives. This situation has driven the development of specialized additives for high-temperature polymers.

The article will introduce three types of commonly used core high-temperature additives for high-temperature polymers.Antioxidants, flame retardants, and processing aids.Analyze their characteristics in various high-temperature polymers in detail.

Part.01

High-temperature polymers' demand for additives

In large-scale production fields such as aerospace, automotive, and electronics, there are higher demands for a balanced performance in thermal properties, mechanical properties, electrical properties, optical properties, and tribological properties of high-performance components.

Some specialty polymers used in these fields,The peak or long-term heat resistance temperature exceeds 250℃.To achieve optimal performance, these polymers often require the addition of specific additives, which are the materials that help the polymers exhibit excellent performance.

The choice of additives depends on the following two points:

The type of polymer added

Its application scenarios

Reasonable selection of additives helps in developing high-value-added plastics with enhanced durability and other advantages. Additives are particularly crucial for improving the performance of high-temperature polymers.

The three most commonly used additives for high-temperature polymers include:

Flame retardant

Antioxidant

Processing aid

The following will delve into the characteristics brought by each type of additive to high-temperature polymers...

Part.02

Flame retardant

The commonly used commercial flame retardants for high-temperature polymers can be categorized into the following types:

Brominated and chlorinated flame retardants

Phosphorus-based flame retardant

Metal oxide

The material is in general polymers.Most commonly usedFlame retardants, butSome brominated compounds pose health risks.These concerns have prompted the industry to develop halogen-free flame retardants suitable for high-temperature polymers.

There are two types of halogen-free flame retardants that can be effectively applied to high-temperature polymers, namely (Coke type) andMetal oxide(Endothermic type).

Phosphorus-based flame retardantsIncluding organic and inorganic compounds, specifically:

Organophosphate esters

Phosphate

- Halogen-containing phosphorus compounds

Inorganic phosphates

Metal hydroxideIt is the most commonly used halogen-free flame retardant in high-temperature polymers.Aluminium trihydroxideWith low cost and abundant natural resources, it generates alumina through an endothermic reaction, absorbing the heat from the flame. However, the drawback of metal hydroxides is that achieving the desired flame retardant effect in high-temperature polymers requires a high additive amount. A high additive amount can negatively impact the mechanical properties and processing performance of high-temperature polymers.

Other various chemicalsHigh-temperature polymers can also be endowed with flame-retardant properties, includingBoron compounds, melamine, and ammonium sulfamateThe development of novel flame retardant materials for high-temperature polymers is ongoing, including polymer-clay nanocomposites (effective at low additive levels) and silicon-based materials (which can form protective surface coatings during fires and are currently in the research stage).

Flame retardant masterbatchThe formulation is usually customized based on the molecular structure and melt viscosity of the base high-temperature polymer. The selection of flame retardants should be based on the types of flame retardants allowed, the standards that must be met, and the critical mechanical performance requirements of the product. These factors are crucial in determining the optimal flame retardant for a high-temperature polymer.

Part.03

Processing additives

Processing additivesThe incompatibility with high-temperature polymers can negatively affect the mechanical properties of the final product. As a result, the industry has been focusing on improving the compatibility between the two in recent years, particularly by introducing chemical functional groups into fluorinated polymers that can interact with the base high-temperature polymers. The type of chemical functional groups used largely depends on the type of high-temperature polymer being processed.

The mechanism of action of processing aids is as follows:

Fluoropolymer forms a coating on the inner walls of the extruder barrel and mold.

Extruder back pressure decrease

The reduction of pressure allows high-temperature polymers to be processed at lower temperatures.

Reduce degradation phenomena during the polymer processing.

The summary of high-temperature additives activities clearly indicates that as the applications of these high-temperature polymer materials continue to expand, the development of additives will need to continue meeting stringent material requirements. Only through such efforts can the performance of high-temperature polymers be effectively optimized for specific ideal applications.

Part.04

Antioxidant

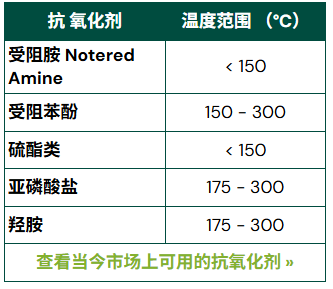

The hindered amine antioxidants shown in the table are suitable for processing at lower temperatures and cannot be used for high-temperature polymers; whereas phosphite esters and hydroxylamine antioxidants are specifically developed for high-temperature polymers.

One of the commonly used phosphite antioxidants for high-temperature polymers is alkyl-aromatic phosphite. It acts by decomposing the hydroperoxide intermediates during the oxidation process, being effective for most high-temperature polymers, reducing changes in melt viscosity and minimizing discoloration.

Challenges faced by antioxidants

During storage or processing, phosphite esters can undergo undesirable hydrolysis reactions when exposed to moisture or water. This reduces the activity of the stabilizers and implies lower suitability in highly hygroscopic polymers such as polyamides. To address this issue, the industry combines alkanolamine components with phosphite esters, and such formulations perform better than single phosphite ester stabilizers.

The processing methods of different high-temperature polymers vary, which also poses challenges for antioxidants. Each processing method has its unique time-temperature curve; for instance, the manufacturing processes in the aerospace field differ from those in the electronics field. Therefore, antioxidant stabilizers must provide stable protection for polymers in these processing scenarios.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory