Hemp-Based Biocomposites Arrive! Research Shows Performance Superior to Traditional Plastics, Bio-Based Materials Continuously Penetrate Automotive Components

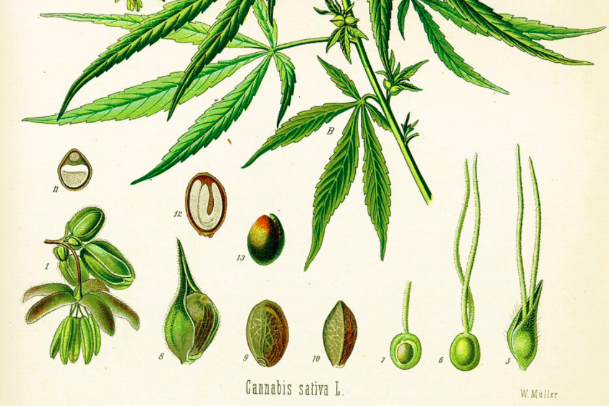

On December 29, Observed by Zhuansu Shijie, researchers at Western University in London, Ontario, Canada, conducted innovative research by grinding hemp stalks into powder, attempting to replace the commonly used high-density polyethylene pellets in traditional plastics. This hemp powder can be integrated into existing packaging production processes without special technology or additional steps. Although its strength and ductility do not meet traditional plastic standards, it is superior to other plant-based materials and has applicability in packaging and other fields.

Hemp biocomposites are composed of hemp fibers combined with matrix materials. During preparation, hemp fibers are first separated, and the hemp stalks are processed into micro-powder before being mixed with the matrix materials, which are often sourced from renewable resources. However, not all polymers used in hemp biocomposites come from plants; petroleum remains a primary source, which makes many hemp plastic products that claim to be sustainable actually mixtures.To manufacture bioplastics entirely from hemp, such as those using polylactic acid (PLA), it is necessary to break down and recombine hemp cellulose. Only then will the material be 100% biodegradable with high tensile strength.。

Hemp-based materials have what "magic" that makes them superior to plastic!

The advantages of using hemp biocomposites are numerous. In terms of soil improvement, hemp stalks have a growth cycle of only about 4 months, much shorter than that of trees, and require fewer pesticides or herbicides. It replenishes soil nutrients and can remove pollutants, serving as a rotation crop that aids in soil restoration. At the same time, hemp plants absorb a large amount of carbon dioxide during growth, making it a carbon-neutral material.

Many hemp biocomposites are biodegradable, capable of natural decomposition, reducing environmental harm. They can be molded into various shapes, are lightweight, and have a wide range of applications, covering automotive parts, construction materials, packaging, and consumer goods, combining the advantages of hemp fibers and bio-based polymers or resins.

Image source: LAMPOON

Historically, there have been attempts to use hemp materials in automobiles, with Henry Ford being a pioneer in exploring the potential of hemp-based materials. In 1937, he created a prototype car body using hemp-based plastic materials, combined with resin adhesives for the outer panels. Ford also incorporated various soy-based plastic components, and the car body could be made with plant oils, hemp-derived oils, or biofuels. To demonstrate the elasticity and strength of the body, Ford personally struck the rear end with a wooden mallet, and the body did not bend or break. However, due to the emergence of synthetic materials like nylon and restrictions on hemp production in the United States, hemp-based materials were not widely adopted in automotive manufacturing, leading to the project's termination and the lack of mass production of hemp cars.

Combining with plastics may become a breakthrough for the application of bio-based materials.

The development direction of hemp-derived materials lies in the development of hemp-based polymers. Biocomposite materials are limited in their application in packaging due to their rigidity, while hemp-based polymers are directly derived from the cellulose of hemp plants. Although they have been successfully developed in laboratories, they have not been commercialized. The main obstacles are the late start of the hemp industry, which requires time, funding, and support from various parties, as well as challenges related to the end of the lifecycle and compatibility with waste management infrastructure.The research from Western University invigorates related studies and points out that the production cost of biomaterials is currently higher than that of traditional plastics.。

Hemp biomass is the residual material after the cultivation and harvesting of industrial hemp. An international team of scientists is researching how to enhance its value and exploring its potential applications in next-generation food packaging. They employ green extraction and processing methods, such as low-eutectic solvent extraction, to harness the bioactivity of hemp fibers for use in packaging manufacturing. The study aims to investigate whether integrated approaches can improve the performance of hemp-based food packaging, and the results indicate that the combination of hemp characteristics with green technologies can help expand its conversion scale. However, industrial and technical barriers, such as the heterogeneity of hemp raw materials, hinder widespread application, necessitating the adoption of AI-driven optimization methods and standardized regulatory frameworks.

Biobased materials have continuously made breakthroughs in automotive components.

In the automotive interior sector, the application of bio-based materials is increasing. Several car manufacturers such as Bentley, Ferrari, Ford, Tesla, BMW, and Volkswagen have adopted bio-based materials. BMW's M division has redesigned seats using flax-based materials, Volkswagen has partnered with startups to develop bio-based materials, and the dashboard of the Porsche 911 is made using hybrid bio-based fiber materials. However, the widespread use of bio-based materials also brings challenges, such as Porsche experiencing mold issues when parked for long periods, indicating an urgent need to improve their moisture resistance and weather durability. It's also important for car owners to understand the characteristics of interior materials for vehicle maintenance.

According to Zhuansu Shijie, since the beginning of this year, the topic of recycled plastics has gained attention, with OEM car manufacturers in the automotive industry experiencing increased demand for them, both to save costs and to align with sustainable development trends. Japanese car manufacturers such as Honda and Nissan are increasing the proportion of recycled plastics used to meet European regulatory requirements.

The leaders in the automotive industry have demonstrated the feasibility of integrating recycled plastics into new vehicle technologies, using post-consumer recycled plastics in multiple components. Policy measures are also promoting the use of recycled plastics, as multiple departments in our country have jointly issued plans to explore increasing the requirements for recycled plastic usage. The Central Committee of the Communist Party of China and the State Council have issued opinions to improve the quality of recycled materials and products. In October, Tianjin established a central enterprise focused on waste plastic recycling, and in the future, recycled plastics are expected to be rapidly promoted in the automotive manufacturing industry.

Epilogue:

Currently, bio-based materials are mainly popularized in automotive interior parts, while recycled plastics are used more widely, covering not only interior parts but also exterior parts and some chassis system structural/functional components. At present, the application of recycled plastics and bio-based materials in automotive electric drive systems and intelligent equipment is at an initial stage, but with technological advancements and increased environmental awareness, their application prospects will become increasingly broad.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories