Haitian International Shines at 2025 Jakarta Plastics & Rubber Exhibition: Full-Chain Services for Indonesian Customers from Production to Maintenance

On November 19, 2025, Indonesia's largest plastic industry event, the Indonesia International Plastic & Rubber Exhibition, will grandly open at the Jakarta International Expo, and Haitian International will...Booth No. C3-7618。

With the deepening advancement of Indonesia's local manufacturing protection policies, the injection molding machine industry is experiencing a dual opportunity period of development and competition. The exhibition site brought together many peers in the plastic machinery industry who are entering the Indonesian market for the first time.

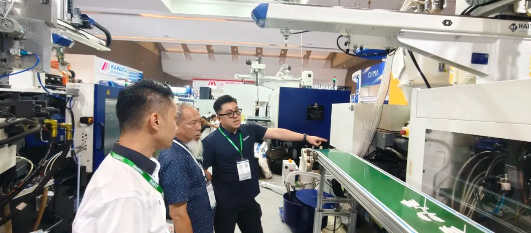

As the core exhibitor of this exhibition, Haitian International made a grand appearance at the prime location at the main entrance of Hall C3, with the largest booth area of 8×21 meters, becoming the focal point of the exhibition. Haitian International showcased three models featuring technological innovations and collaborated with Haitian Precision to display a CNC machining center, collectively demonstrating Haitian Machinery's solid capabilities in the equipment processing field.

Haitian's comprehensive cycle plan supports the growth of manufacturing in Indonesia.

Haitian MA3800H/1280PRO Injection Molding Machine

Trade show site,Haitian MA3800H/1280PRO Injection Molding MachineDemonstration of producing a 500ml milk tea cup with a 1 out of 6 ratio.The raw material uses custom-made MFI=60 milk tea cup-specific PP material from Haitian Tongchuang, paired with the Haitian Zhilian high-speed high-strength robotic arm VS1100-ID.

Haitian MA1600M/570-E400 Injection Molding Machine

Haitian MA1600M/570-E400 injection molding machine focuses on the manufacturing of 1 out of 1 dual-color PC water cups.With the integration of Lingyi's patented blow molding machine system and the independently developed second-generation color powder machine, combined with Haitian Zhilian's three-in-one solution and self-developed servo manipulator, a stable and efficient production cycle is ensured. This enables more application possibilities for single-color molds and supports more diverse color variations in ordinary consumer goods molds.

Niigata Machinery MD100S8000 All-Electric Injection Molding Machine

Niigata Machine's MD100S8000 all-electric injection molding machine demonstrated on-site production of 1 out of 4 cavity electrical folding connectors.Using pure color PA66 nylon material and paired with Haitai Zhilian five-axis servo robotic arms, the core advantages are concentrated in high precision, high stability, and high adaptability.

The model adopts high-precision structural design to ensure dimensional stability of thin-walled/precision parts, and dynamic pressure holding and precise control of clamping force ensure consistency in the molding of thick-walled parts. Dual screw injection and temperature control technology reduce material plastification fluctuations, lowering defect rates. Ultra-low-speed injection and anti-flow extension functions tackle the process challenges of thick-walled transparent parts, improving the yield rate. Independent motor linkage achieves efficient production while accommodating flexibility needs, providing full support for customers from trial production to mass production, and facilitating the rapid deployment of high-quality products.

In addition, the CNC machining center V8 showcased by Haitian Precision, a subsidiary of Haitian Machinery, has become a best-selling model in Southeast Asia, fully meeting customers' mold repair and processing needs. As the only machining center in the entire exhibition hall, it attracted many customers to stop and visit. This fully demonstrates Haitian Machinery's capability to provide comprehensive solution support for customers, "from production to factory maintenance."

Empowerment never stops!

Haitian International and Indonesian Plastics embark on a new journey together.

Looking ahead to 2026, Haitian International will continue to deepen its presence in the Indonesian market, offering advanced solutions that are more aligned with local needs. With high-quality products and services as our foundation, we are committed not only to fully meeting the current production needs of our customers but also to accelerating the upgrade and development of the Indonesian plastic injection molding industry, effectively supporting the growth and expansion of local manufacturing enterprises.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory