Golden Hair Technology Wins Two Invention Patents, Solving The Problems Of Edge Sealing Strength And Casting Precipitation In Biodegradable Films

Jinfang Technology Co., Ltd., Zhuhai Jinfang Biomaterials Co., Ltd., and Liaoning Jinfang Biomaterials Co., Ltd. have obtained two patent authorizations: "A biodegradable material and its preparation method and application," patent publication number CN119823537B, application date December 2024; "A biodegradable composition with low flow exudation and its preparation method and application," patent publication number CN119823547B, application date December 2024.

A biodegradable material, its preparation method, and application.

The present invention relates to a biodegradable material and its preparation method and application. By combining biodegradable polyester with a certain number average molecular weight and polylactic acid with a certain number average molecular weight and D-lactic acid unit content, the initial edge sealing strength and long-term edge sealing strength of the biodegradable material when made into a film are significantly improved.

Background Technology

Compared to traditional PE, biodegradable materials have weaker edge sealing strength, especially in terms of long-term edge sealing: after being placed for a week or longer, the edge sealing strength of biodegradable films rapidly declines. This limits their application in areas such as logistics courier bags, garment bags, catering bags, and food bags. Currently, there is a strong market demand for good initial edge sealing and long-term edge sealing: on one hand, with the development of the industry, lightweight thinning is a major trend in the future production of biodegradable films. Under this trend of thinning, the edge sealing strength of biodegradable films faces greater challenges; on the other hand, most of the current market films are first made into films and then processed into products through slitting and sealing, with a turnover time of 10 days. Additionally, some products are processed into films domestically and then transported overseas for final processing into products, with a maximum turnover time of 3 months.

The primary objective of this invention is to overcome the poor sealing strength of biodegradable films in current technology, especially the issue of long-lasting sealing strength, by providing a biodegradable material.

The biodegradable material comprises the following weight parts of components: 85-92 parts of biodegradable polyester, 3-8 parts of polylactic acid, and 0-8 parts of inorganic filler. The biodegradable polyester is a copolymer of dicarboxylic acid and/or its ester derivatives and diol, and the number-average molecular weight of the biodegradable polyester is 50,000 to 100,000; the number-average molecular weight of the polylactic acid is 60,000 to 160,000, and the content of D-lactic acid units in the polylactic acid is 8-51 mol%.

Studies have found that by controlling the number average molecular weight of biodegradable polyester within a certain range, the resulting biodegradable material can be used to prepare films for edge sealing. Under instantaneous high temperatures, the biodegradable polyester molecules can quickly diffuse and entangle, thereby improving edge seal strength and long-term edge seal strength. If the number average molecular weight of biodegradable polyester is too small, although the molecules can still quickly diffuse and entangle during edge sealing, the bulk strength of the material decreases significantly, which leads to the inability to improve edge seal strength. Conversely, if the number average molecular weight of biodegradable polyester is too large, the molecules find it difficult to quickly diffuse and entangle, making it hard to improve edge seal strength. In addition, the number average molecular weight of polylactic acid and the content of D-lactic acid units also need to be controlled within a certain range to enhance compatibility between polylactic acid and biodegradable polyester, thereby ensuring the edge seal strength and long-term edge seal strength of biodegradable materials.

The initial edge seal strength grade of the biodegradable material of the present invention is above 4.3, and the long-lasting edge seal strength grade is above 3.0, which not only has good initial edge seal strength but also has good long-lasting edge seal strength.

A biodegradable composition with low streaming precipitation, its preparation method, and application.

The invention relates to a low-stripe-exudation biodegradable composition and its preparation method and application. By adding an anti-exudation agent and phosphite antioxidants to a biodegradable composition primarily made of polylactic acid, the issue of stripe exudation in the biodegradable composition is effectively improved.

Background technology

Biodegradable materials are mainly used for film preparation, typically through the casting process to make biodegradable materials into films. The casting process is an efficient production method that produces unstretched, unoriented flat extruded films by rapidly cooling the melt. This process is characterized by high production speed and output, and it achieves excellent film transparency, glossiness, and thickness uniformity, making it suitable for large-scale production of biodegradable material films.

Among them, biodegradable materials based on polylactic acid (PLA) have a problem: due to the characteristics of PLA itself, during the casting process at high temperatures (200-220°C) and certain pressures (extrusion pressure 3-5 MPa), PLA tends to precipitate oligomers that accumulate on the casting rollers. The accumulation of these precipitates on the rollers not only affects the quality of subsequent products but also requires regular cleaning of the casting rollers, increasing production costs.

The precipitation of polylactic acid in the casting process is difficult to completely avoid, but reducing the precipitation of degradation products during the casting process can greatly enhance the processing stability of the material and the quality of the product, improve terminal production efficiency, reduce production losses, and bring significant economic benefits.

The primary objective of this invention is to overcome the severe issue of precipitate formation in the casting process of biodegradable materials with polylactic acid as the main resin in current technology, and to provide a biodegradable composition with low precipitate formation during casting.

The low migration biodegradable composition includes the following components in parts by weight: 69-91 parts polylactic acid, 0-16 parts flexible biodegradable polyester, 0-11 parts filler, 0.1-3.1 parts anti-migration agent, and 0.1-3.1 parts phosphite antioxidant.

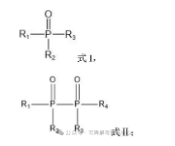

The anti-precipitation agent is a phosphorus compound with a structure shown in formula I or formula II.

Studies have found that during the casting process, under high temperatures (200-220°C) and certain pressure conditions (3-5 MPa), polylactic acid easily generates free radicals, which can lead to the degradation of polylactic acid into oligomers, resulting in precipitation. The invention incorporates phosphite antioxidants, which can react to some extent with the free radicals generated by polylactic acid during the casting process, thereby reducing its decomposition rate and improving the precipitation issue during the casting process of biodegradable compositions to a certain extent. However, the improvement in the precipitation issue of biodegradable compositions by adding only phosphite antioxidants is limited.

Further research has found that the issue of film casting precipitation in biodegradable compositions can be significantly improved by adding specific anti-precipitation agents. The reason is that polylactic acid or other biodegradable polyesters in biodegradable compositions contain trace amounts of tin and/or titanium elements, which not only catalyze the synthesis of polylactic acid or other polyesters but also have a certain catalytic degradation effect on polylactic acid under the high temperature and high pressure of the film casting process. The addition of specific anti-precipitation agents can chelate the metal ions of these metal catalysts, preventing the catalytic degradation of polylactic acid by metal catalysts. The anti-precipitation agents work synergistically with phosphite antioxidants, thereby significantly improving the issue of film casting precipitation in biodegradable compositions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage