K 2025 Highlights | Four Core Advantages Attract Global Customers, YIZUMI Secures Nearly Ten Million Level Orders On-Site

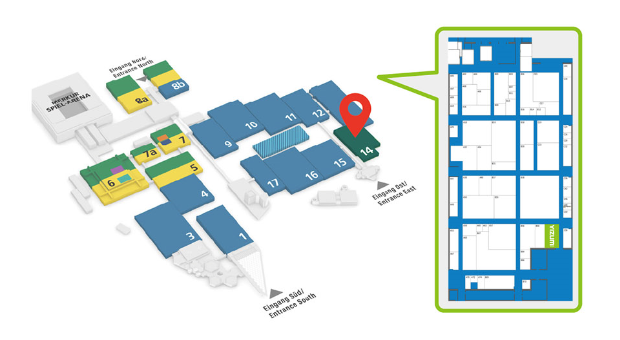

On October 14 local time, K 2025 continues to be held at the Düsseldorf Exhibition Center in Germany. The booth of Yizumi Rubber Machinery (Booth No.: C59, Hall 14) is always bustling with people, reflecting the global rubber and plastic industry's urgent demand for "efficient, convenient, energy-saving, and intelligent" equipment.

It is worth mentioning that the YL3-V350F model of the A3 series from Yizhimai Rubber Machine has won nearly ten million-level orders from a leading precision rubber products company in the United States at the exhibition, thanks to its four core advantages of "efficiency, convenience, energy-saving, and intelligence." This trust reflects the client's comprehensive and in-depth recognition of Yizhimai Rubber Machine and serves as the strongest proof of the outstanding quality and exceptional performance of the A3 series.

Swipe left or right to see more.

A3 model

01

Brand new upgrade, intelligent and efficient

The A3 series rubber machine has achieved a significant technological breakthrough. Its ingenious design, excellent craftsmanship, and outstanding performance not only reflect the company's persistent pursuit of technological innovation but also deeply demonstrate the company's profound understanding of customer needs.

The model is equipped with a control system jointly developed by Yizhi Mi and KEBA, with a comprehensive enhancement of the hardware infrastructure. The command response speed and data processing rate have achieved a qualitative leap, providing strong power for complex multitasking and high-load operating scenarios.

In addition, with the new software upgrade, this model features a streamlined operating process, precise control accuracy, and real-time monitoring of production status, significantly reducing operational difficulty and reliance on technical engineers. It can quickly initiate an efficient operating mode and easily adapt to future automation and intelligent upgrade requirements.

Modular Empowerment Customization

02

Precision services multiply benefits

The A3 series rubber machines adopt a deep modular design, allowing for the free selection and combination of serialized functional modules to meet various process application needs, providing customers with low-cost, fast delivery, and highly reliable customized solutions.

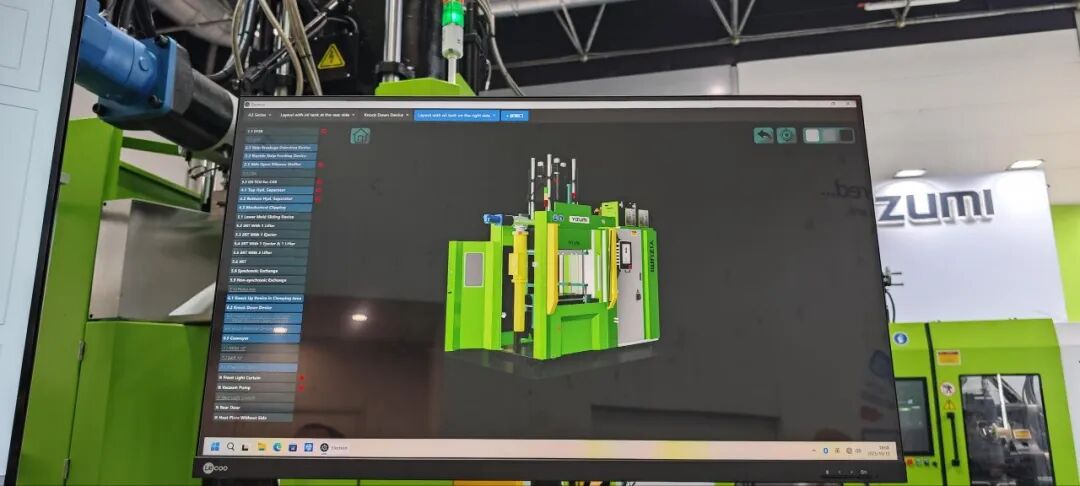

At the same time, this model launched a brand-new Simple 4D digital display platform at the K 2025 exhibition. Customers can combine and select A3 series product installations both on-site and online, using 3D models and animations to fully, clearly, and visually understand the features and advantages of the A3 products. The visible and accessible Simple 4D platform makes the selection process simpler and more technologically advanced for customers.

Energy-saving design aids in low carbon.

03

Green Practice Enhances Development Quality

The A3 series rubber machine adopts the latest generation of energy-saving technology, conducting in-depth research on the efficiency, speed, pressure, temperature, vibration, and noise of each component in the hydraulic and temperature control systems. Its continuous innovation in low-carbon energy saving has resulted in a 25% reduction in hydraulic oil usage, a 40% reduction in heat transfer oil usage, and a more than doubling of equipment lifespan.

The various devices and the entire A3 series rubber machine have undergone 279 durability tests, totaling over 300,000 hours. Combining theoretical calculations, simulation modeling, and actual production application scenarios, we ensure that the performance indicators and reliability of every detail are fully verified, effectively guaranteeing the stability of customer production and product quality.

At the same time, by introducing the TPM equipment reliability preventive management system, a trinity approach of equipment inspections and predictive maintenance management is implemented to make equipment maintenance easy and convenient. The service network and parts centers spread worldwide enhance the accessibility of spare parts, providing comprehensive support for efficient production.

Based on the IPD product development system, an in-depth analysis of customer needs for Equipment Lifecycle Management (ELCM) is conducted across five major stages: planning and design, procurement and installation, operation and maintenance, upgrading and modification, and decommissioning and disposal. Through stages such as technical pre-research, product development, and small-scale market release, the A3 series rubber machines offer first-class user experience, providing customers with production assurance solutions and services, thereby promoting the intelligent development of the rubber injection molding equipment industry.

To learn more about Yizhim Rubber Machines, we warmly welcome all business guests to visit our booth: C59, Hall 14, from now until the 15th.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

India's Q3 Smartphone Shipments Rise 3%; Japanese Mold Factory Closures Surge; Mercedes-Benz Cuts 4,000 Jobs

-

Ascend's Restructuring Plan Approved! Jwell Launches Global Acceleration Plan; Nexperia Chip Crisis Threatens Global Auto Production

-

Dow To Restart Pe Units 5 And 7 This Week, Recovery Date For Unit 6 Remains Undetermined In The United States (US)

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

The Roller-Coaster Behind Sanhua Intelligent Controls' Stock Price: What Are the Advantages of Automotive Thermal Management Companies Crossing Into Humanoid Robots?