How Nylon Modification Enterprises Enhance Product Value Through Aging Resistance Technology?

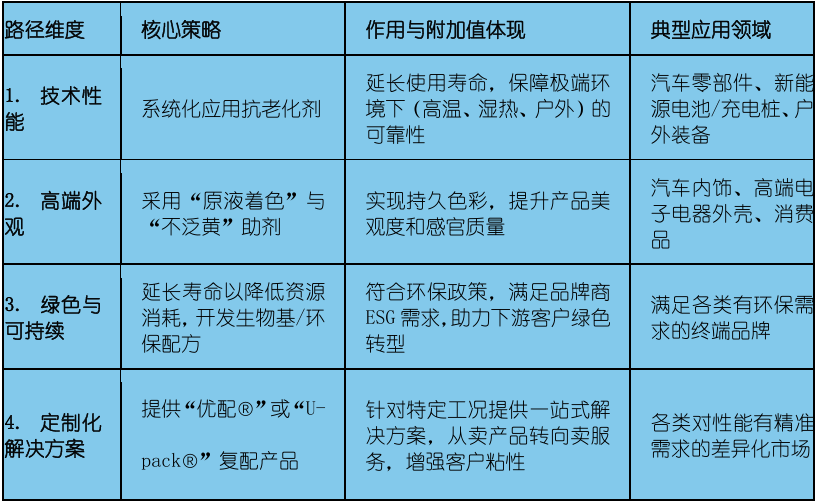

For nylon modification enterprises, enhancing product added value through anti-aging technology is crucial, focusing on transforming this technology from a cost item.Transform into a key value tool to address customer pain points, expand into high-end markets, and meet environmental demands.Companies can achieve this through the following four strategic levels.

Key Path to Enhance Product Added Value

Implementation Path 1: Systematic Technology to Ensure Core Performance

This is the foundation of added value. Enterprises need to deeply understand the complex mechanisms of nylon aging (thermal oxidative aging, photo-oxidative aging, hydrolysis, etc.) and design targeted solutions for different application scenarios.

Synergistic formulation is key: the effect of a single additive is limited. An effective solution often involves the synergistic use of a primary antioxidant (such as hindered phenol RIANOX® 1098), a secondary antioxidant (such as phosphite RIANOX® 686), and a light stabilizer (such as hindered amine RIASORB® UV-660), collectively blocking the aging chain from different mechanistic angles.

Addressing Harsh Environments: For example, in the high-temperature and high-humidity environments inside new energy vehicle battery packs and charging piles, it is necessary to choose hydrolysis-resistant and low-volatility antioxidants like RIANOX® 686 to ensure long-term stability.

Achieving Path Two: Entering the High-End Market with Outstanding Aesthetic Quality

For visible components such as consumer electronics and automotive interiors, the durability of appearance directly determines the product's quality and price.

Addressing the "yellowing" issue: Nylon is prone to yellowing under light and heat exposure. It is essential to use special light stabilizers (such as Eversorb® PA3) that do not affect the initial color of the product.

Promote the "liquid dyeing" technology: Add color masterbatch during the spinning or modification stage to eliminate the need for post-dyeing processes. The nylon colored yarn produced this way has uniform color, high color fastness, does not fade, and the production process is more environmentally friendly. Market practice has proven that the price of such high-end colored yarn is several thousand yuan higher per ton than that of ordinary fibers.

🌱 Path Three for Implementation: Transforming Green Sustainability into Brand Premium

Combining anti-aging technology with environmental trends can inject new value dimensions into the product.

Extending lifespan is the greatest environmental protection: anti-aging technology directly prolongs the service life of materials, reducing resource waste and carbon emissions caused by premature replacement, which is itself an important contribution to sustainability.

Develop a green product line: for example, using bio-based nylon (such as PA56) as the substrate, paired with environmentally friendly anti-aging agents. Lianlong has also launched water-based antioxidants and other eco-friendly products.

Path Four: Transition from Product Sales to Solution Services

A key step in providing high added value is upgrading from a standardized product supplier to a technology service provider.

Customized Formulation (U-pack®): Providing tailored additive packages to address specific issues in customer applications (such as UV-C disinfection lamp resistance and resistance to specific chemicals), offering a one-stop solution.

Participate in early-stage research and development with customers: Collaborate closely with leading downstream clients to jointly develop new materials that meet future demands (such as higher temperature resistance and longer warranty periods), achieving technology binding and mutual growth.

Industry trends to watch

Localization and substitution: Domestic companies, represented by Lianhong, have broken the international monopoly on certain high-end anti-aging agents. This provides modification companies with a more cost-effective and supply-secure option.

Regulations and standards-driven: The requirements for material durability and environmental protection are becoming increasingly stringent both domestically and internationally. Enterprises with mature anti-aging solutions will have a greater compliance advantage.

In summary, nylon modification enterprises should regard anti-aging technology as a systematic project. While ensuring basic performance, they should keenly capture the downstream industries' demands for high-end, green, and customized solutions, precisely transforming technical advantages into customer value and market premiums.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories