Indonesia Plans to End Electric Vehicle Tariff Exemption Policy by End of 2025

According to a report by Nikkei, Indonesia is expected to end the electric vehicle tariff exemption policy by the end of 2025. This preferential policy had helped Chinese electric vehicle manufacturers like BYD increase their sales in Indonesia, but it also impacted the production of local factories in Indonesia.

Image source: BYD

An official from Indonesia's Ministry of Industry stated at an event in the country's capital, Jakarta, last week that there have not yet been discussions with other departments about extending the electric vehicle tariff exemption policy, and it is highly likely that this exemption will expire at the end of this year.

Previously, Indonesia exempted electric vehicles from import duties and luxury goods taxes in order to promote the adoption of electric vehicles. Chinese car brands have benefited the most from this policy. Indonesia's electric vehicle sales have performed strongly, with approximately 42,000 units sold in the first seven months of this year, representing a year-on-year surge of about 140%, and accounting for nearly 10% of the country's total new car sales.

BYD is one of the main beneficiary companies, as all models it sells in Indonesia are imported. In July 2024, BYD launched the popular M6 electric vehicle in Indonesia, priced comparably to gasoline cars. Currently, BYD's market share in Indonesia's electric vehicle market has exceeded 50%.

Meanwhile, Japanese automakers with factories in Indonesia are facing difficulties. As more affordable electric vehicles flood the Indonesian market, the overall market share of Japanese car companies like Toyota in Indonesia has fallen below the usual 90%.

A representative of the Indonesian Automotive Industry Association pointed out that the factory capacity utilization rate of the country's automotive industry has dropped from 73% to 55%, and stated that although the country's tariff exemption policy has promoted the adoption of electric vehicles, it has also hindered the development of the country's automotive industry.

The current focus is on whether Chinese automakers, who have long benefited from Indonesia's policy dividends, can fulfill their commitments to local production in Indonesia. The Indonesian government requires automakers to have local production volumes that meet or exceed import volumes, and to start local production in Indonesia before 2027.

BYD is building a factory in West Java Province, Indonesia, with plans to start production in early 2026 and an annual output target of 150,000 vehicles. However, overall, it remains uncertain whether other Chinese automakers will follow suit and establish local production in Indonesia.

In addition, due to a significant decline in the purchasing power of Indonesia's middle class, overall new car sales have decreased despite strong performance in electric vehicle sales. The stagnation in demand for cars in the Indonesian market means that expanding local production capacity is unlikely to yield substantial returns for car manufacturers.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Four Major Chemical New Material Giants Sell Off and Shut Down Again!

-

Covestro faces force majeure!

-

DuPont to Spin Off Nomex and Kevlar Brands for $14.4 Billion: Is Aramid Fiber Still Attractive?

-

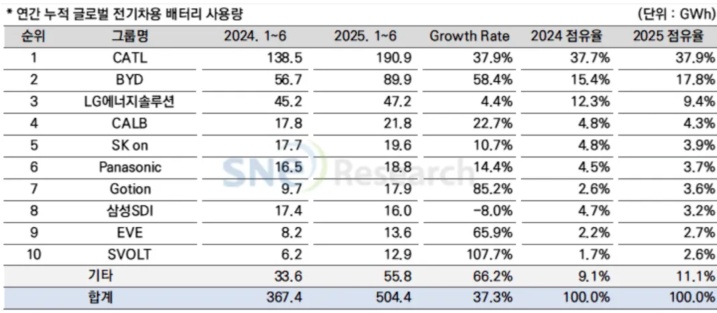

Massive Retreat of Japanese and Korean Battery Manufacturers

-

Napan Unveils Thermoplastic Composite Three-in-One Power System Solution, Battery Cover Weight Reduced by 67%