How Can Modified Carbon Fibers Achieve Dual Leap in Mechanical and Thermal Stability of Polyamide (PA)?

Polyamide (PA) resin hasWear-resistant, heat-resistant, and chemically resistant, as well as easy to process.Polyamide 6 (PA6) is widely used in fields such as construction, clothing, packaging, sports, and electronics, among other advantages. However, PA has certain drawbacks.Poor dimensional stability and low strength defects.Limit its application to specific fields.

Carbon fiber (CF) hasHigh strength, low density, high temperature resistanceThe advantages of utilizing CF to enhance PA6 can expand the application fields of PA6.

PA6/CF composite materials combine the advantages of both, exhibiting excellent mechanical properties, high-temperature resistance, and recyclability. They have broad application prospects in fields such as aerospace, construction, automotive, sports, electronics, and healthcare.

PA6/CF composite materialThe composite is mainly composed of CF, PA6, and an interfacial layer. The interfacial layer plays a role in connecting CF and PA6, as well as transmitting external forces. The good compatibility between CF and PA6 is a prerequisite for ensuring the excellent performance of the interfacial layer, as it can increase the contact area between CF and PA6 and enhance physical and chemical bonding, while also reducing the occurrence of defects, which directly affects the mechanical properties of PA6/CF. However, the smooth surface of CF is chemically inert, resulting in a weak ability to bond with the PA6 interface.It is easy to become a weak bonding area, making it difficult to fully utilize its mechanical performance advantages.。Therefore, improving the surface activity of CF and enhancing the interfacial performance between CF and PA6 are of great significance for improving the mechanical properties of PA6/CF.

Methods for improving the surface activity of CF includeOxidation method, chemical grafting method, and padding method.Among them:

Oxidation methodThe number of polar functional groups on the CF surface will increase, but strong oxidation will cause some damage to the CF.

Chemical grafting methodIt is possible to introduce active groups on the CF surface, but this method is complicated to operate.

The sizing agent introduces active groups on the CF surface without damaging the CF, and it can also enhance the interfacial performance of the composite materials through similar compatibility, physicochemical interactions, and induced crystallization.Sizing methodThe process is simple and is an effective method for modifying CF.

Polyurethane (PU)Its chemical structure is similar to PA6, with good thermal stability, and is an ideal modifier for the compatibility of CF and PA6.Coating agent。

KARSLI et al. studied the effects of different sizing agent modifications on CF/PA66 mechanical properties, and the results indicate:PU as a sizing agent has the greatest effect on improving the tensile modulus of composites.Zhao et al. modified carbon fiber (CF) with a water-based polyurethane sizing agent, significantly increasing the polar functional groups on the CF surface. The bending strength of CF/PA6 was improved by 28.6% compared to when CF was not added.

This experiment uses PU as a sizing agent to modify CF and prepare PA6/CF composites, studying the compatibility between CF and PA6 as well as the mechanical properties and thermal stability of CF/PA6. The aim is to develop PA6/CF composites with excellent performance.

1. Experimental Section

1.1 Main Materials

Acetone: Industrial grade, 98% mass fraction, Chengdu Xinghai Tian Chemical Co., Ltd.

CF: T700SC-6000, diameter 7μm, Toray Industries, Japan.

Water-based PU: PU-403, solid content 50%, Anhui Zhong'en Chemical Co., Ltd.

PA6: B3WG1, BASF SE, Germany.

1.2 Instruments and Equipment

Scanning Electron Microscope (SEM): S-3400N, Hitachi, Japan.

Optical Contact Angle Measuring Instrument: SDC-200S, Fuyang Feiler Technology Co., Ltd.

Universal Testing Machine: SHK-A102, Suzhou Jianzhuo Instrument Technology Co., Ltd.

Thermogravimetric Analyzer: RC3005, Wuhan Rongce Instrument Co., Ltd.

1.3 Sample Preparation

1.3.1 CF Surface Degumming

In order to reduce defects such as filament breakage due to friction and collision during production and transportation of CF, the surface of commercial CF is also sized. However, the properties of different sizing agents differ from those of the matrix, and the concentration of commercial sizing agents is difficult to achieve optimal results. Therefore, the surface of CF is subjected to desizing treatment. The CF is immersed in an acetone solution for 12 hours to remove the original sizing agent, then taken out and dried in an oven at 80°C for later use. The untreated and treated CF are referred to as NCF and DCF, respectively.

1.3.2 CF Surface Sizing Modification

Mix the PU sizing agent with deionized water to prepare a solution with a mass concentration of 0.2 g/mL. Immerse the previously treated DCF in the PU solution for 5 minutes for sizing. Dry the sized CF at 100°C for 10 minutes to remove moisture, and place it in a desiccator for later use. The sized CF is referred to as SCF.

1.3.3 Preparation of PA6/CF Composites

Table 1 shows the formulation of pure PA6 and PA6/CF composites. According to Table 1, weigh PA6 and SCF and add them into a high-speed mixer for thorough mixing. Then, use an extruder for pelletizing, setting the temperature of each zone of the extruder to 180~280°C. After extrusion, the material is cooled in a water tank and cut into 5mm pellets. Then, dry them in an 80°C oven for 6 hours. Finally, perform injection molding with an injection temperature of 280°C and a mold temperature of 90°C, and allow it to naturally cool to room temperature to produce samples of the desired size.

1.4 Performance Testing and Characterization

SEM Test: Use a scanning electron microscope to observe the microstructure, with an accelerating voltage set to 15kV.

Contact Angle Testing: Use optical contact angle measurement to test the contact angle of PA6 melt on NCF, DCF, and SCF surfaces.

Single filament tensile strength test: Test the tensile strength of NCF, DCF, and SCF single filaments according to ISO 11566:1996, with a tensile rate of 1mm/min.

Interlayer shear strength testing: Conducted according to GB/T 30969-2014, with sample dimensions of 30mm × 10mm × 4mm and a shear rate of 2mm/min.

Tensile strength test: conducted according to GB/T 1447-2005, with dumbbell-shaped specimens, sample dimensions of 180mm×25mm×4mm, and a tensile rate of 2mm/min.

Bending Strength Test: Conducted according to GB/T 1449-2005, with sample dimensions of 80mm×10mm×4mm and a bending rate of 5mm/min.

Heat Resistance Test: Conducted using a thermogravimetric analyzer. Approximately 5mg of the sample is taken, in a nitrogen environment, with a heating rate of 10℃/min.

2. Results and Discussion

2.1 Modification Analysis of CF

2.1.1 Micromorphology of CF

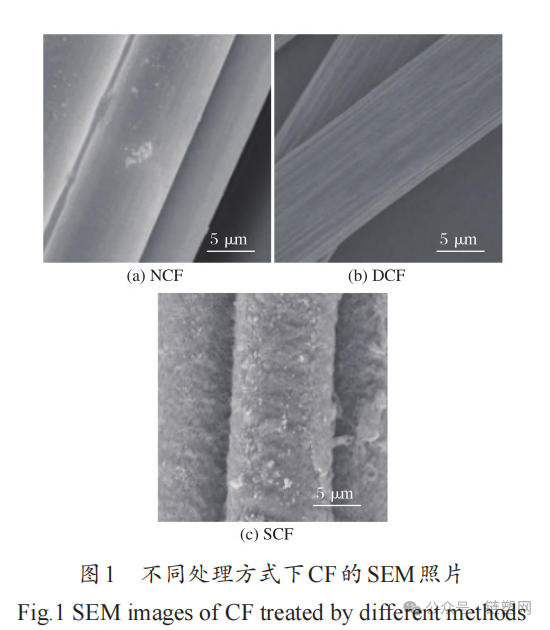

Figure 1 shows SEM images of CF under different treatments. From Figure 1, it can be seen that the untreated NCF surface is relatively smooth. Although some small particles can be observed, their number is relatively low; these small particles are the original sizing agent of CF. The DCF treated with acetone reveals the original surface of the CF, and its surface shows a few shallow grooves; however, the surface remains relatively smooth overall. After treatment with acetone and sizing with PU, the SCF surface has a large number of small sizing particles, and there are also many grooves and wrinkles.

2.1.2 Contact angle between CF and PA6

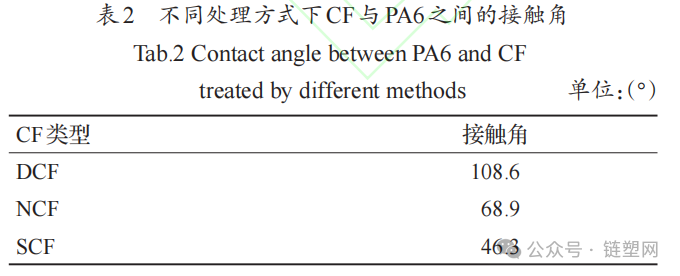

Table 2 shows the contact angles between CF and PA6 under different treatment methods. From Table 2, it can be seen that:

The contact angle of DCF and PA6 after removing the original sizing agent with acetone is 108.6°.

The contact angle of untreated NCF and PA6 is 68.9°.

The contact angle between SCF treated with acetone and then with a water-based PU sizing agent and PA6 is 46.3°.

The contact angle between CF without any other modifying agents and PA6 is the largest, while the contact angle between CF modified with PU sizing agent and PA6 is the smallest, decreasing by 62.3° compared to DCF, indicating that CF modified with PU sizing agent has the best compatibility with PA6.

This is because the surface of CF that has not been modified or coated with any modifier is inert, has low polarity, and is poorly compatible with PA6; the surface of CF coated with a sizing agent has increased polarity, improving compatibility with PA6 and reducing the contact angle; the original sizing agent on CF has poor compatibility with PA6 or the amount of the original sizing agent is limited, resulting in better compatibility of CF coated with PU sizing agent with PA6.The contact angle between SCF and PA6 is the smallest, followed by the contact angle between NCF and PA6.。

2.2 CF Single Fiber Tensile Strength

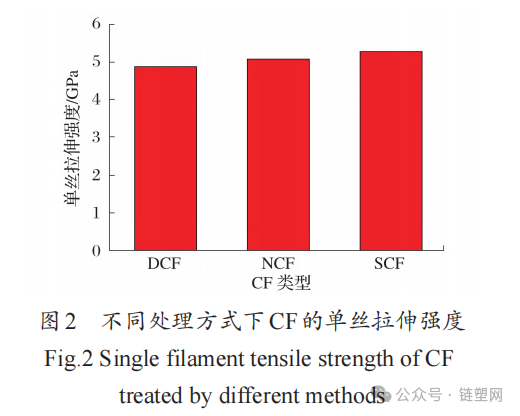

Figure 2 shows the single-filament tensile strength of CF under different treatment methods. From Figure 2, it can be seen that the single-filament tensile strength of DCF is 4.9 GPa, that of NCF is 5.1 GPa, and that of SCF is 5.3 GPa, indicating that SCF has the highest single-filament tensile strength, while DCF has the lowest.

This is because the sizing agent forms a tight encapsulating layer on the CF surface, which can fill the original grooves and defects of CF, thereby improving the integrity of CF and increasing its tensile strength. Moreover, after sizing with waterborne PU, the encapsulation of CF's surface is more thorough and tight (as shown in Figure 1), resulting in the highest tensile strength of SCF. Therefore, the modification effect of waterborne PU sizing agent on CF is relatively good.

Interlayer shear strength of PA6/CF.

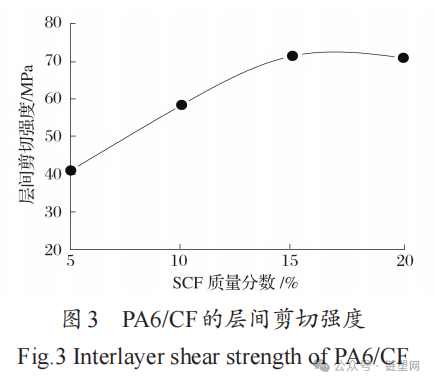

Figure 3 shows the interlaminar shear strength of PA6/CF. From Figure 3, it can be seen that with the increase of SCF content, the interlaminar shear strength of PA6/CF first increases significantly and then slightly decreases, reaching a maximum when the mass fraction of SCF is 15%.

This is because the sizing agent has a large number of active groups on the surface of SCF, which can make SCF evenly dispersed in PA6. The molecules of the PU sizing agent on the SCF surface intertwine, mechanically bond, or form intermolecular hydrogen bonds with PA6, effectively combining SCF with PA6. Therefore, SCF uniformly bears and transmits shear loads.With a certain amount of doping, the interlaminar shear strength of PA6/CF increases with the increase of SCF content. When the SCF content is too high.SCF may come into direct contact or agglomerate, leading to stress concentration and internal defects during processing, preventing SCF from fully utilizing its high mechanical performance advantages.The interlayer shear strength of PA6/CF slightly decreases.。

2.4 Mechanical Properties of PA6/CF

Figure 4 shows the tensile strength and flexural strength of pure PA6 and PA6/CF. It can be seen from Figure 4 that with the increase of SCF content, the tensile strength and flexural strength of PA6/CF first increase significantly and then increase slowly. When the mass fraction of SCF is 15%, the tensile strength and flexural strength reach 218.2 MPa and 300.3 MPa, respectively, which are 316.4% and 198.8% higher than those of pure PA6. When the SCF mass fraction is further increased to 20%, the tensile strength and flexural strength are 219.0 MPa and 301.6 MPa, respectively, only 0.37% and 0.43% higher than those of PA6/15% CF.

This is mainly because the tensile strength and flexural strength of CF are much higher than those of PA6. Adding SCF to PA6 can transmit and bear destructive loads, especially after the surface of CF is modified by sizing agents, the interfacial adhesion between SCF and PA6 is relatively good.The reinforcing effect of SCF on the tensile strength and flexural strength of PA6/CF is significant.However,When the content of SCF is too highAt this point, the contribution of excessive SCF to performance has essentially reached its limit. Excessive SCF can easily lead to decreased dispersion uniformity, causing agglomeration, resulting in processing difficulties, internal defects, and stress concentration.The effect of SCF on improving the tensile strength and flexural strength of PA6/DCF is limited, resulting in a small increase.。

Figure 5 shows the SEM image of the fracture surface of the tensile strength specimen of PA6/CF. From Figure 5, it can be seen that...

When the mass fraction of SCF is 5%~15%SCF is uniformly dispersed in the PA6 matrix, with fractured SCF surrounded by PA6 resin, and the amount of SCF is increasing.

When the mass fraction of SCF increases to20% Some SCF are pulled out, leaving holes, and some SCF are surrounded by very little PA6 resin.

Due to the excessive amount of SCF, agglomeration occurs, and some SCF cannot be completely encapsulated by the PA6 matrix, which easily leads to defects in the composite material system, causing the SCF to be easily pulled out.This further verifies the reason why the tensile strength and bending strength first increase significantly and then grow slowly.

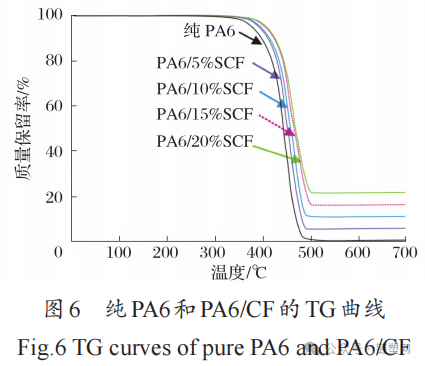

2.5 Heat Resistance of PA6/CF

Figure 6 shows the TG curves of pure PA6 and PA6/CF. It can be seen from Figure 6 that the initial thermal decomposition temperature (t₀) of pure PA6 is 346°C when SCF is not added, and the temperature corresponding to the maximum thermal decomposition rate (t...maxThe temperature is 451°C, and the final mass retention rate (w).losThe thermal decomposition of PA6 mainly involves the initial breakdown into aliphatic hydrocarbons and oligomers, eventually producing H₂O and CO₂. As the SCF content increases, the thermal decomposition curve of PA6/CF shifts upward, with t₀ and t.max: and : Translate the above content into English and output the translation directly without any explanation.losThe increasing trend indicates that the thermal stability of PA6/CF has improved.

When the mass fraction of SCF is 5%, the t₀ of PA6/CF is 357℃.maxThe above content translates to English as: "At 465℃, w".los6.9%

When the mass fraction of SCF is 10%, the t₀ of PA6/CF is 369℃.maxFor 479℃, wlos For 12.0%;

When the mass fraction of SCF is 15%, the t₀ of PA6/CF is 382℃.maxFor 493℃, wlos16.8%.

When the mass fraction of SCF is 20%, the t₀ of PA6/CF is 383℃, tmaxFor 495℃, wlos21.7%.

It can be seen that when the mass fraction of SCF is 5%~15%, the thermal stability of PA6/CF improves rapidly. Compared with pure PA6, t₀ increases by 36℃ and t_max increases by 42℃. When the mass fraction of SCF is 20%, the rate of improvement in the thermal stability of PA6/CF slows down. Compared with the mass fraction of 15% SCF, t₀ and t_max only increase by 1℃ and 2℃, respectively. Additionally, the increase in w_los of PA6/CF is basically close to the increase in SCF content.

The reason for the above results is that the heat resistance of CF in SCF is much higher than that of PA6. The addition of SCF improves the thermal stability of PA6/CF, hence the increase in t₀ and t_max. When the mass fraction of SCF reaches 15%, the effect of SCF on improving the thermal stability of PA6/CF basically reaches its maximum. Therefore, further increasing the mass fraction of SCF to 20% does not result in a significant change in the thermal stability of PA6/CF. Although the addition of SCF enhances the thermal stability of PA6/CF, PA6 molecules continue to decompose at high temperatures. SCF mainly inhibits the decomposition rate of PA6 and has little effect on the decomposition residue of PA6. Additionally, the PU sizing agent on the surface of SCF also decomposes at high temperatures, so the increase in the w_los of PA6/CF is close to the variation in the SCF content.

3. Conclusion

The surface of DCF is relatively smooth; the surface of NCF contains the original sizing agent and some small particles, but it is also relatively smooth; the surface of SCF is covered with a sizing agent, contains a large number of small particles, and has formed many grooves and wrinkles. The contact angle between DCF and PA6 is 108.6°, between NCF and PA6 is 68.9°, and between SCF and PA6 is 46.3°, indicating that DCF without additional coating of other modifiers has the worst compatibility with PA6, while SCF modified with PU sizing agent has the best compatibility with PA6. The monofilament tensile strength of DCF is the lowest, while that of SCF is the highest.

As the SCF content increases, the interlaminar shear strength of PA6/CF first significantly improves and then slightly decreases. The interlaminar shear strength reaches its maximum when the mass fraction of SCF is 15%.

With the increase of SCF content, the tensile strength and flexural strength of PA6/CF both first increase significantly and then increase slowly. When the mass fraction of SCF is 15%, the tensile strength and flexural strength are improved by 316.4% and 198.8% compared to pure PA6, respectively.

As the content of SCF increases, the thermal stability of PA6/CF gradually improves. When the mass fraction of SCF is 5% to 15%, the thermal stability of PA6/CF increases rapidly; compared to pure PA6, t₀ increases by 36°C and t_max increases by 42°C. When the mass fraction of SCF is 20%, the rate of improvement in thermal stability of PA6/CF slows down. Considering both cost and performance, the optimal mass fraction of SCF is 15%.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory